During various impacts, body parts undergo deformation, which sometimes cannot be determined visually

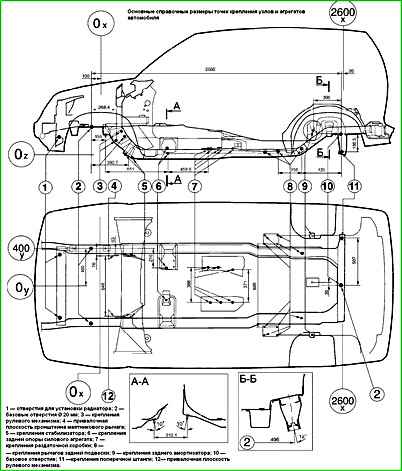

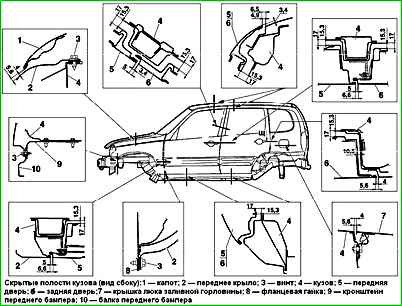

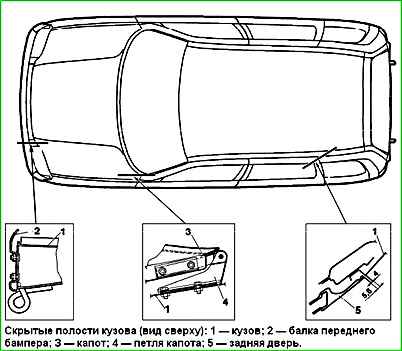

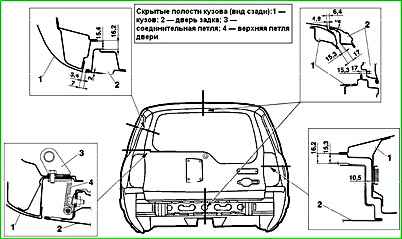

Therefore, for more accurate body straightening and deformation assessment, reference dimensions should be used.

Reference points are shown in Figure 1.

The frame structure is calculated so that the impact energy is absorbed when struck from any side.

The body parts that form the interior must undergo the minimum possible deformation, in other words, the body must eliminate or reduce the severity of the accident consequences.

Bumpers are used to absorb the impact energy during a collision.

To ensure safety inside the car - a soft instrument panel, pillar linings, and the design of other elements.

Seat belts also play a certain role in ensuring safety.

The body frame includes the following elements: the front end, floor, sidewalls, roof with windshield frame, rear panel and load-bearing elements - side members, crossbars, pillars.

Plumage parts: front body panels and hinged units - hood, tailgate, front fenders.

All parts and units, except for hinged elements and front fenders, are connected by contact spot welding, and significantly loaded frame parts are additionally welded by electric arc welding.

The front end consists of a vertical shield, mudguards, crossbars, air intake box, amplifiers and other small parts.

The mudguards are connected to the front side members.

The floor of the car includes the front, middle and rear floors.

The front, trough-shaped, contains a tunnel for placing exhaust pipes, fuel and brake lines.

The tunnel serves to protect these parts from damage and increase the rigidity of the floor.

The side members are welded along the floors. The front, middle and rear cross members are also welded to the floor.

The body sides consist of outer and inner panels.

The outer ones are integral with the central and rear pillars and with the side window openings.

The inner body panels structurally combine the outer arches of the rear wheels and the pillar reinforcements.

Behind the reinforcement, on the right side, there is a niche for installing a gasoline vapor collector, grooves and flanges for door and glass seals.

The removable units are the doors, tailgate, hood, front fenders, bumpers, radiator grille, etc.

The fenders are attached to the frame with self-tapping bolts; gaskets are installed under the fenders to reduce vibration. The hinges of the front doors and hood allow for adjustment of their position.

To increase the rigidity and strength of the body, reinforcing pads, brackets, and stiffeners are used.

To protect against mechanical damage and create thermal and noise insulation, the lower outer part of the body, wheel mudguards, and inner surfaces of the wings are covered with an anti-corrosion material, and the floor of the cabin and trunk are covered with special vibration-damping mastics.

Before welding areas subject to corrosion, the welded parts are coated with a special preservative compound.

The outer and inner surfaces of the body are treated with special compounds, as a result of which water-insoluble protective compounds are formed on them.

The outside of the body is painted with synthetic enamels.

Body elements that increase safety

The most probable speed of cars during collisions is 80 km/h for frontal and rear impacts and 64 km/h for side impacts.

These figures are the initial ones for calculating the strength of bodies and developing design measures to ensure the safety of passenger cars.

Improving vehicle safety includes "active" safety measures that help prevent accidents, and "passive" safety measures that are incorporated into the vehicle design to ensure the safety of the driver and passengers if an accident cannot be prevented.

