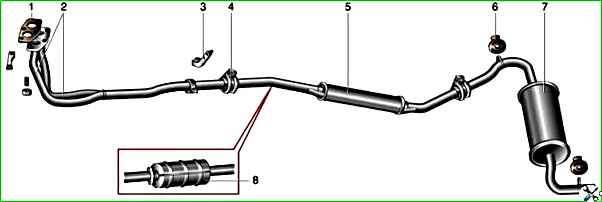

The exhaust system of the VAZ-21213 and VAZ-21214 consists of an exhaust manifold, a reception pipe, an additional and main muffler

On vehicles with an injection system, an exhaust gas converter is installed between the exhaust pipe and the additional muffler.

On these cars, a threaded bushing for the oxygen concentration sensor (lambda probe) is welded into the exhaust pipe (immediately after the transition of two thin pipes into one).

The additional muffler is also different - its front pipe is shorter and equipped with a flange for attaching the neutralizer.

Mufflers and neutralizer are non-separable units and must be replaced with new ones when they fail.

The exhaust manifold is cast from cast iron.

A metal-reinforced heat-resistant gasket is installed between it and the cylinder head.

The exhaust pipe is attached to the manifold on four studs.

The connection is sealed with a heat-resistant gasket.

The fastening nuts are brass or copper-plated and are secured against unscrewing by locking plates (one per two nuts), the edges of which are bent at the edge of the nuts.

The exhaust pipe is additionally attached with a clamp to the bracket on the gearbox.

On cars with carburetor engines, the muffler pipes are pushed into each other and secured with crimp clamps.

On vehicles equipped with an injection system, the connections of the converter with the additional muffler and the exhaust pipe are flanged, the front one is with a ball joint (the pipes can be rotated relative to each other at a small angle without loss of tightness), its mounting bolts are spring-loaded.

The neutralizer is used to reduce emissions of carbon monoxide and nitrogen oxides into the atmosphere.

It consists of two ceramic blocks with many pores, coated with so-called afterburning catalysts: rhodium, palladium, platinum.

Passing through the pores of the neutralizer, toxic carbon monoxide (CO) is converted into low-toxic dioxide (CO 2), and nitrogen oxides are reduced to harmless nitrogen.

The degree of gas purification in a working neutralizer reaches 90–95%.

For normal operation of the converter, the composition of the exhaust gases (in particular, the oxygen content in them) must be within strictly specified limits.

This function is performed by the controller, changing the amount of fuel supplied depending on the readings of the oxygen sensor.

The neutralizer and oxygen sensor are very sensitive to lead compounds - if they are “poisoned” by them, they stop working.

Therefore, if a car is equipped with a neutralizer, its operation (even short-term) on leaded gasoline is strictly prohibited.

Another reason for the failure of the neutralizer is interruptions in the ignition system: unburned fuel burns out in the neutralizer, damaging the ceramics.

This may cause the exhaust system to become clogged and the engine to stop (or severely lose power).

The main muffler is located in a niche at the rear of the body.

It is attached to the body brackets on two rubber pads.

The middle part of the exhaust system (with an additional muffler) does not have attachment points to the body.

To protect the body floor from excessive heating, a protective screen is attached above the main muffler.

Maintenance of the exhaust system consists of periodically inspecting pipes and mufflers for corrosion and tightening or replacing loose connections.