Pressure plate

The thickness of the disc body, measured by the boss of the fastening of the paired tangential spring plates - 25.74 ÷ 26.26 mm.

The difference in sizes within one part should not be more than 0.21 mm.

When repairing the pressure plate, turning the working surface to a size of at least 24.7 mm is allowed.

The permissible imbalance of the pressure plate is 90 g.

The non-flatness of a new or repaired disc is no more than 0.1 mm. The warping of the pressure plate without repair is allowed to be no more than 0.8 mm.

Pressure springs

Number of springs - 16.

Length of the spring in a free state is 61.7 ÷ 63.0 mm.

Length of the spring under load 628 ÷ 736 N - 45 mm.

Permissible (without replacing the spring) force from the spring when it is compressed to a length of 45 mm - 600 N, no less.

Clutch pressure plate lever and lever joints

Diameter of the holes in the pressure plate lever for the needle bearing - 11.42 ÷ 11.47 mm.

Permissible size of the holes in the lever without repair - 11.49 mm. Number of levers - 4.

The diameter of the fork and lever pins is 8.17 ÷ 8.20 mm.

The permissible size of the pin without repair is 8.15 mm.

The diameter of the holes in the support fork of the lever and in the eyes of the pressure plate for the lever pin is 8.200-8.258 mm.

The permissible size of the holes without repair is 8.3 mm.

The number of needle rollers in one lever hinge is 19.

The diameter of the needle roller is 1.59 ÷ 1.60 mm.

If the wear of the fingers or holes of the lever, lever fork and pressure plate bracket exceeds the permissible values, they should be replaced.

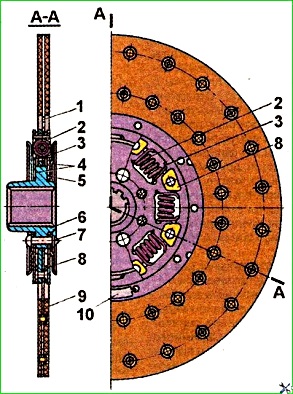

Driven disk and hub assembly

The driven disk (Fig. 1) is made of grade 50 steel sheet.

The diameter of the driven disk is 342 mm. Steel disc thickness - 1.8 mm.

Disc thickness with friction linings - 9.44 ÷ 10.16 mm.

Distance from the working surface of the lining to the rivet head - 1.20 ÷ 1.95 mm.

When the linings are worn down to the rivet heads, the disc or linings should be replaced.

The outer diameter of the friction linings is 339÷340 mm, the inner diameter is 186-187 mm.

The thickness of the friction linings is 3.9÷4.1 mm.

The diameter of the holes in the linings for the rivets is 4.0÷4.3 mm.

The diameter of the holes in the linings for the rivet heads is 9.5÷9.86 mm.

The thickness of the bridge in the friction lining socket for the rivet is 1.25÷1.50 mm.

The driven disk hub is made of steel 40X. Nominal width of the splined groove of the hub - 5.89 ÷ 5.94 mm.

Permissible width of the splined groove without repair - 6.05 mm.

If the splined groove wears above the permissible values, the hub should be replaced.

Non-flatness of the working surface of the driven steel disk - no more than 0.3 mm.

Non-flatness of the disk assembled with friction linings - no more than 0.5 mm.

The runout of the working surface of the driven disk assembled with friction linings when installing the hub on a splined mandrel is allowed to be no more than 1.0 mm.

If the rivets of the friction linings are loosened or the linings are worn above the permissible values, the friction linings should be replace.

Permissible imbalance of the driven disk - 25 g cm.

Elastic coupling (damper) springs

Number of springs - 8.

Spring length: in a free state - 24.35÷24.65 mm; under a load of 500÷650 N, - 22.5 mm; when compressed until the coils touch - 21÷22 mm.

Clutch release sleeve

The distance between the clutch cheeks under the clutch release fork is 85.54÷85.77 mm.

The diameter of the clutch hole for the journal of the gearbox input shaft bearing cap is 47.60÷47.65 mm.

The permissible size without repair is 47.90 mm.

If the wear of the clutch hole for the bearing cap journal exceeds the permissible value, the clutch should be replaced.

The diameter of the clutch neck under the fixed ring of the clutch release bearing is 55.002÷55.032 mm.

Clutch release spring

The length of the spring in free state - 33.5 mm, no more.

Spring length under a load of 20÷30 N - 56 mm.

Permissible (without replacing the spring) force from the spring when it is stretched to a length of 56 mm - 15 N, no less.

Clutch release fork

Diameter of the fork bearing journals - 24.955÷25.000 mm.

Permissible size of the fork journals without repair - 24.92 mm.

If the wear of the clutch release fork bearing journals exceeds the permissible limit, the fork should be replaced.

Distance between the fork horns - 86.00÷86.46 mm.

Permissible size between the fork horns without a remounting - 88 mm.

It is recommended to repair the fork by surfacing with subsequent processing.

Misalignment of the bearing journals of the clutch release fork relative to their common axis - no more than 0.02 mm over a length of 40 mm from the ends.

If the misalignment is higher than the permissible value, the fork should be straightened.

Clutch release fork flange

The diameter of the hole for the fork is 25.06 ÷ 25.13 mm, permissible without repair - 25.2 mm.

The outer diameter of the flange is 41.95-42.00 mm, permissible without repair - 41.90 mm.

If the outer diameter of the flange is worn above the permissible value, the flange should be replaced.

Fork lever clutch release

The diameter of the lever bushing hole for the pusher pin is 12.29÷12.40 mm.

If the bushing hole wears down to 12.6 mm, it should be replaced.

If the thread in the hole for the fork lever tie bolt is damaged, it is recommended to weld the hole, drill a new one and cut the thread.