"Active" vehicle safety measures include the development of designs for parts and assemblies that ensure braking efficiency and the reliability of the brake drive, anti-lock braking systems that allow the vehicle to move in a given direction when braking, as well as measures to increase visibility of the road and surroundings from the driver's seat.

This includes the installation of a dual-mode windshield wiper, heater, and fan that prevent icing and fogging of the glass.

"Passive" safety measures provide for the prevention or reduction of injuries to the driver and passengers in an accident.

The result is achieved by ensuring protective zone around each passenger, limiting the ability of the driver and passengers to move relative to the seat, reducing the level of injuries from impacts with the interior surfaces of the passenger compartment, ensuring the ability of the driver and passengers to exit the vehicle after an accident.

Ensuring the protective properties of the body consists of developing and implementing such design solutions that allow a protective zone to be formed around the driver and passengers.

A rigid passenger compartment in combination with energy-absorbing front and rear parts of the body allows for a reduction in the acceleration of people at the moment of impact and provides the best possible protective zone around passengers.

Bodies of this design are built according to the principle of progressive energy capacity, i.e. with a given degree of reinforcement of some parts with the maximum permissible crushing of others in order to absorb the impact energy.

Very high loads during impacts in different directions (longitudinal, transverse and vertical) act on the doors, door hinges and door locks.

The doors protect the passenger compartment from penetration of foreign objects during an accident and should not open during an impact so that passengers cannot fall out of the body.

The door locks are equipped with a reliable locking system that prevents their accidental unlocking under the action of inertial loads or upon impact during an accident, since the doors themselves are not excluded from the general rigidity contour of the body passenger compartment.

To protect the driver and passengers in side collisions, protective box-section beams are built into the body doors.

The beam is located inside the door between the drop-down window and the outer panel.

In addition to protecting the passenger compartment from penetration by the striking vehicle, the beams seem to move the struck vehicle to the side.

Bumpers in modern passenger cars have protective properties combined with decorative features created by designers.

Today, wide-profile bumpers with the most rounded shapes are installed.

Their protective properties are high, bumpers protect the car from damage in minor collisions and must comply with international safety standards.

Systems that limit the movement of the driver and passengers inside the body include seats and seat belts.

The level of injuries in accidents is reduced most effectively if the design of the car provides for reliable fastening of the passenger to the seat, which, in turn, should not come off the floor of the body under the influence of emergency overloads.

The seats are secured so that they withstand safety requirements for longitudinal loads acting in both directions, as well as for torsional moment.

The seat belts have a simple locking device that ensures reliable fastening and, if necessary, allows for quick unfastening.

In the working position, the belts provide sufficient freedom of movement for the driver and do not interfere with driving.

Calculations and practice show that seat belts reliably protect passengers in a frontal collision at a speed of up to 80 km / h.

The next element is the steering wheel.

The safety of the steering wheel consists in eliminating cases of severe injury to drivers in frontal collisions of cars.

In accordance with the requirements during testing of a car for a collision with a reinforced concrete barrier weighing at least 70 tons at a speed of 48.3 km/h the upper part of the steering column and the steering shaft must not move rearward horizontally and parallel to the longitudinal axis of the vehicle by more than 12.7 cm.

If the steering column collides with a torso form that strikes the column with a relative velocity of at least 24.1 km/h, the force with which the steering column acts on the front of the torso form must not exceed 11.35 kN (1,135 kgf).

Car windscreens must comply with the requirements of the UN EEU regulations.

For example, VAZ car windows are triple-layered, they consist of two profiled polished glasses with an interlayer of sticky transparent plastic.

The main advantage of a laminated windscreen is that cracks during an impact spread from the center of the impact, the fragments are held on the plastic interlayer, the glass retains its transparency, shape and does not fall out of the body opening.

The rear and side windows are made of tempered glass, they undergo special heat treatment, providing increased strength.

When destroyed, these glasses break into many small fragments without sharp corners and edges that can cause deep injuries.

Headrests must exclude severe injuries, expressed in damage to the cervical vertebrae and vertebrae of the upper chest.

Such injuries are caused when a moving car hits the rear of a stationary car.

In this type of road accident, the headrests must comply with the international UNECE rules in terms of strength, and their design must exclude the possibility of injury to the rear passenger in a frontal collision of cars.

The interior of the body is of great importance. It includes interior trim that must meet modern aesthetic and ergonomic requirements.

The instrument panel is made without protruding parts and sharp edges, with convenient placement of control and measuring instruments and controls.

The energy capacity of the panel is ensured not only by soft upholstery, but also by introducing thin-sheet steel panels into the frame structure that are capable of absorbing energy upon impact due to their partial deformation.

The armrests, doors and sun visors are lined with soft materials.

The door handles, window lifters, switch buttons and door locks are placed and made so that in the event of an impact the passenger cannot be injured.

Car damage in accidents

The greatest number of car collisions occur at the front, slightly fewer at the rear and the least at the side.

Body damage resulting from collisions is divided into three categories. The first category includes very severe damage, which requires replacement of the body.

The second category includes moderate damage, in which most parts require replacement or complex repair.

