The power steering pump (Fig. 1) is a double-acting vane type, i.e., during one revolution of the pump rotor, two complete suction cycles and two discharge cycles are performed

The pump rotor has vases in which the vanes are placed. The blades must move freely in the vases, without jamming.

In the suction cavities, oil enters the space between the blades and is then forced out into the discharge cavities.

The oil is forced out as a result of the decrease in volume between the blades, since the rotor rotates inside the stator, which has a special profile.

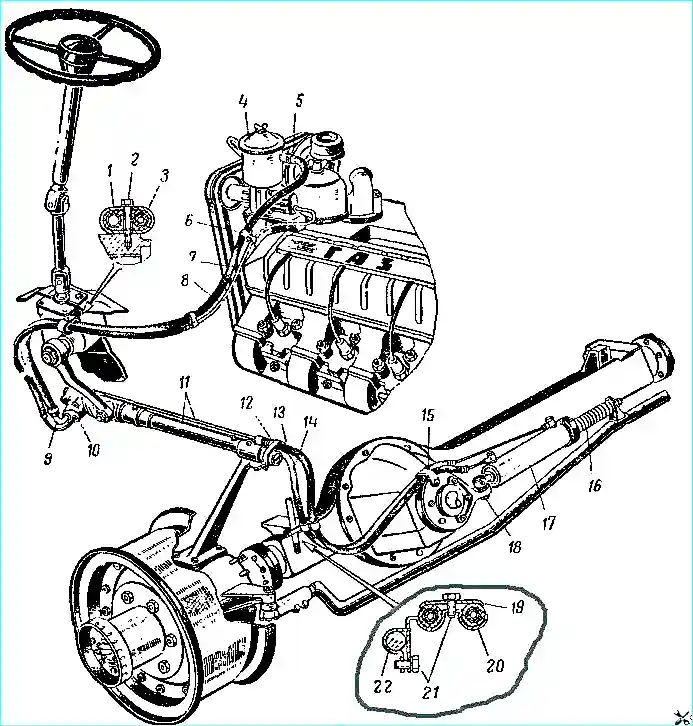

Fig. 1. Power steering: 1 - hose mounting coupling bracket; 2 - bolt; 3 - hose mounting coupling; 4 - pump reservoir; 5 - drain hose clamp; 6 - hose mounting bracket; 7 - drain hose; 8 - discharge hose; 9 - drain hose tip; 10 - control valve; 11 - pipelines; 12 - hose mounting clamp; 13, 14 - hoses to the power cylinder; 15 - hose mounting bracket; 16 - power cylinder rod seal; 17 - power cylinder; 18 - cylinder mounting ball pin; 19 - hose mounting plate; 20 - hose mounting bracket; 21 - bolts; 22 - bracket bracket

An oil tank is installed on the pump.

There is a filler filter under the tank cover, and a mesh filter is installed on the drain hose pipe through which oil returns from the system to the pump.

Two valves are located in the pump cover.

The safety valve (internal) limits the maximum pressure in the system within 65-70 kg/cm² .

The bypass valve limits the amount of oil that is supplied by the pump to the power steering system at high engine crankshaft speeds.

The valve is designed so that no more than 10 l/min of oil is directed to the power steering system.

Excess oil is bypassed inside the pump and goes back to the suction cavities.

The control valve is located at the front end of the longitudinal steering rod.

Inside the valve body there is a spool valve, which is connected through intermediate parts to the steering knuckle pin.

The spool valve is sealed with rubber cuffs at both ends.

When the spool valve is in the middle position (the car is moving straight), the oil entering the control valve through the discharge hose is bypassed through the gaps between the ends of the spool valve necks and the channels in the body into the drain hose and returns to the pump tank.

When the steering wheel is turned, the knuckle pin moves the spool valve, which, by blocking the channels in the valve body, directs oil under pressure into one or another cavity of the power cylinder (depending on which direction the turn is made).

The rod of the power cylinder, connected to the transverse steering rod, moves it, turning the front wheels.

After the turn is completed, the spool valve is set to the middle position, the oil pressure in the power cylinder decreases, and the oil from the valve returns back to the pump without entering the power cylinder.

The double-acting power cylinder is secured in a bracket on the front axle housing via a ball joint.

The piston rod is sealed with two elastic cast iron rings.

The cylinder rod has a chrome coating to increase wear resistance and protect against corrosion.

The rod outlet from the cylinder is sealed with a rubber cuff.

Brass washers and a felt seal are installed on the outside to protect against dirt ingress.

In addition to turning the front wheels, the power cylinder also takes on impacts from the wheels when driving over various uneven surfaces.

This significantly relieves the steering gear and other steering components from impact loads.

Maintenance power steering

The power steering pump drive belts are tensioned by tilting the pump housing. The angle of the pump body should not be too large and should ensure that oil can be poured into the pump tank.

If the tilt of the pump body does not ensure belt tension, move the pump to the holes in the bracket, and if the belts are pulled out too much, move the pump brackets to additional holes in them.

With normal belt tension, the deflection of each belt between the pulleys of the compressor and the power steering pump should be 15-20 mm when pressing the belt with a force of 4 kg.

When checking the oil level in the power steering tank, the front wheels of the car must be installed straight.

Add oil with the engine idling to the "oil level" mark on the wall of the pump tank or, if there is no mark, to the mesh of the inlet filter.

Before removing the tank cap to check the level, top up or change the mit must be thoroughly cleaned of dirt and washed with gasoline.

Pour oil through a funnel with a double mesh and a filler filter installed in the pump tank.

