Removal and installation of the camshaft of the ZMZ-402 engine

Remove the fan drive belt.

Remove the generator drive belt.

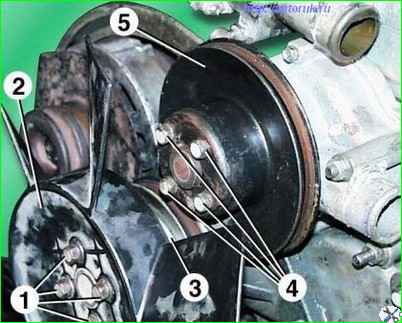

Unscrew four bolts 1, remove fan 2 and fan pulley 3.

Unscrew four bolts 4 and remove pulley 5 of the water pump.

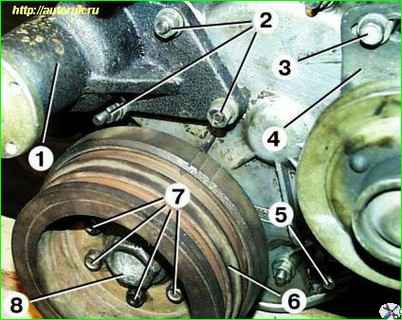

Unscrew the three nuts 2 and remove the fan drive 1.

Unscrew bolt 3 and nut 5, remove bracket 4 with tension roller.

Unscrew the six bolts 7 and remove the crankshaft pulley 6 with the torsional vibration damper assembly.

Unscrew the coupling bolt 8 (or ratchet) with a puller, remove the crankshaft pulley hub.

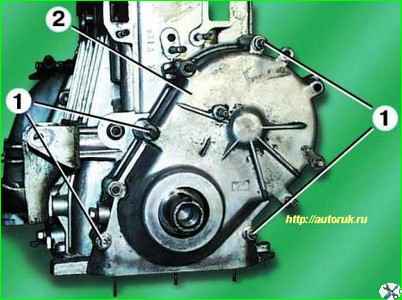

Unscrew the remaining nuts 1 and remove the cover 2 of the timing sprockets.

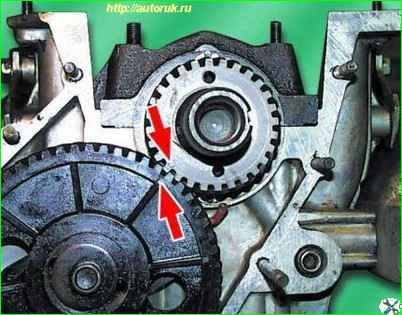

Install the piston of the 1st cylinder in the idle position. compression stroke.

To do this, turn the crankshaft so that the marks on the crankshaft sprocket and the camshaft gear align.

Remove the ignition distributor drive.

Remove the oil filter.

Remove the fuel pump.

Remove the rocker cover.

Remove the valve rocker arm axle with the struts assemblies.

Remove the pusher rods, having previously marked them with the valve number.

Unscrew nuts 1 and remove cover 2 of pushers together with the gasket.

Remove pushers 1.

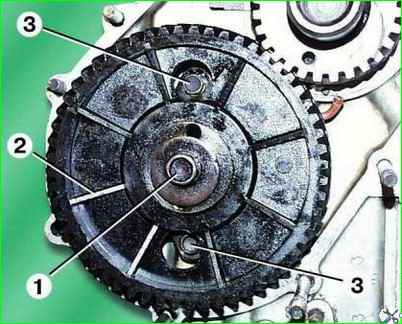

Unscrew bolt 1 and remove camshaft gear 2 using a puller.

Unscrew bolts 3 and remove the camshaft thrust flange with spacer

Carefully remove the camshaft from the cylinder block.

Inspect the camshaft

After removal, wash all parts with gasoline, wipe and dry.

Inspect the camshaft. If there are burrs, deep scratches, holes, chips, cracks on the journals, cams and gear of the oil pump drive, replace the camshaft.

Measure the diameters of the camshaft journals

Inspect the push rods. Replace bent rods. If signs of wear are noticeable on the tips of the rods, burrs, shells, also replace the rods.

It should be noted that the length of the motor rod mod. 402 is equal to 283 mm, and the engine mod. 4021 - 287 mm.

Inspect the pushers. If the working surfaces show signs of wear, pitting, scuffing, etc., replace the pushers.

If the camshaft gear has damaged teeth or cracks, it must be replaced.

Measure the axial clearance of the camshaft.

To do this, assemble the shaft with the gear, put a spacer ring and a thrust flange on the front end of the camshaft, then press on the gear and tighten the gear bolt with the washer.

Tighten the bolt to a torque of 55–60 Nm (5.5–6.0 kgf m).

Use a feeler gauge to measure the gap between the camshaft thrust flange and the gear hub; it should be within 0.1–0.2 mm.

Installing the camshaft

Install the camshaft in the reverse order of removal.

Before installation, lubricate the camshaft journals and cams, tappets and tappet rods with engine oil.

After installation, adjust the clearances in the valve drive.