Replace pistons when the groove of the upper piston ring or piston skirt is worn

In partially worn cylinders, install pistons of the same size (nominal or repair) as the pistons that previously worked in this engine had.

It is advisable to select a set of larger pistons to reduce the gap between the piston skirt and the cylinder bore.

In this case, check the gap between the piston skirt and the cylinder mirror in the lower, least worn part of the cylinder. Do not allow the gap in this part of the cylinder to decrease to less than 0.02 mm.

Spare parts include pistons along with piston pins and retaining rings matched to them (see Table 2 Dimensions of UAZ-3151 engine parts according to the catalog).

To select pistons of nominal size, they are sorted by the outer diameter of the skirt.

The letter designations of the size group, which are indicated in the table, are stamped on the piston heads. 1 Dimensions of UAZ-3151 engine parts according to the catalog

On repair size pistons, their diameter is also stamped.

In addition to selecting pistons for cylinder liners based on skirt diameter, they are also selected based on weight.

The difference in weight between the lightest and heaviest piston for one engine should not exceed 4 g.

When assembling, install pistons in sleeves of the same group.

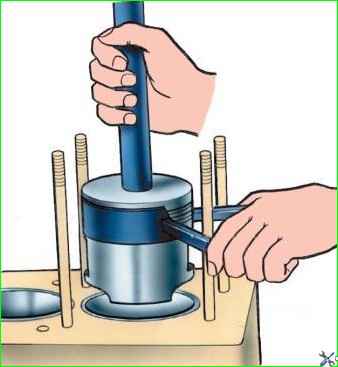

Install the pistons into the cylinders using the model 59–85 tool shown in Fig. 1.

When installing pistons into cylinders, the “front” mark cast on the piston should face the front of the engine; on a piston with a split skirt, the “back” mark should face the clutch housing.

On all repair size pistons, the holes in the bosses for the piston pin are made of a nominal size, divided into groups.

If necessary, these holes are bored or reamed to the nearest repair size with a tolerance of -0.005 -0.015 mm.

Taper and ovality of the hole – no more than 0.0025 mm.

When processing, ensure that the hole axis is perpendicular to the piston axis, the permissible deviation is no more than 0.04 mm over a length of 100 mm.