An electrical circuit consists of switches, relays, motors, fuses, circuit breakers, wires and connectors that connect the current consumer to the battery and the body.

To help you find sources of electrical system malfunction, this article provides vehicle electrical system diagrams.

Before attempting to determine the source of a malfunction, study the corresponding electrical system diagram to get an idea of the elements of this circuit.

The number of possible sources of malfunction can be reduced by checking the operation of other elements included in the circuit.

If several elements or circuits fail at the same time, it is possible that the fuse common to these circuits or elements is faulty, or the connection to the body - "ground" is broken.

The causes of malfunction are loose or oxidized connectors, poor contact with the body, blown fuses or faulty relay.

Visually inspect the condition of all fuses, wires, and connectors in the faulty circuit before testing the remaining components.

Use the electrical schematics to identify the terminals that need to be tested to determine the source of the fault.

The basic tools needed to locate the source of the fault are a tester or voltmeter, a 12-volt test light, an ohmmeter, a battery, and a set of test leads, preferably with a circuit breaker or fuse that is used to bypass the wires or components being tested.

In addition to a broken wire connection in an electrical system, there are two other basic types of faults that can occur - an open circuit or a short circuit.

A circuit is opened due to a break, which interrupts the current, causing the electrical component to turn off.

To determine the integrity of the circuit, connect a circuit tester or voltmeter: one lead to the negative battery terminal or a grounded component, and the other lead to a contact in the circuit being tested, preferably closest to the battery or fuse.

The section of the circuit being tested should be live from the battery, unless the battery connector is dead or the fuse has blown (remember that some electrical circuits are only turned on when the ignition key is turned to a certain position).

Turn the circuit on, then connect the tester probe to the connection closest to the circuit breaker on the side of the component being tested.

If there is voltage (as indicated by the test lamp lighting up or the voltmeter reading), then there is no break in the section of the circuit between the corresponding connection and the switch.

If there is a section where there is no voltage, then the circuit is open between this point and the point of the previous test where there was voltage.

The open circuit is caused by a damaged or loosened component connector.

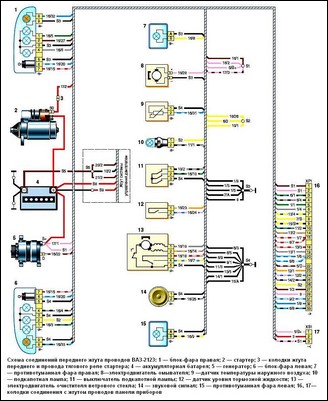

1. BA3-2123 front wiring harness connection diagram: 1 - right headlight; 2 - starter; 3 - front wiring harness pads and starter traction relay wires; 4 - battery; 5 - generator; 6 - left headlight; 7 - right fog lamp; 8 - washer motor; 9 - outside air temperature sensor; 10 - underhood lamp; 11 - underhood lamp switch; 12 - brake fluid level sensor; 13 - windshield wiper motor; 14 - horn; 15 - left fog lamp; 16, 17 - connector pads with instrument panel wiring harness

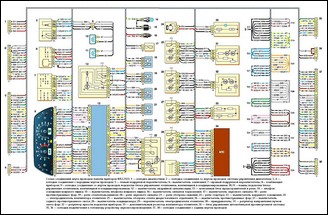

2. Wiring harness connection diagram for BA3-2123 instrument panel: 1 - diagnostic connector; 2 - connector pad with engine management system wiring harness; 3, 4 - connector pads with front wiring harness; 5 - left steering column switch; 6 - ignition switch; 7 - right steering column switch; 8 - instrument cluster; 9 - connector block with wiring harness of heating, ventilation and air conditioning control unit backlight; 10,11 - backlight lamps of heating, ventilation and air conditioning control unit; 12 - hazard warning switch; 13 - fuse box and relay; 14 - glove compartment light; 15 - glove compartment light switch; 16 - brake light switch; 17 - horn switch; 18 - fog light relay; 19 - power window relay; 20 - horn relay; 21 - seat heating relay; 22 - starter relay; 23 - exterior lighting switch; 24 - heater blower motor; 25 - tailgate glass heating switch; 26 - fog light switch; 27 - rear fog light switch; 28 - air conditioning switch; 29 - heater motor switch; 30 - cigarette lighter; 31 - headlight beam direction controller; 32 - instrument lighting brightness controller; 33 - heater blower additional resistor; 34 - vehicle anti-theft alarm system control unit; 35, 36 - connector pads to the head unit; 37, 38 - connector pads to the rear wiring harness

