The safety valve is designed to protect the pneumatic system from excessive pressure increase in the event of damage to the automatic pressure regulator

The valve is installed on the front right cylinder.

The safety valve is adjusted so that it opens when the air pressure in the pneumatic system reaches 9-9.5 kg/cm 2.

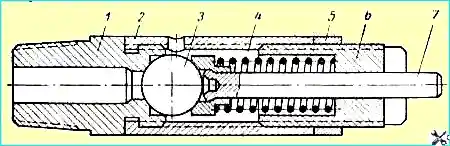

The valve is adjusted to the specified pressure with screw 6, which is locked with lock nut 5.

It is necessary to periodically check the tightness of the valve using a soap emulsion; to eliminate increased air leakage, the valve should be disassembled, washed in gasoline or kerosene and dried.

The working belt of the seat and the ball should not have scratches or other surface damage.

During maintenance, it is necessary to check the proper operation of the safety valve of the pneumatic brake drive system.

To do this, pull the valve rod - the valve should release air.

Then release the rod; if in this case the air stops releasing, the valve is working normally.