If the filters are significantly clogged with resinous deposits, additionally wash the filters with solvent No. 646, used when painting a car.

During operation, regularly monitor the tightening of the bolts securing the pump and its brackets and the bolts securing the control valve to the longitudinal rod.

Regularly check the tightening of the nut of the ball pin securing the power cylinder to the bracket.

Loosening the tightening of this nut leads to loosening of the ball pin in the conical hole of the bracket.

Periodically check the tightening of the nut of the rod of the power cylinder and the condition of the rubber cushions through which the rod is attached to the rod bracket. When the rubber cushions wear out, they must be replaced.

Oil change

To change the oil, lift the front wheels of the car and open the power steering pump reservoir cap.

To drain the oil, you must:

- - disconnect the pressure and drain hoses from the control valve body and drain the oil from the pump through them;

- - disconnect the hoses from the power cylinder fittings; and drain the oil from them and the control valve;

- - drain the oil from the power cylinder by slowly turning the steering wheel right and left until it stops.

- After draining the oil, flush the power steering system with fresh oil. The filter screens are washed separately.

To add fresh oil, you need to:

- - connect all hoses;

- - pour fresh oil into the tank up to the "oil level" mark and pump the oil at a low number of engine crankshaft revolutions, turning the steering wheel 2-3 times to the stop in both directions without delay in the extreme positions.

While pumping oil, monitor its level in the tank and add oil if necessary. The full capacity of the power steering system is about 1.8 liters of oil;

- - install the tank cap with a sealing gasket, rubber ring of the cap mounting stud and washer and secure with a wing nut.

Tighten the wing nut only by hand. If oil leaks from under the cover, replace the cover gasket.

Driving a car with a non-working power steering

The car's steering allows you to continue driving with a faulty power steering. It should be borne in mind that the effort required to turn the car on the steering wheel will increase.

To continue driving with a faulty power steering, turn off the pump by removing the drive belts.

To reduce the effort on the steering wheel, with a damaged power steering, drain the oil from the power steering system.

If the power cylinder is damaged or faulty, remove it.

Long-term driving with a faulty power steering is not recommended.

Checking the free play of the steering wheel

The free play of the steering wheel is determined by the adjustment of the engagement of the steering mechanism and the design features of the power steering.

When the power steering is not working, the free play of the steering wheel is greater than when it is working. This is a design feature of the power steering.

The maximum allowable free play of the steering wheel with the power steering operating is 60 mm around the steering wheel circumference (or 15°), with the power steering not operating it is 120 mm (or 30°).

Checking the pressure developed by the power steering pump

To ensure that the power steering pump is working properly, it is necessary to measure the oil pressure created by the pump.

To do this, unscrew the discharge hose from the threaded hole of the pump and screw an adapter with a pressure gauge and a tap into this hole.

The pressure gauge must have a scale of at least 80 kg/cm². On the other side, screw the injection hose into the adapter.

To check, open the tap and turn the front wheels of the parked car to the right or left until they stop.

With the wheels in extreme positions, the oil pressure should be at least 60 kg/cm², with the engine crankshaft idling.

If the oil pressure is less than 60 kg/cm², then close the tap on the adapter and monitor the oil pressure on the pressure gauge.

If the pump is working properly, the pressure should rise and be at least 60 kg/cm².

If the pump is faulty, the pressure does not increase. If the pressure increases to 60 kg/cm², then the fault should be looked for in the control valve or power cylinder.

When checking, do not keep the tap closed or the car wheels in extreme positions for more than 15 seconds, as this can lead to overheating and scoring of the pump parts.

The oil in the pump tank should be warm during checking.

Power steering faults and how to fix them

- Causes of fault

Remedies

Insufficient or uneven power assist when turning the steering wheel in both directions:

- Insufficient tension of the pump drive belts

Tighten the belts

-Low oil level in the pump reservoir

Add oil

- Air or water in the system (foam in the reservoir, cloudy oil)

Bleed the air. If the air is not removed, check the tightness of all connections, remove and wash the mesh filter, check the integrity of the gasket under the manifold and the tightness of its mounting bolts. Change the oil if necessary

- Pump malfunction

Check the pump

- Control valve spool jam

Disassemble and wash the control valve

- Power cylinder rod or piston jam

Find out the cause and location of the jam. Repair or replace damaged parts

- Increased oil leakage through the sealing rings in the power cylinder due to their wear or breakage

Disassemble the cylinder and replace the rings

- Periodic freezing of the pump bypass valve due to contamination

Disassemble the pump, check the free movement of the valve

Lack of power when turning the steering wheel to the right:

- The bolt securing the control valve spool has come loose

Tighten the bolt

Complete lack of power at various engine crankshaft speeds:

- Unscrewing the seat of the pump safety valve

Disassemble the pump, tighten the seat

- Jamming of the pump bypass valve

Disassemble the pump, clean and flush from dirt.

If heavily contaminated, flush the entire power steering system

Increased noise during pump operation:

- Insufficient oil level in the pump reservoir

Add oil

- Insufficient tension of the pump drive belts

Tighten the belts

- Clogged or incorrectly installed filter

Flush the filter, install it correctly

- Air in the system

Remove air

- Deformation of the manifold plane in the pump reservoir

Straighten or replace the manifold

- Severe wear and tear of pump parts

Disassemble and check the pump parts, replace if necessary

Knocking in the front of the pump:

- Severe wear of the ball pump shaft bearing

Replace bearing

Oil leaking through breather:

- Oil level above mark

Set normal level

- Mesh filter clogged

Flush filter

- Manifold gasket damaged

Replace gasket

- Manifold bent

Straighten or replace manifold