At the engine mod. 406 the oil pump is driven by an intermediate shaft, for engine mod. 402 the pump and ignition distributor are driven by the camshaft

Remove the timing gear drive, article "Shaft drive ZMZ-406"

We remove the intake pipeline if we did not remove the cylinder head, the article "How to remove the intake pipes and exhaust manifold of the ZMZ-406 engine"

Using the “12” key, unscrew the two bolts securing the intermediate shaft flange and remove the flange.

Using the “12” key, unscrew the four bolts securing the drive cover and remove it, being careful not to damage the gasket.

We take out the driven gear of the drive.

We wrap two bolts (M8) into the threaded holes of the end of the intermediate shaft.

Using the “12” key, unscrew the nut securing the intermediate shaft gear, rotating the shaft with a screwdriver inserted between the bolts.

We remove the intermediate shaft, its gear and the hexagonal drive shaft from the block.

We assemble the drive in reverse order.

In this case, we recommend installing the hexagonal drive shaft last.

On the ZMZ-402 engine

At the engine mod. 402 remove the ignition distributor.

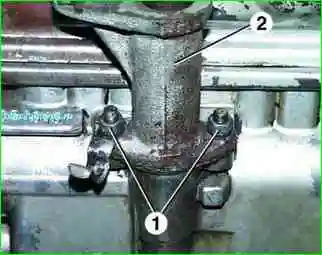

Unscrew the two nuts 1 and pull the drive 2 upwards.

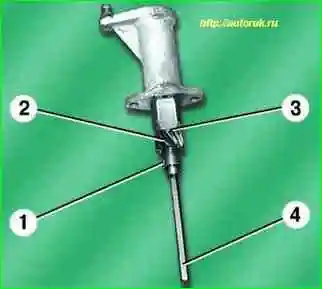

Press out the pin 1 of the drive gear and remove the hexagonal shaft 4 of the oil pump drive.

Then compress gear 2 of the drive, while applying force to the roller through a mandrel with a diameter of 12 mm.

Remove bronze thrust washer 3.

Installation

Assembly and installation of the drive is carried out in the reverse order.

When assembling the actuator mod. 402, it is necessary to provide a gap between the end face of the drive gear and the bronze thrust washer within 0.15–0.4 mm.

Rivet the pin on both sides.