Wheel speed sensors generate signals about the speed of each wheel of the vehicle, which are transmitted to the electronic control unit of the hydraulic unit.

Wheel speed sensors generate signals about the speed of each wheel of the vehicle, which are transmitted to the electronic control unit of the hydraulic unit.

The operation of wheel sensors is based on the principle of electromagnetic induction.

When the wheel rotates, the teeth and cavities of a special rotor pass by the sensor and induce an electric signal in the sensor winding, the frequency of which is proportional to the angular velocity of the wheel and the number of teeth on the rotor.

The electronic control unit logically processes the signals about the speed of the wheels and, depending on their state (excessive acceleration or deceleration of the wheel), sends control commands to the hydraulic modulator.

Based on the commands received, the hydraulic modulator, turning on or off the electromagnetic valves, reduces, increases or maintains a constant pressure of the brake fluid in the wheel brake cylinders, thereby ensuring optimal regulation of braking forces

We remove the sensors during repair work or when replacing a faulty sensor

We prepare the car for the task and install it on a lift or inspection pit

We disconnect the negative terminal of the battery

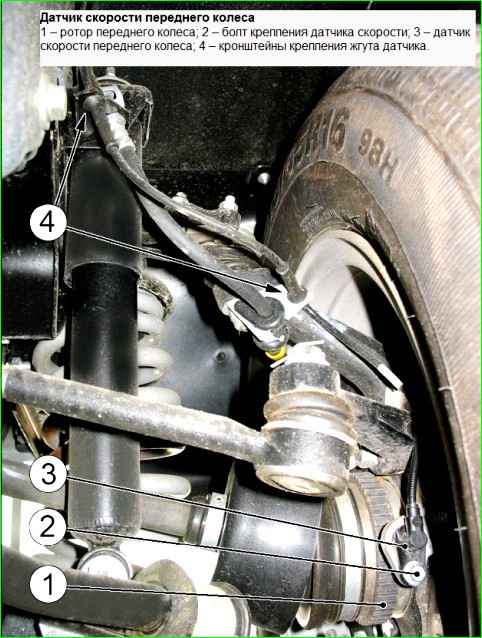

Removing the front wheel ABS sensors

When removing the right speed sensor, unscrew the nuts securing the adsorber bracket and move the adsorber to the side (article - Catching fuel vapors Niva Chevrolet)

When removing the left speed sensor, disconnect the "plus" terminal from the battery and remove it from the car.

Disconnect connector 2 of the front wheel speed sensor harness from the front wire harness.

Remove seal 1 and push the sensor harness connector into the hole in the vehicle wing.

Raise the vehicle to a height convenient for performing work

Disconnect the front wheel speed sensor harness from bracket 4

Unscrew bolt 2 securing sensor 3 to the front wheel speed sensor bracket on the steering knuckle

Remove the front wheel sensor

Installation

Install the front wheel speed sensor in the reverse order

When installing, take into account the gap between the sensor and the rotor tooth should be 0.72-1.33 mm. Tightening torque of the sensor mounting bolt is 8±2 Nm.

Removing and installing the rear wheel speed sensor

Prepare the car for the task and install it on a lift or inspection pit

Disconnect the negative battery terminal

Install the car on a lift or inspection pit

Lift the car to a convenient height if the car is on a lift

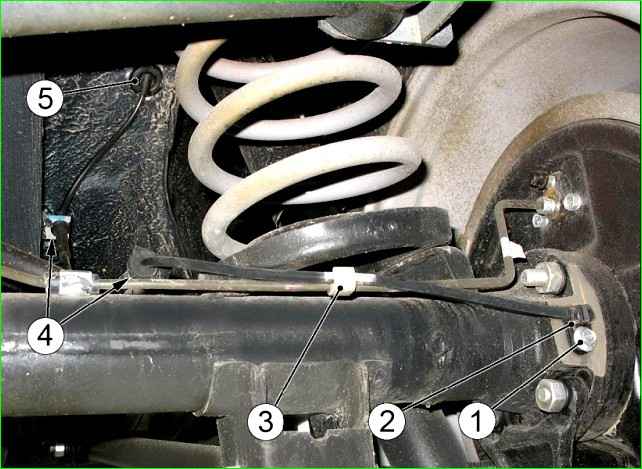

Remove the rubber seal 5 of the sensor harness from the hole in the body

Carefully remove the harness and plug connector from the body. Disconnect the shoe

Disconnect the speed sensor harness from brackets 4 and clamp 3.

Unscrew bolt 1 securing sensor 2 to the rear axle

And remove the rear wheel speed sensor

Installation

Install the rear wheel speed sensor in the reverse order

Before installation, lubricate the sensor sealing ring with transmission oil

The gap between the sensor and the rotor teeth should be 0.13-1.12 mm. The tightening torque of the sensor mounting bolt is 8±2 Nm.

If it is necessary to replace the front wheel rotor, it is necessary to replace the drive or the outer CV joint

If it is necessary to replace the rear wheel rotor, we replace the axle shaft assembly.