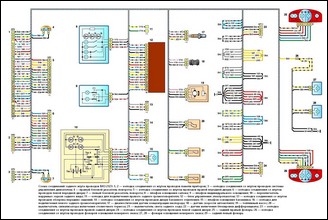

3. Wiring diagram of the rear wiring harness BA3-2123: 1, 2 - connector pad to the instrument panel wiring harness; 3 - Connector with engine management system wiring harness; 4 - Right side direction indicator; 5 - Connector with right front door wiring harness; 6 - Connector with left front door wiring harness; 7 - Left side direction indicator; 8 - Interior light; 9 - Individual lighting light; 10 - Outside rearview mirror switch; 11 - Connector for connecting the right rear speaker; 12 - Power package control unit; 13 - Connector with front seat heating wiring harness; 14 - Connector with tailgate wiring harness; 15 - Trunk light; 16 - Connector for connecting the left rear speaker; 17 - Oxygen concentration diagnostic sensor; 18 - Vehicle speed sensor; 19 - Fuel pump; 20 - Parking brake indicator switch; 21 - Reversing light switch; 22 - Differential lock engagement sensor; 23 - Connecting block with wiring harness of right rear door; 24 - Connecting block with wiring harness of left rear door; 25 - Right rear light; 26 - Connecting block with wiring harness of license plate lights; 27, 28 - License plate lights; 29 - Rear left lamp

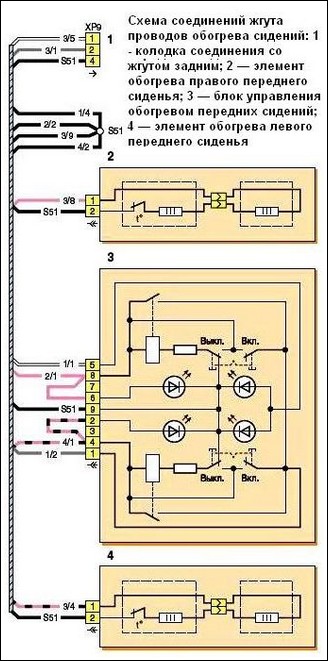

4. Seat heating wire harness connection diagram: 1 - connector block with rear harness; 2 - right front seat heating element; 3 - front seat heating control unit; 4 – Left front seat heating element

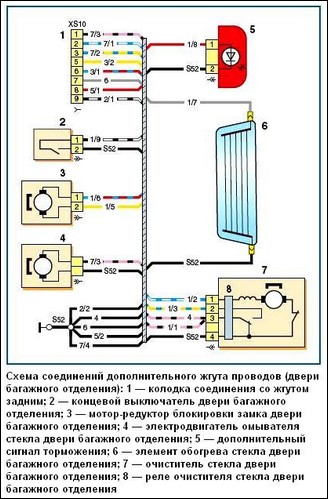

5. Additional wiring harness (tailgate) connection diagram: 1 – connector block with rear harness; 2 – tailgate limit switch; 3 – tailgate lock motor-reducer; 4 - tailgate glass washer motor; 5 - additional brake light; 6 - tailgate glass heating element; 7 - tailgate glass wiper; 8 - tailgate glass wiper relay

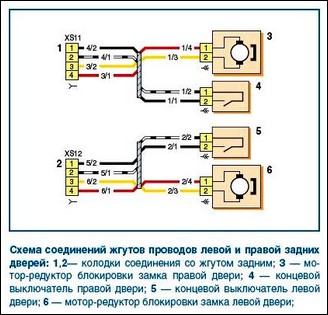

6. Wiring harness connection diagram for left and right rear doors: 1, 2 - connector blocks with rear harness; 3 - right door lock motor-reducer; 4 - right door limit switch; 5 - left door limit switch; 6 - left door lock motor-reducer

