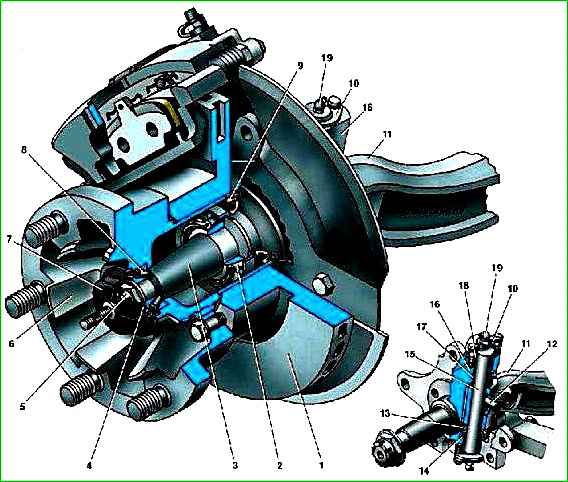

The front wheel hubs rotate on two tapered roller bearings 2 and 8 mounted on the steering knuckle

The outer rings of the bearing are pressed into the hub, and the inner rings are installed freely on the fist

Six bolts are pressed into the hub flange to secure the wheels.

The brake disc is also installed on the flanges.

Front wheel hubs require periodic bearing adjustment and lubricant changes in accordance with the owner's manual.

Adjusting the front hub bearings

To adjust, do the following:

- lift the wheel with a jack so that the tire does not touch the support plane, remove the wheel cap, remove the hub cap 7, undo the cotter pin and loosen the adjusting nut 5 by ½ turn, check the ease of rotation of the wheel

In case of wheel braking, eliminate the cause;

- tighten the adjusting nut 5 with a wrench with a torque of 50-80 Nm (5.0-8.0 kgcm).

When tightening the nut, it is necessary to rotate the wheel to evenly place the rollers in the bearings;

- - unscrew nut 5 to an angle of 22-45° (no more than one slot in the crown) and secure it with a cotter pin;

- - make sure the wheel bearings are adjusted correctly - the wheel should rotate freely without axial play;

- - put the hub and wheel caps in place;

- - finally check the correctness of the bearing adjustment after a run of 8-10 km.

Strong heating of the hub (over 70° C) is unacceptable and must be eliminated by repeated adjustment.

The lubricant should be replaced on the removed hub after 36,000-60,000 km, depending on operating conditions, for this you need:

- - remove the decorative and inner 7 hub caps

- - loosen the wheel nuts, then jack up the car wheel, remove the wheel;

- - unscrew the steering knuckle nut and unscrew it;

- - remove the hub, wash it and the bearings in kerosene, after removing the old grease;

- - lubricate the bearings and fill the inner cavity of the hub with Litol-24 or Lita grease in the amount of 75 g per hub;

- - install the hub, tighten the nut, adjust the bearings (as indicated above), tighten the nut, install the inner cap, wheel, pre-tighten the wheel nut;

- - lower the wheel from the jack. Finally tighten the wheel nuts to a torque of 300-380 Nm (30-38 kgf);

- - install a protective cap.

When replacing the oil seal, you must perform the steps for removing the hub given above.

The oil seal should be pressed evenly into the hub.

After pressing, its back side should be in the same plane with the end of the hub.