To eliminate a specific malfunction, as a rule, only partial disassembly of the carburetor is required; in this case, individual operations can be skipped

Remove the air filter housing (see Removing the air filter housing).

Remove the solenoid valve, fuel filter, disconnect the limit switch connector (see Removing and checking the solenoid valve)

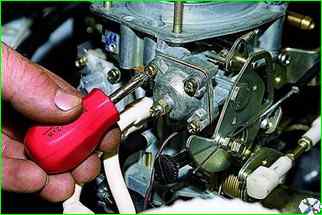

Using a Phillips screwdriver, loosen the clamp of the fuel return drain hose and remove the hose from the carburetor fitting.

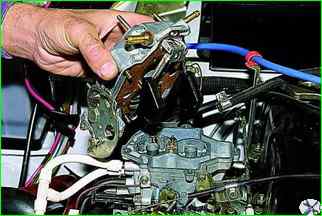

Use a Phillips screwdriver to unscrew the four screws securing the starter cover

Pulling out the air damper control handle, remove the cover with the diaphragm and rod, turning it slightly so that the curved end of the rod passes through the groove of the starter housing.

Carefully separating the diaphragm from the body, remove it and the spring located under it.

When installing the cover, align the hole on its mating plane with the hole on the edge of the diaphragm (shown by arrows) and the adapter sleeve of the vacuum supply channel on the starting device body.

Holding the air damper cable mounting sleeve on the three-arm lever with an 8 wrench, use another 8 wrench to loosen the cable fastening bolt without turning it out.

Slightly pull out the choke control handle so that the cable comes out of the bushing.

Use a Phillips screwdriver to unscrew the five screws securing the cover (four of them are in the wells)

Remove it (don’t lose the screws!). Subsequent disassembly of the cover is described at the end of the article

Remove the rubber sealing ring from the adapter sleeve of the idle speed system

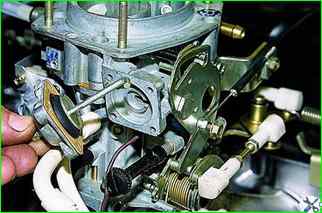

Use a slotted screwdriver to unscrew the main air jets with emulsion tubes and remove them.

Use a slotted screwdriver with a 4 mm wide blade to remove the main fuel jets.

With the carburetor removed, the main fuel jets can simply be shaken out of the wells by turning the body over.

If karburetor on the car, it is convenient to use a sharpened stick or a long screw.

Use pliers to remove small diffusers.

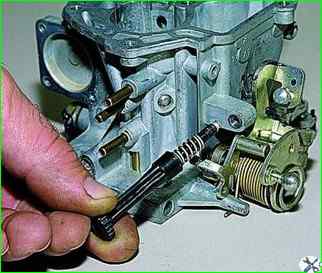

Using pliers with thin jaws, remove the accelerator pump nozzle along with the rubber sealing ring.

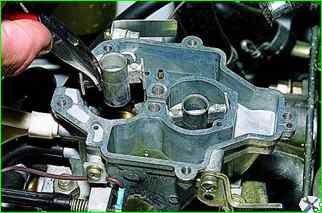

Use a Phillips screwdriver to unscrew the four screws securing the accelerator pump cover and remove it along with the diaphragm and spring.

Remove the spring and carefully separate the diaphragm.

Use a Phillips screwdriver to unscrew the three screws securing the power mode economizer cover

Remove the cover, spring and diaphragm

Use a slotted screwdriver to unscrew the economizer nozzle.

Further operations are shown with the carburetor removed for clarity.

Use a Phillips screwdriver to unscrew the screw of the plastic holder for the limit switch wire and disconnect the wire from the limit switch.

Turn out the adjusting screw for the amount of idle mixture with the spring.

Use a narrow slotted screwdriver to unscrew the mixture quality adjustment screw and remove it together with the rubber sealing ring.

Sometimes this requires drilling out the edge of the carburetor body and using a wire hook.

Disassembling the carburetor cover

Use a drift with a diameter of 2.5 mm and use a hammer to knock out the float axis.

Remove the axle and floats.

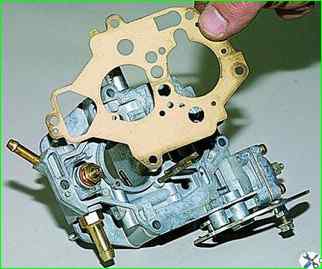

Remove the cover gasket. (Caution, the cardboard peels off easily!)

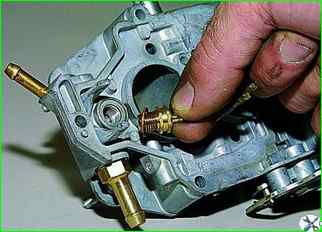

Use the “11” key to turn out the needle valve.

Take out the needle valve and the copper O-ring.

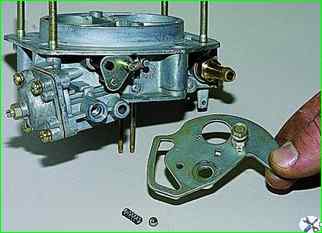

Using a 14mm wrench, unscrew the fastening bolt (axis) of the air damper control lever and, having removed the lever, remove the ball and spring located underneath it. (Be careful, the ball is easy to lose!)

Assemble the carburetor in reverse order