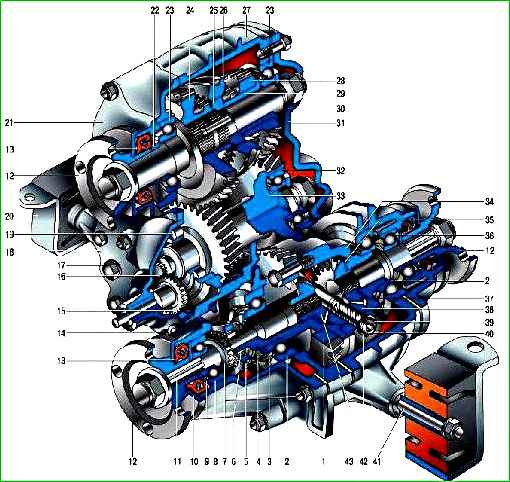

The transfer case is designed to change the torque in magnitude and distribute it between the front and rear drive axles

The vehicle is equipped with a two-speed transfer case with an interaxle differential lock.

The transfer case is controlled (selection of high or low gear, engagement/disengagement of the differential lock) by one lever through a mechanical lever drive.

The transfer case has two gears with gear ratios of 1.200 and 2.135. The front and rear axles rotate constantly and are connected by an interaxle differential.

To improve the vehicle's cross-country ability, the differential is locked, while the rear and front drive shafts are rigidly connected to each other.

The transfer case is attached to the body floor on two rubber-metal brackets.

To adjust its position relative to the intermediate shaft flange, the holes in the brackets are made oval, and adjusting linings can be installed between them and the body.

The transfer case body parts are cast from aluminum alloy and connected to each other with studs and nuts.

A hatch is made in the upper part of the crankcase, closed by a stamped steel cover.

The front cover is centered on the crankcase by two mounting pins.

Cardboard gaskets are located between the covers and the crankcase (during repairs, you can use them instead of sealant).

All shafts (including the speedometer drive shaft), as well as the gearshift fork and differential lock rods, are sealed with oil seals.

There are two holes in the front cover - a filler (also a control hole) and a drain hole.

The drive shaft is mounted on two ball bearings in the front cover and crankcase seats.

The inner ring of the front bearing is clamped between the shaft flange and the thrust ring by the self-locking nut of the shaft flange.

The inner ring of the rear bearing is clamped between the shaft flange and the thrust washer by the nut on the rear end of the shaft.

The nut is locked by pressing its edge into the grooves on the shaft.

The drive shaft is fixed from axial displacement by the mounting ring in the groove on the outer ring of the rear bearing and clamped between the crankcase and the rear cover.

There are two drive gears on the drive shaft. The front (large) one is the highest gear, it rotates freely on the shaft journal.

The rear (smaller) one is the lowest gear, it rotates freely on the sleeve, mounted on the shaft with tension. The gears have two rims.

The helical (large) rims are in constant engagement with the corresponding gears of the intermediate shaft, and the gear shift clutch is connected to the spur (small) rims when the gear is engaged.

The clutch moves along the hub, which is rigidly mounted on the shaft splines between the drive gears.

In the middle position of the clutch, both gears are disengaged (4 neutrals) and the torque from the engine is not transmitted to the wheels.

The intermediate shaft is a block of two helical gears that are in constant engagement with the gears of the drive shaft.

The front gear is also in engagement with the driven gear, which is fixed to the differential housing.

The intermediate shaft rotates in two bearings:

front - roller, rear - ball. The shaft is secured against axial displacement by a mounting ring in the groove of the outer ring of the rear bearing, which is clamped between the crankcase and the rear cover (the same as the drive shaft).

A steel drive gear of the speedometer drive is pressed into the front end of the shaft.

The driven gear of the speedometer drive is plastic, mounted on a shaft rotating in the sleeve of the speedometer drive housing. The housing is fixed to the front cover of the transfer case.

On the VAZ-21214 with distributed fuel injection, in addition to the mechanical drive of the speedometer, a speed sensor is installed on the transfer case.

The front end of the front axle drive shaft rests on a ball bearing in the front axle drive housing, fixed to the front cover of the transfer case.

The inner ring of the bearing is clamped between the shaft flange and the thrust ring of the self-locking nut of the shaft flange.

The bearing is secured from axial displacement by a retaining ring entering the groove of the front axle drive housing.

The rear splined end of the shaft is connected to the front axle drive gear of the differential. The spur gear on the shaft serves to lock the differential.

The design and installation of the rear axle drive shaft is similar, but there is no gear on it.

