Compression (pressure at the end of the compression stroke) in the cylinders is the most important indicator for diagnosing the condition of the engine without disassembling it

By the average compression value and the difference in values in individual cylinders, it is possible to determine with a sufficient degree of accuracy the degree of general wear of parts of the connecting rod and piston group of the engine, and identify malfunctions of this group and parts of the valve mechanism.

They check compression with a special device, a compression meter, which can currently be freely purchased at large auto parts stores.

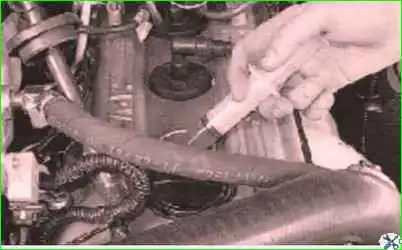

There are options for compression meters that have a rubber tip instead of a threaded fitting for screwing in instead of a spark plug.

When checking compression, such compression gauges are simply pressed firmly against the spark plug hole.

Important conditions for correct readings when checking compression are the serviceability of the starter and its electrical circuits, as well as the full charge of the battery.

You will need a 21mm socket wrench to remove the spark plugs.

Start the engine and warm it up to operating temperature.

Stop the engine, disconnect the low-voltage wiring harness connector from the ignition module.

Warning. Cranking the engine with the starter while the tips of the high-voltage wires are disconnected and the ignition module is not disconnected can lead to breakdown of its high-voltage circuit.

Turn out all the spark plugs.

Disconnect the fuel pump by removing the wire block from the fuel pump relay terminals.

Screw the compression gauge into the spark plug hole of the cylinder being tested.

Press the accelerator pedal fully to fully open the throttle.

Turn on the starter and turn the engine crankshaft until the pressure in the cylinder stops increasing. This corresponds to approximately four compression cycles.

After recording the compression gauge readings, set its needle to zero by pressing the air release valve.

Note. For compression meters of a different design, readings can be reset in other ways (in accordance with the instructions for the device).

Repeat these operations for the remaining cylinders. the pressure must not be lower than 660 kPa (6.65 kgf/cm²) and should not differ in different cylinders by more than 98 kPa (1 kgf/cm²).

Reduced compression in individual cylinders can result from loose valve seats, damaged cylinder head gaskets, broken or burned piston rings.

Reduced compression in all cylinders indicates wear of the piston rings.

To find out the reasons for insufficient compression, pour about 20 cm³ of clean engine oil into the cylinder with reduced compression and measure the compression again.

If the compression gauge readings have increased, the piston rings are most likely faulty.

If the compression remains unchanged, this indicates a loose fit of the valve plates to their seats or damage to the cylinder head gasket.

Helpful advice. The cause of insufficient compression can be determined by supplying compressed air to the cylinder, in which the piston is pre-installed at TDC of the compression stroke.

To do this, remove the tip from the compression gauge and attach the compressor hose to it.

Insert the tip into the spark plug hole and supply air to the cylinder at a pressure of 200-300 kPa.

To prevent the engine crankshaft from turning, engage the highest gear and brake the car with the parking brake.

Air output (leakage) through the throttle assembly indicates a leak in the intake valve, and through the muffler indicates a leak in the exhaust valve.

If the cylinder head gasket is damaged, air will escape through the throat around the expansion tank in the form of bubbles or into an adjacent cylinder, which is detected by a characteristic hissing sound.

When the compression rings wear out, air will escape through the oil dipstick.