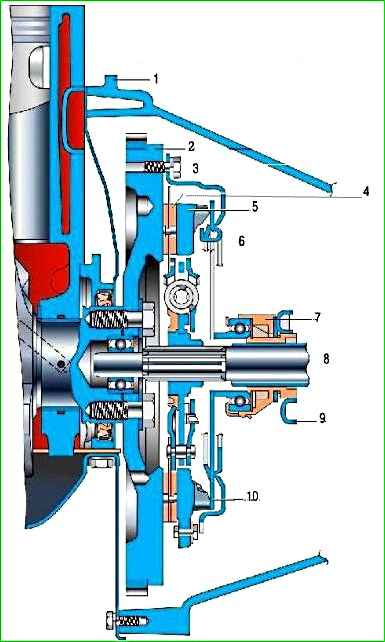

The vehicle is equipped with a single-plate, dry, permanently closed clutch with a central diaphragm spring

The clutch device is shown in Fig. 1

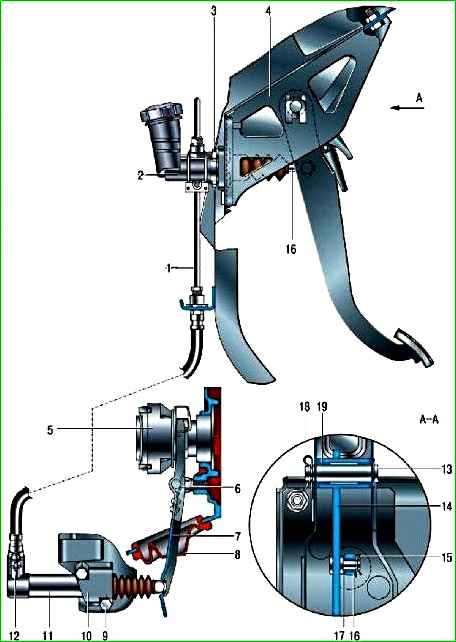

The clutch drive is hydraulic, backlash-free, with automatic wear compensation of the friction linings of the driven disk.

The drive consists of the master 2 (Fig. 2) and slave 11 cylinders, the clutch pedal, the tube 1 of the clutch release hydraulic drive and a hose.

To ensure that the clutch serves you for a long time and without failure, do not keep your foot on the clutch pedal all the time.

This bad habit is often acquired during driving lessons at driving schools out of fear of not having time to disengage the clutch when the car stops.

In addition to the rapid fatigue of the foot, which is always above the pedal, the clutch is at least slightly squeezed, and the driven disk slips and wears out.

In addition, although the release bearing is designed to operate in the constant rotation mode, when the pedal is pressed slightly, it is under increased load, and its service life is reduced.

For the same reason, we do not recommend keeping the clutch in the disengaged state for a long time (for example, in traffic jams).

If you do not have to move off immediately from a standstill, it is better to engage the neutral position of the gearbox and release the pedal.

Clutch slippage can be easily determined using a tachometer.

If, while driving, when you press the accelerator pedal sharply, the revs increase sharply and then drop a little and the car begins to accelerate, the clutch requires repair.

Checking the technical condition of the clutch

Check the technical condition of the clutch in the following ways.

Engage the neutral gear in the gearbox, start the car engine and warm it up to operating temperature.

When the engine is running at minimum crankshaft speed, disengage the clutch (press the pedal) and engage reverse gear.

The gear should engage without grinding, knocking or other extraneous noises.

Shift gears while the car is moving. All gears should engage without grinding, knocking or other extraneous noises.

When accelerating the car, there should be proportionality between the increase in engine speed and the increase in vehicle speed (the clutch should not "slip").

Clutch slippage can be easily determined using a tachometer.

If, while driving, when you sharply press the accelerator pedal, the speed increases sharply and then drops slightly and the car begins to accelerate, the clutch requires repair.

If the above signs of normal clutch operation are absent, try bleeding the air from the clutch hydraulic drive, article - "How to bleed the clutch"

If bleeding the hydraulic drive does not lead to the desired result, remove the clutch for repair.