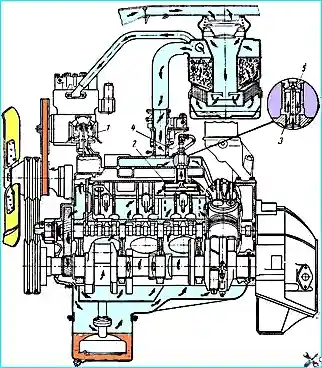

Crankcase ventilation is forced, by sucking crankcase gases into the engine intake manifold through a special valve 3 installed on the intake manifold

Gases are sucked out of the valve through a special tube into the central part of the intake manifold.

Tap 4 is installed between the tubes to turn off the ventilation system when fording.

The tap handle must be positioned vertically when fording.

After fording, the handle must be turned to a horizontal position.

When the engine is running with the throttle valve slightly open, under the action of a large vacuum in the intake manifold, valve 3 rises, the upper stepped part of the valve enters the hole of nipple 5 and reduces the flow area of the valve to the value necessary for the passage of a small volume of gases breaking through into the engine crankcase.

When the engine is running with the throttle valve fully open, the vacuum in the intake manifold drops, and the valve, under the action of its own weight, drops, completely opening the flow area, the size of which corresponds to the passage of a large volume of gases breaking through into the engine crankcase.

During maintenance, it is necessary to clean the valve using acetone or another similar solvent.

Before the valve, at the outlet from the internal space of the engine, crankcase gases pass through a special trap 2, which separates oil particles from the sucked-out gases.

Outside air enters the engine crankcase through air filter 1, combined with the oil filler neck.

This filter is cleaned and washed every time the engine oil is changed.