During operation, it is necessary to periodically check the tightness of the riveted joints of the frame by tapping the heads of the rivets with a hammer, to prevent cracks in the flanges of the side members and cross members

Make sure that the geometry of the frame (the correct position of the spars, crossbars and frame brackets) and its paintwork are not violated: corrosion damage must be removed, and places with damaged coatings should be tinted.

Periodically retighten the nuts of the coupling bolts securing the subframe to the frame of the dump truck and other bolts on the subframe.

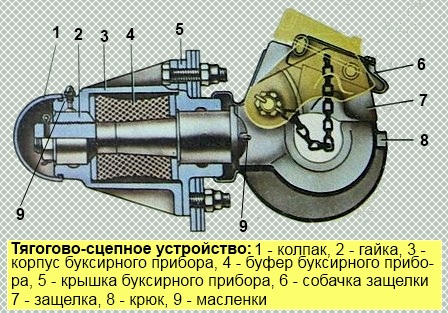

During daily maintenance, visually check the condition of the trailer hitch. Pay special attention to the presence of the latch cotter pin.

On service 2:

- - check the free axial travel of the towing device hook, which should not exceed 6.5 mm;

- - use two grease fittings to lubricate the stem and the nut of the tow hitch hook;

- - tighten the nuts of the bolts of the fuel tank brackets.

When service C:

- - check the state of the frame by external inspection. The presence of cracks, traces of corrosion on the shelves of the spars and cross members is not allowed;

- - check the presence of all rivets, in case of absence - install a bolt with a nut.

During maintenance of the hook-and-loop hitch, check the free play of the hook, which should not exceed 0.5 mm.

Please note that excessive hook play cannot be reduced by tightening or loosening castle nut 1.

The flanges together with the elastic element (buffer) 4 are placed in the housing 3 between the wall and its cover 6, so tightening the nut will reduce the total thickness of the flanges with the elastic element and increase the free play of the hook 7 together with the elastic element inside its housing.

If the nut is unscrewed, then the free play of the hook will increase by moving it inside the elastic element.

An increase in the free play of the hook can occur due to shrinkage of the elastic element. In this case, it is necessary to install additional ring gaskets between the flanges and the elastic element.

When servicing the fifth wheel coupling, check the condition of the springs of the locking fist and latch.

Periodically cover the surface of the base plate with a thin layer of grease, and lubricate the fingers and hinges of the fifth wheel coupling through grease fittings until fresh grease is squeezed into the gaps.

The towing device is also periodically lubricated in accordance with the chemotological map.