After repairing engine assemblies or replacing them, run the engine on a stand equipped in accordance with the requirements of GOST 14846-81, in one of the modes below, depending on the replaced parts:

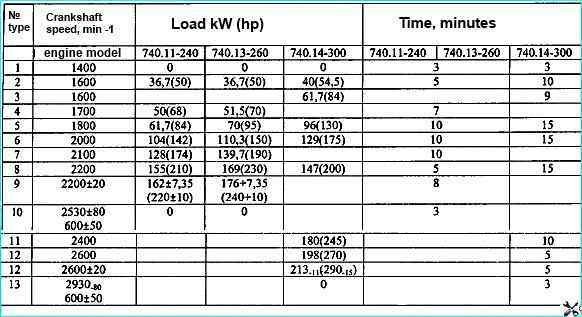

1. After replacing the crankshaft, camshaft, one or more pistons or liners, more than half of the main or connecting rod bearing shells, and more than two piston rings, run in the main mode, which includes "cold" and "hot" running-in (Tables 1, 2).

Table 1

Crankshaft speed, min -1 – time, minutes

- 600 – 2 minutes

- 800 – 3 minutes

- 1000 – 5 minutes

- 1200 – 5 minutes

- 1400 – 5 minutes

At the beginning of the "cold" running-in, the temperature of the oil supplied to the engine is allowed to be 50 °C and above.

The oil pressure in the main line of the lubrication system is not lower than 98.07 kPa (1 kgf/cm 2) at minimum idle speed and 392.3 - 539.4 kPa (4 -5 kgf/cm 2) - at nominal speed

Before the "hot" running-in, check and, if necessary, adjust the thermal clearances in the valve timing mechanism, fuel injection advance angle, tightening of cylinder head mounting bolts.

Water and fuel leakage and leakage, as well as gas breakthrough at joints are not allowed.

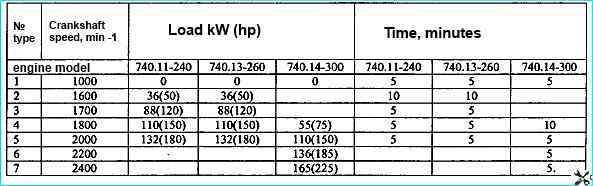

- 2. After replacing less than half of the main or connecting rod bearing liners or one piston ring in no more than two cylinders, run-in the engine in the "hot" running-in mode.

- 3. After replacing the cylinder head or other parts, the replacement of which requires removing the head, after removing it for inspection of the cylinder-piston group parts, as well as replacing the oil, liquid or fuel pumps, fuel pump drive, timing gears, crankshaft seals, flywheel housing, front block cover, run-in the engine in the mode specified in the table. 3.

- 4. After overhaul without replacing units, assemblies, or parts, run-in the engine in the mode according to paragraph 3.

The engine run-in should always be completed on the vehicle, observing the recommended driving speeds specified in the "Vehicle Operating Manual" attached to the vehicle.

Run-in of a new or repaired engine in the vehicle for 1000 km is mandatory.

Run-in is necessary to ensure the running-in of the rubbing surfaces of the parts, and therefore the engine should not be loaded at full power during this period.

The load must be increased gradually so that by the end of the run-in period it does not exceed 75% of the operating power.

After preparing the engine, start it and warm it up. After making sure that the engine is working properly, start running-in.

When running-in, use the vehicle for light work.

Recommendations for choosing running-in modes should be set out in the vehicle operating instructions.

During operation, monitor the engine condition using the control instruments.

Prolonged operation (more than 15 minutes) of an unrun-in engine in idle mode is not allowed when the coolant temperature in the system is below 75 °C.

After 1000 km of mileage, perform maintenance TO-1000.