The third category includes less significant damage - holes, tears in the front panels, dents and scratches received during an impact while driving at low speed.

This damage does not pose a danger to passengers and the driver during operation of the car, although its appearance does not meet aesthetic requirements.

The most destructive damage to the body occurs in frontal collisions - impacts inflicted on the car directly in the front part of the body or at an angle of no more than 40-45° in the area of the front pillars.

Such collisions usually occur between two oncoming vehicles, the speeds of which are added together, which creates high impact loads.

The amount of energy that must be absorbed in such collisions is enormous: about 80-100 kJ for a car weighing about one ton.

This energy is absorbed during the deformation of the car in less than 0.1 s.

The car body is destroyed, especially its front part, and the high loads acting in the longitudinal, transverse and vertical directions are transmitted to all adjacent parts of the body frame and especially its power elements.

Let's consider the above with examples

So, the frontal collision of the car occurred with the front part of the body in the area of the left front wing, side member and left headlight.

The front panel, wings, hood, mudguards, front side members, windshield frame and roof receive destructive damage.

This deformation is established merges visually.

Invisible deformation occurs in the front, central and rear pillars on both sides, in the left front and rear doors, in the left rear wing and even in the rear panel of the trunk.

Or: the impact occurred with the front part of the car body at an angle of 40-45°.

The front fenders, hood, front panel, mudguards, front side members received destructive damage.

It is almost impossible to restore the base points of the front part of the body without replacing the deformed parts with new ones.

In this case, it is necessary to restore the dimensions of the front door openings and the position of the front and central pillars, since the force loads were transmitted through the front doors to the front and central pillars of the body, creating compressive forces on the threshold and the upper part of the side of the body.

Another example: the impact was inflicted from the side on the front part of the car body in the area of the junction of the front panel with the front parts of the side member and the left wing.

Both front wings, the front panel, mudguards, side members, and hood sustain destructive damage.

Tensile forces disrupt the opening of the left front door, compressive forces cause deformation in the opening of the right door and in the side of the left front door.

The front and center pillars also receive significant force overloads and deviate from their original position.

The impact is received from the side in the front pillar of the car body on the left side.

At the same time, the left front pillar, windshield frame, roof, floor and side members of the front floor, front panel, hood, fenders, mudguards, and front side members are significantly deformed.

The front of the car body shifted to the left, the threshold and the upper part of the right side took on tensile loads, and the center and rear racks – compressive loads; the right mudguard in conjunction with the front pillar experienced tearing forces.

During an external inspection of the emergency body, it is possible to establish the presence of distortions in the extension or retraction of the doors, trunk lid and hood relative to the fixed surfaces of the body parts.

Violation of the uniformity of gaps along the mating lines of the hinged and fixed parts also indicates the presence of deformations in the body frame parts caused by the accident.

It should be remembered that an external inspection cannot determine deviations in the linear dimensions of the body openings and geometric parameters at the base points of the body base.

For these purposes, it is necessary to use measuring instruments, special control devices and stands.

Body damage that occurred during operation

We are talking about less significant damage to the body that occurred during the operation of the car and worsens the appearance.

Dents appear as a result of residual deformation due to impact, improper repair, and also due to poor-quality body assembly.

Dents can be simple and easy to repair, or complex - with sharp bends and folds or located in places that are difficult to repair.

Cracks are common damage to the body.

They can appear anywhere as a result of metal overstress (impacts, bends), as well as as a result of a weak connection of units and parts and insufficient strength of the structure.

Tears and holes are divided into simple, which take the form of a crack after straightening the metal, and complex, requiring patches when repairing the damaged area.

Tears in body parts are characterized by the size of the torn part of the panel or plumage.

Large tears are often repaired by installing complex profile inserts, and in some cases a complete replacement is made details.

Stretched metal surfaces are distinguished by their location: on the panel surface in the form of a bump and in the flanging of parts (stretched sides and edges).

Corrosion in its external manifestation can be uniform, when the metal is destroyed evenly over the entire surface, and local, when the metal is destroyed in individual areas.

The latter form of corrosion is detected by dark spots or deep black dots on the metal, it is more dangerous, since the metal can quickly deteriorate with the formation of through holes.

Violation of welded joints occurs in the nodes of parts that are connected by spot welding, and in continuous welded seams of the body.

Violation of riveted seams is the result of weakening or shearing of rivets, as well as wear of holes for bolts and rivets.

Bending, distortions and twisting usually appear as a result of emergency load.

Distortions can be inter-node and in the plane of one unit or part (distortion in the doorway of the body, distortion in the door itself, deflection of the floor).

Wear of holes and rods occurs as a result of rolling friction (axles and holes in door hinges) or loosening of the unit fastening with rivets or bolts; wear of surfaces - due to systematic load applied to the surface surfaces, for example, when transporting abrasive cargo in the body of a car.

When repairing cars, two main areas of dimensional control are used: mechanical systems (feelers, tape measures, templates, etc.) and optical systems that project a laser beam onto control points.