The pressure regulator is installed on the compressor cylinder block. To increase the reliability of the pressure regulator, it is equipped with two filters:

- one filter 8 is installed where air enters from the pneumatic system, the other filter 7 is installed where air enters the regulator from the compressor unloader.

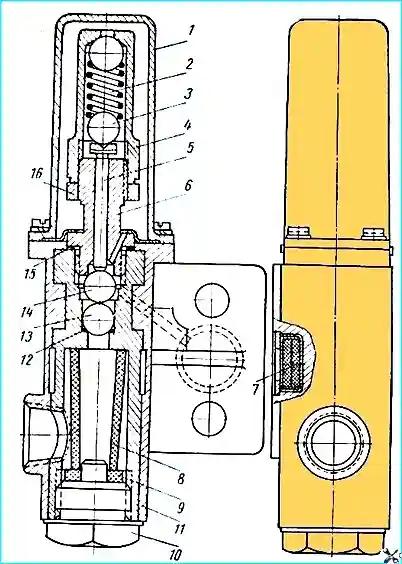

Pressure regulator: 1 - casing; 2 - regulator spring; 3 - thrust ball; 4 - adjusting cap; 5 - valve stem; 6 - pressure regulator outlet valve seat; 7 - mesh filter; 8 metal-ceramic filter; 9 - sealing ring; 10 - pressure regulator housing; 11 - filter plug; 12 - valve spring; 13 - inlet valve; 14 - outlet valve; 15 - adjusting linings; 16 - regulating valve lock nut

The pressure regulator automatically maintains the required compressed air pressure in the system by admitting air into the compressor unloader or releasing air from it.

When the pressure in the pneumatic system reaches 7.0-7.4 kg/cm 2 the regulator turns off the air supply to the compressor, and when the pressure drops to 5.6-6.0 kg/cm 2 turns the compressor on again.

If the pressure in the pneumatic system is not maintained within the specified limits, then it is necessary to determine the cause of the malfunction and eliminate it.

The reason for the violation of the pressure limits in the pneumatic system may be a malfunction of the pressure regulator or wear of the sealing rings of the plunger of the unloader, so it is necessary to first check the tightness of the plungers of the unloader.

If and after eliminating the leak plungers pressure limits do not correspond to the norm, then you should disassemble the regulator, wash the parts in gasoline or kerosene and dry.

Only qualified personnel are allowed to open and adjust the pressure regulator.

It is recommended to check the pressure regulator on a special stand.

Damage to the surface of the balls and their seats is unacceptable.

Adjust the regulator in the following sequence.

1. By rotating the cap 4, ensure that the compressor starts working at a pressure of 5.6-6.0 kg / cm 2.

When the cap is screwed on, the pressure increases, when unscrewed, it decreases.

Secure the cap with lock nut 16.

2. By changing the number of gaskets 15, we obtain a pressure of 7.0-7.4 kg/cm 2, at which the compressor switches off.

With an increase in the number of gaskets, the pressure decreases, with a decrease, it increases.