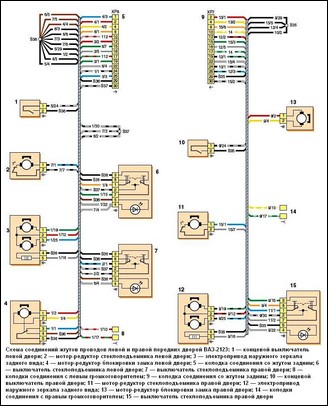

7. Wiring harness connection diagram for the left and right front doors of the BA3-2123: 1 - left door limit switch; 2 - left door window regulator motor-reducer; 3 - outside rearview mirror electric drive; 4 - left door lock lock motor-reducer; 5 - rear harness connection block; 6 - left door window regulator switch; 7 - right door window regulator switch; 8 - left speaker connection blocks; 9 - rear harness connection block; 10 - right door limit switch; 11 - right door window regulator motor-reducer; 12 - outside rearview mirror electric drive; 13 - right door lock regulator motor-reducer; 14 - right speaker connector pads; 15 - right door window regulator switch

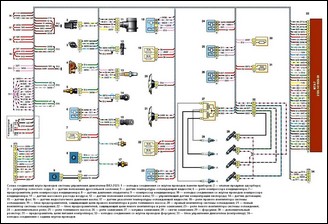

8. Wiring harness connection diagram for the engine management system BA3-2123: 1 - connector with the instrument panel wire harness; 2 - purge valve of the adsorber; 3 - idle speed control valve; 4 - throttle position sensor; 5 - coolant temperature sensor; 6 - air conditioning compressor relay; 7 - air conditioning compressor relay fuse; 8 - refrigerant pressure sensor; 9 - air conditioning compressor; 10 - connector with the air conditioning compressor wire harness; 11 - mass air flow sensor; 12 - crankshaft position sensor; 13 - control oxygen concentration sensor; 14 - knock sensor; 15 - phase sensor; 16 - low oil pressure sensor; 17 - coolant temperature gauge sensor; 18 - right cooling fan relay; 19 - fuse box protecting the right fan circuits and the fuel pump relay; 20 - right cooling fan; 21 - left cooling fan; 22 - fuse box protecting the left fan and ignition relay circuits; 23 - left cooling fan relay; 24 - additional relay; 25 - fuel pump relay; 26 - ignition relay; 27 - ignition coil; 28 - spark plugs; 29 - injectors; 30 - additional resistor; 31 - controller power supply circuit fuse; 32 - connector block with injector wiring harness; 33 - engine control unit (controller); 34 - connector block with rear wiring harness

To detect the source of the short circuit, turn off power consumers - lamps, electric motors, heating elements, etc.

Remove the corresponding fuse and connect the leads of the tester or voltmeter to the fuse contacts.

Turn on the power in the circuit; Remember that some electrical circuits are only activated when the ignition key is turned to a certain position.

If there is voltage in the circuit (as indicated by the indicator lamp or the voltmeter reading), then there is a short circuit in the circuit.

If there is no voltage when checking, and the fuse still blows when the same load is connected, then the load element has failed.

The negative terminal of the battery is connected to the "ground" - the body, engine or gearbox.

A poor or oxidized mount can lead to failure of the element or malfunction.

Remember that many cars use "ground" wires between certain elements, such as the engine/transmission and the body, that is, in places where there is no direct contact between metal elements due to soft rubber mounts or a layer of paint.

To check the reliability of the element grounding, it is necessary to disconnect battery and connect one of the ohmmeter leads to a reliably grounded element.

Connect the other lead to the wire or connection to the body that needs to be checked.

The resistance shown by the ohmmeter should be zero, otherwise check the connection as described below.

If there is any doubt about the reliability of the contact with the "ground", disassemble the connection, remove dirt and clean the contacts.

When reassembling, tighten the connector fastening, for which purpose apply a layer of technical petroleum jelly or silicone grease to prevent corrosion.

The integrity test is carried out to ensure that the circuit, its section or element conducts current.

Disconnect the wires from the battery terminals and connect the probe of the test lamp with its own power source, for example, a device for checking the integrity of circuits - to one end of the circuit, and the other probe to the other end of the circuit.

If the lamp lights up, it means that the circuit is not interrupted and conducts electric current. Switches can be checked in the same way.