The differential housing is split, both parts are connected with six bolts.

The same bolts fasten the driven gear to the differential housing. The latter is mounted on two ball bearings.

The inner race of the front bearing is held from displacement by a spacer spring washer resting on a retaining ring in the groove of the differential housing.

A mounting ring, clamped between the front cover of the transfer case and the front axle drive housing, enters the groove on the outer ring of the bearing.

Thus, the differential housing is held from axial displacement by the front bearing; the rear bearing is not fixed.

The front part of the differential housing has splines along which the locking clutch moves.

When the lock is engaged, the clutch connects to the gear on the front axle drive shaft, connecting it to the differential housing.

The satellite axle is installed in the holes of the differential housing, held by two retaining rings. Under one of the rings there is a spring washer that prevents axial movement of the satellite axle.

The satellites (bevel gears) located on the axle are in constant engagement with the axle drive gears.

Thrust washers are installed between the differential housing and the satellites. Their thickness is selected so that the axial clearance of the axle drive gears does not exceed 0.10 mm, and the torque of resistance to rotation is 14.7 Nm.

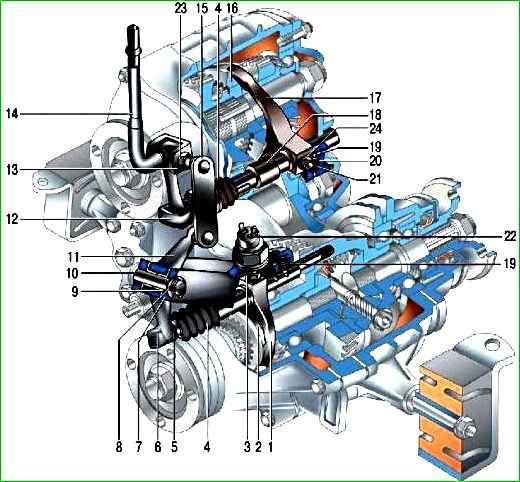

The transfer case is controlled manually, with a mechanical lever drive.

The driver changes gears with the rear lever, and engages the differential lock with the front lever.

The design of the gearbox control drives is similar.

The lever swings in the longitudinal direction on an axis mounted in the bracket lugs at the front of the transfer case. To reduce friction, plastic bushings are inserted into the lever hole.

The lower end of the lever enters the groove of the rod and is fixed with a figured spring.

The other end of the rod is connected to the fork of the corresponding clutch (gear shift or differential lock) and is locked with a bolt.

The rod at the exit from the box is sealed with a gland and protected from dust by a rubber corrugated cover.

A ball lock is used to fix the drive in the selected position - a spring-loaded ball enters the grooves on the rods.

There are three of them on the gear shift rod - for "neutral", high and low gears, on the differential lock rod - two ("on" and "off").

A switch is screwed into the front axle drive cover, closing the circuit of the control lamp when the lock is turned on differential.

Possible malfunctions of the transfer case

Reason for failure - Troubleshooting

Vibration of the transfer case and the body floor (in the area of the front seats) in all driving modes

Failure of the flexible coupling of the intermediate shaft - Replace the flexible coupling

Vibration of the transfer case and the body floor (in the area of the front seats) when starting the car and accelerating to 80 km / h

The transfer case supports and the rear support of the power unit are not tightened or are damaged - Tighten the nuts and bolt securing the supports, replace the damaged supports

Tight turning or jamming in one of the planes of the joints of the front or rear cardan shafts - Repair the cardan joints or replace the joints as an assembly

Incomplete release of the parking brake - Adjust the parking brake drive brakes

Difficult to turn the constant velocity joint of the intermediate shaft - Check the condition of the boot and joint. If the joint parts are worn or damaged, replace the joint assembly

Vibration of the transfer case and the body floor (in the area of the front seats) during steady-state driving (most typical at a speed of 80-90 km / h)

Increased imbalance of the driveshafts - Repair or replace the driveshafts

Increased imbalance of the transfer case center differential - Replace the center differential

Joining of the front or rear driveshaft constant velocity joints - Repair the joints or replace the driveshafts as an assembly

Joining of the constant velocity joint of the intermediate shaft - Check the condition of the boot and joint. If the parts are damaged, the joint must be replaced

Loose nuts and bolts for fastening the engine mounts or damaged engine mounts - Tighten the nuts and bolts for fastening the mounts or replace the mounts

Bent bolts and flange of the flexible coupling of the intermediate shaft - Replace the bolts or the intermediate cardan shaft

