Replacement of springs is required when spring leaves settle or break

The vehicle can be equipped with three-leaf springs with single-leaf additional springs or five-leaf springs with three-leaf additional springs

Three-leaf springs have plastic spacers between the leaves.

The front end of the spring is attached through a rubber-metal hinge to a bracket on the frame, and the rear end is attached to a shackle.

The spring is attached to the rear axle using stepladders.

A plastic gasket is installed between the main and additional springs.

You will need: a 22mm wrench, a 24mm socket, a hammer, a bit, a drift.

Loosen the four nuts securing the stepladders

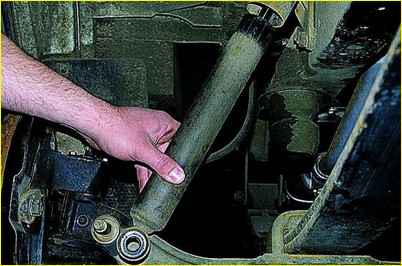

Disconnect the lower shock absorber mount; to do this, use a 19 mm socket to unscrew the nut of the lower shock absorber mount

Remove the washer

Disconnect the lower part of the shock absorber

Unload the spring by lifting the rear of the car and install a support under the rear of the frame.

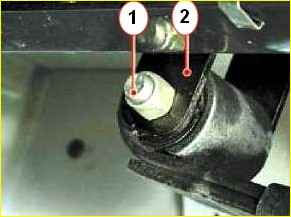

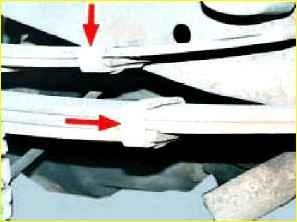

Unscrew the nut of pin 1 securing the front end of the spring to the bracket on the frame so that it remains flush on pin 1, generously moisten the hinge and pin with soapy water or brake fluid and, using a drift, knock out the pin through the mounting hole in the frame until it touches the bracket nut 2.

Unscrew the nut and finally knock out pin 1 using a bit, applying force to the end of the pin.

Together with your finger, remove two spring washers and one thrust washer.

Unscrew the nut of pin 1 securing the rear end of the spring to shackle 2.

Wet the joint and pin 1 generously with soapy water or brake fluid.

Knock out the lower pin 2 without damaging the thread.

Using a jack, lift the rear of the car by the frame so that the ends of the spring come out of the bracket and the earring

Unscrew the four nuts of the spring ladders.

Remove stepladders

Remove the cover

Remove the spring.

Remove the rubber-metal hinges from the spring lugs.

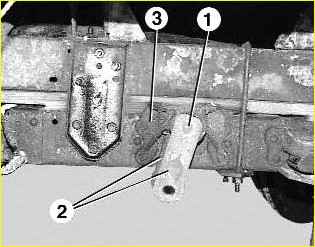

If it is necessary to replace the rubber-metal hinge of the earring, unscrew the nut of pin 1 of the fastening, knock out the upper pin 1, remove the cheeks of 2 earrings and remove hinge 3 from the bracket

Clean the spring from dirt. Clean the spring lugs from rust.

Be sure to replace the spring hinges.

Inspect your fingers. They should not have visible signs of wear, deformation, rust, or dirt. The threaded part of the pins must not be damaged.

The spring shackles and the front pin washer must not be deformed.

Inspect the springs. The spring leaves must not have cracks. If these defects are found, replace the spring assembly or, after disassembling the spring, replace the defective sheets.

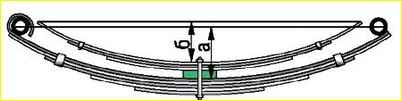

Check the spring deflection in the free state.

To do this, stretch a thin rope or wire between the centers of the spring eye holes and measure the distance “a” from the top surface of the first sheet at the central bolt to the stretched rope.

For three-leaf springs, the measured distance “a” should be 140–160 mm, and for five-leaf springs - 130–140 mm.

The difference in deflection of both rear springs should be no more than 10 mm.

To check the deflection of the additional spring, stretch a thin rope or wire between the ends of the top leaf of the spring and measure the distance “b” from the top surface of the first leaf at the central bolt to the stretched rope.

For single-leaf springs, the measured distance “b” should be 111–121 mm, for three-leaf springs – 76–86 mm.

The difference in deflection of both additional springs should be no more than 10 mm.

Install the spring in the reverse order of removal.

To make it easier to press in rubber-metal hinges, lubricate them with a thick soap solution.

When installing, please note that the short end of the spring should be directed forward in the direction of travel of the vehicle.

Finally tighten the threaded connections of the spring mounting with the car standing on the ground to a torque of 120–150 Nm (12–15 kgcm).

Tighten the two nuts of the earring pins evenly to avoid distortions.

Disassembly and assembly of the rear spring

You will need: a 17" wrench, a hammer.

Mark the orientation of the sheets in the spring.

Clamp the spring in a vice as close to the center bolt as possible.

Unbend and remove the tie clamps from the main and additional springs.

Unscrew the center bolt nut and remove the center bolt.

Slowly open the vice to gradually remove the load from the spring.

Assemble the spring in the reverse order of disassembly, having previously lubricated the sheets of a five-leaf spring with graphite lubricant (on three-leaf springs, plastic spacers are installed between the sheets).

Install a plastic spacer between the main and additional springs.

In this case, center the holes in the sheets of the main and additional springs using a metal rod, and then, after compressing the entire package, replace the rod with a center bolt.

The head of the bolt should be at the bottom of the spring.

If the springs “sag”

If the rear suspension springs have sagged and there are no new ones, you should not straighten the sheets with rollers, a press or a sledgehammer, or install additional sheets from Volga, UAZ and other cars.

It is much better to make and install earring plates extended by 30–40 mm. The car will rise noticeably and the old springs will still serve.