Replacing piston rings of the YaMZ diesel engine

Piston rings are replaced during engine repair in the following cases:

- - when the engine has operated for more than 150 thousand km;

- - completely or partially worn grooves on the working surface of the second and third compression rings;

- - the presence of scoring on the outer cylindrical surface of the rings.

To replace piston rings, first dismantle the piston with the connecting rod with the cylinder head and sump removed.

The engines are equipped with oil cooling of the pistons.

When dismantling the piston group on the specified engines, first remove the piston cooling nozzles to avoid their breakage, for more easy piston extraction, clean the carbon deposits from the upper belt of the cylinder.

Unscrew the connecting rod cap mounting bolts, remove the cap and remove the piston with the connecting rod through the cylinder.

To disconnect the connecting rod from the piston, remove the piston pin retaining rings, heat the piston in an oil bath to 80°C and remove the piston pin.

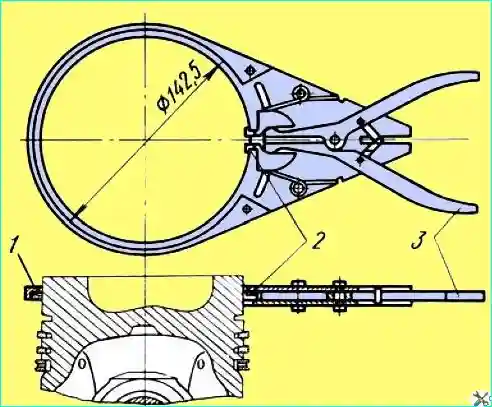

Fig. 1. Piston ring pliers: 1 - piston ring; 2 - pliers jaws; 3 - handle

To remove piston rings, put the pliers (Fig. 1) on the ring, insert the jaws of pliers 2 into the ring lock and, squeezing the handles of pliers 3 until they stop

Fig. 2. Removing and installing piston rings on the piston

Carefully remove the ring from the groove and remove it from the piston (Fig. 2).

Install the piston rings in the reverse order.

Carefully clean the piston from carbon deposits, protecting it from damage (especially the end surfaces of the grooves for the piston rings).

Before assembly, thoroughly wash all parts and blow out the oil channels with compressed air.

Assemble the piston with the pin by lightly pressing with your hand, while generously lubricating the hole in the piston and the pin with engine oil. Pressing the pin into the piston is not allowed.

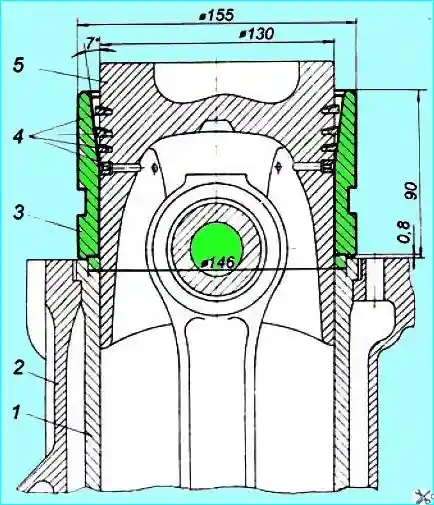

Fig. 3. Mandrel for installing the piston into the cylinder liner: 1 - cylinder liner; 2 - cylinder block; 3 - crimping device; 4 - piston rings; 5 - piston

In order to install the piston assembly with piston rings and connecting rod into the cylinder liner, first compress the rings by pressing them into the piston grooves.

To compress the rings, use a mandrel (Fig. 3) with a conical inner surface and a flange that allows you to correctly center the mandrel on the cylinder liner.

After installing the piston in the mandrel, seat it in the cylinder liner.

When assembling the piston with the connecting rod and installing them on the engine, meet the following requirements:

- 1. The piston and liner must be of the same size groups.

- 2. Install the compression rings with the "top" stamp toward the piston bottom.

- 3. Move the locks of adjacent piston rings in opposite directions in the plane of the piston pin.

- 4. Install the piston so that the offset combustion chamber in the piston is directed inside the engine, towards the fuel pump.

On YaMZ-2Z6NE2, -BE2 engines with individual cylinder heads, pistons with a central combustion chamber are used.

Install the piston in the sleeve so that the arrow on the piston is directed into the engine camber, towards the fuel pump.

In this case, the grooves on the piston bottom for the valves will be offset relative to the center of the cylinder towards the exhaust manifolds.

- 5. The mating marks on the connecting rod and cover must be the same.

- 6. Dirt, burrs and nicks on the splines of the connecting rod and cap are not allowed.

- 7. Lubricate the threads and bearing ends of the heads, connecting rod cap fastening bolts with engine oil and tighten in two stages, starting with the long bolt, first with a torque of 100 Nm (10 kgfm), finally with a torque of 200 - 220 Nm (20 - 22 kgfm).