Difficult gear shifting or differential locking

Seizure of the couplings on the splines of the hub, differential housing, front axle drive shafts - Clean up burrs, nicks or scuffs, replace damaged parts

Nicks on the teeth of the small ring gear of the high or low gears, as well as on the teeth of the couplings and on the splines of the front axle drive shaft - Clean up nicks and burrs, replace damaged parts

Difficult gear shifting or differential lock

Jamming of couplings on the splines of the hub, differential housing, front axle drive shafts - Clean burrs, nicks or scuffs, replace damaged parts

Nicks on the teeth of the small ring gear of the high or low gears, as well as on the teeth of the couplings and on the splines of the front axle drive shaft - Clean nicks and burrs, replace damaged parts

Bent fork or rod - Straighten deformed parts

Jamming of the drive lever on the axles - Remove the lever, clean the axles and bushings. Replace damaged parts. Lubricate the parts with Litol

Contamination or corrosion in the control drive joints - Clean the parts, replace the damaged ones

Spontaneous disengagement of gears or differential lock

Worn teeth of gears and clutches - Replace the worn parts

Reduced elasticity of the locking springs or wear of the locking parts - Replace the springs or worn parts

Incomplete gear engagement and lack of differential lock due to deformation of drive parts or due to nicks on gears, clutches and splines - Straighten or replace the deformed parts, clean up nicks and burrs, replace the damaged parts

Oil leak

Damaged sealing gaskets - Replace the gaskets

Loose nuts and studs securing the covers to the crankcase - Tighten nuts and studs

Worn or damaged shaft seals - Replace seals

Worn transfer case drive rod sealing rings - Replace sealing rings

Presence of cavities, porosity and damaged surfaces of body parts - Replace body parts

Method for determining the causes of vibration of the transfer case and body floor (in the area of the front seats)

First of all, note at what speed the vibration of the transfer case occurs, then proceed to determine the causes of vibration.

If vibrations appear after repair or replacement of transmission units:

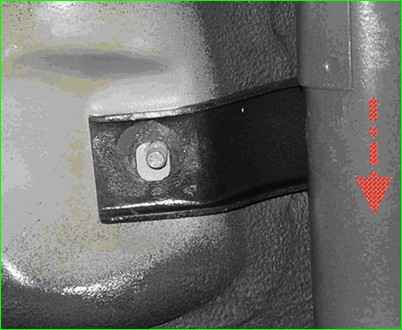

Raise the car on a lift to a height convenient for work, loosen the nuts securing the crossmember of the gearbox support to the car body and move the unit to the left until it stops (Fig. 3).

Tighten the nuts in this position. The arrow in the figure indicates the direction of movement of the car.

If the defect is not eliminated, center the transfer case:

- install return the transfer case gearshift handle to the neutral position.

Start the engine, engage second gear with the gearshift lever.

The car should not move. Raise the car on a lift to a height convenient for work;

- - loosen the six nuts securing the transfer case to the body;

- - turn the transfer case on the studs, achieve a position of the transfer case relative to the body at which the vibration of the intermediate propeller shaft is minimal;

- - hold this mode, tighten the nuts securing the transfer case to the body

- - lower the car, stop the engine.

Attention. It is prohibited for people to be inside the vehicle while it is being lifted and repaired.

When working under the vehicle, exercise extreme caution. To avoid injury, keep your hands and tools away from rotating transmission parts.

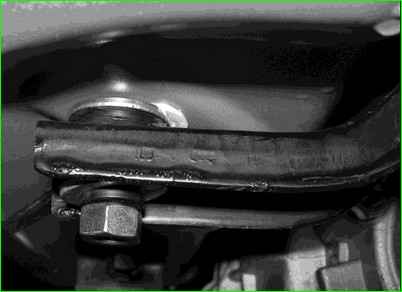

If the defect is not eliminated, install additional washers (Fig. 4) 2.5 mm thick between the crossmember of the rear support of the transfer case and the car body (one washer for each stud).

If the defect is not eliminated, reinstall the rear propeller shaft, for which:

- - unscrew the bolts securing the propeller shaft shaft to the flanges of the transfer case and the rear axle gearbox;

- - turn the shaft relative to the flanges of the transfer case and the rear axle gearbox by 180°;

- - secure the shaft in this position.

If the defect is not eliminated, reinstall the front propeller shaft in the sequence specified above.

If the defect is not eliminated, replace the rear propeller shaft.

If the defect is not eliminated, replace the front propeller shaft.

If the defect is not eliminated, replace the intermediate propeller shaft.