The power steering pump is removed for replacement or repair

Emerging defects in the hydraulic steering pump:

- - wear of pump bearings (constant noise from the pump);

- - the flow and safety valve do not work due to contamination (high pressure occurs in the system);

- - liquid flow through the technological holes in the pump housing (the plugs have been squeezed out);

- - fluid leaking from under the pump covers.

If the steering wheel turns hard in both directions, the pump is faulty.

Pumps can be supplied as spare parts with hose fittings or without fittings.

Removing the pump

Raise and place the front part of the car on supports.

Remove the engine splash guard

Drain the fluid from the power steering system, see the article - Changing the oil in the GAZ-2705 power steering

Remove the accessory drive belt, see the article - Replacing the accessory drive belt

Loosen the clamp on the upper pump hose

Disconnect the upper hose

Unscrew the nut of the lower hose mounting fitting, holding the nut with a second wrench

Move the hose away from the pump.

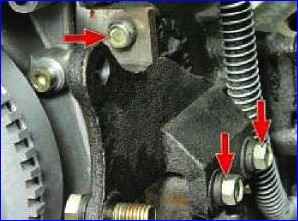

Remove the two pump mounting bolts

Removing the pump

If you need to remove the bracket, then unscrew the three bolts that secure it

Remove the bracket

Install the pump and all removed parts in the reverse order

After installation, fill the system with hydraulic fluid and bleed the system.

Washing the flow and safety valves of the power steering pump

We clean the outside of the pump from dirt.

Use a 24mm wrench to unscrew the plug located above the pump outlet. (For clarity, shown with the pump removed.)

Remove the flow valve spring.

Remove the spool

To prevent oil from leaking out and dirt from getting inside the pump, we install the plug in place

Use a thin screwdriver to carefully remove the rubber seal from the spool.

Having wrapped the spool body in thin cardboard or a piece of emery cloth, and carefully holding it in a vice, use a 10mm wrench to unscrew the spool seat.

When releasing the spool body from the vice, hold it vertically so as not to lose small parts of the valve.

Remove the ball, guide rod and spring from the spool body

We wash all parts in gasoline and blow with compressed air (from a pump or compressor).

Assemble the spool and install it in place in the reverse order.