In accordance with the maintenance regulations, the timing belt is replaced every 120 thousand km of vehicle mileage or after 6 years (whichever comes first), regardless of its condition

Failure of the belt (breakage or shear of the teeth) will lead to the valves hitting the pistons due to the misalignment of the rotation angles of the crankshaft and camshafts and, as a result, to expensive engine repairs.

Therefore, we recommend checking the condition of the belt at each maintenance of the car.

We perform the work on an inspection pit or overpass.

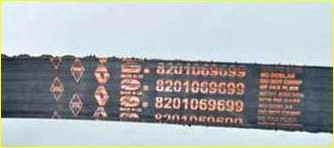

The surface of the toothed part of the belt should not have folds, cracks, undercuts of the teeth and delamination of the fabric from the rubber.

The reverse side of the belt should not have wear that exposes the cord threads and traces burning.

There should be no delamination on the end surfaces of the belt.

The belt should also be replaced if traces of oil are found on it.

It should be noted that there are no marks on the engine toothed pulleys for setting the engine valve timing - at authorized dealer services, when replacing the timing belt, a special tool and devices are used to fix the crankshaft and camshafts.

When replacing the belt, you need to change not only the toothed belt, but also its tension and support rollers, as well as the bolt for fastening the auxiliary drive pulley.

Therefore, we recommend that operations to replace the timing belt be performed at a specialized service that has the necessary equipment and spare parts, at the same time, an experienced driver with the appropriate skills in repairing modern engines will be able to perform operations to replace the timing belt independently.

For evaluation condition and replacement of the timing belt, remove the right support of the power unit and the right mudguard of the engine compartment.

For clarity, we show the operation on a dismantled engine.

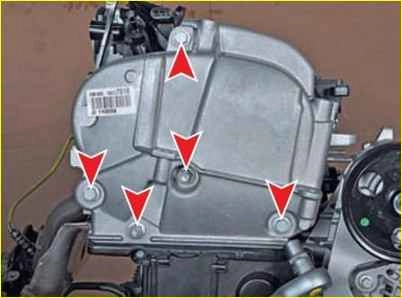

Using a 13 mm head, unscrew the three bolts and two nuts securing the upper timing belt cover

Remove the cover

Using an 18 mm head, turn the crankshaft clockwise by the bolt securing the auxiliary drive pulley and visually assess the condition of the timing belt, as described above.

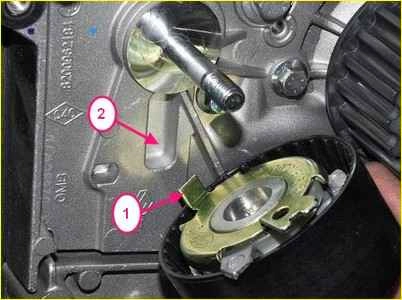

You can assess the belt tension by the location of the belt tension roller indicators.

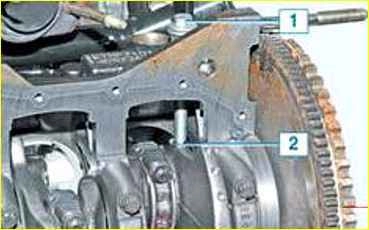

With normal belt tension, the movable indicator 1 should coincide with the notch of the fixed indicator 2 of the tension roller (shown for clarity with the lower timing drive cover removed).

If the movable indicator is slightly offset counterclockwise relative to the fixed one, then the belt tension is insufficient and the belt can be tightened.

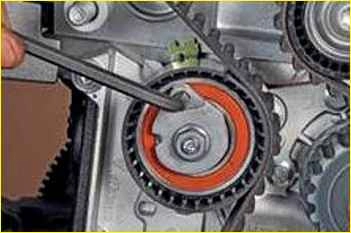

To do this, loosen the tension roller mounting nut with a 13 key and turn the roller clockwise (tightening the belt) with a 6 Allen key until the indicators align.

Holding the roller in this position, tighten its mounting nut.

Having turned the crankshaft two turns clockwise by the accessory drive pulley mounting bolt, check the belt tension again and repeat the adjustment if necessary.

Reinstall the dismantled parts in the reverse order.

To replace the timing belt, remove the accessory drive belt and the upper timing belt cover.

Before unscrewing the accessory drive pulley mounting bolt, it is necessary to block the crankshaft from turning.

To do this, an assistant must turn on the gears to the highest gear, press the brake pedal and apply the parking brake.

Using a 18 mm socket, unscrew the bolt securing the auxiliary drive pulley

Remove the bolt with the washer

Removing the auxiliary drive pulley

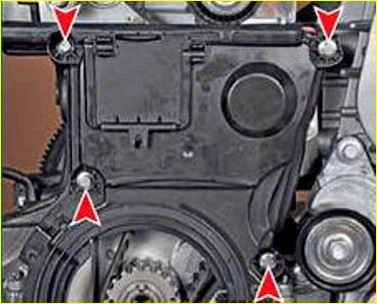

Using an 8 mm socket, unscrew the four bolts securing the lower drive cover Timing belt

Remove the lower cover

In order not to disturb the valve timing phases, before removing the timing belt, it is necessary to set the crankshaft and camshafts to the TDC (top dead center) position of the compression stroke of the 1st cylinder.

To turn the crankshaft, screw the auxiliary drive pulley mounting bolt back into place, installing a spacer (bushing or set) between the bolt and the end of the shaft. washers).

The crankshaft can also be turned by rotating the (installed) front right wheel clockwise with the gearbox in top gear.

To make it easier to turn the shaft, unscrew the spark plugs.

To determine the position of the camshafts, remove two rubber-metal plugs from the holes in the left end of the cylinder head.

Remove the air intake with the air tract resonator.

Poke the center of the plug with a screwdriver

Using the screwdriver as a lever, remove the plug from the hole in the cylinder head.

Also remove the other plug.

Turn the crankshaft clockwise until the grooves on the ends of the camshafts take a horizontal position (are parallel to the plane of the joint of the cover and the cylinder head) and are shifted downwards relative to the axes of the camshafts.

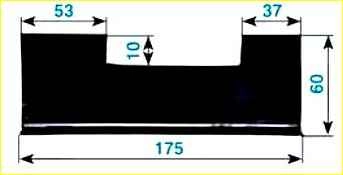

To fix the camshafts when replacing the belt, a simple device can be made from a 5 mm thick metal plate (see sketch).

We install the device in the grooves of the shafts.

To check that the crankshaft is in the TDC position of the pistons of the 1st and 4th cylinders, a threaded hole is provided on the front wall of the cylinder block (under the starter), into which a plug is screwed.

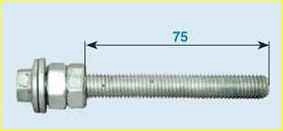

Using the E-14 head, we unscrew the plug. A special installation pin (with a threaded section length of 75 mm) must be screwed into the hole.

When the crankshaft is in the TDC position of pistons of the 1st and 4th cylinders, the pin must rest against the milled area on the crankshaft cheek and block the shaft when trying to turn it clockwise.

You can use the M10 bolt as an installation pin.

Screw two adjusting nuts onto the bolt and lock them so that the length of the threaded part of the bolt is equal to 75 mm.

The assembled device (installation pin) is screwed into the threaded hole of the cylinder block.

When the crankshaft is in the TDC position of pistons of the 1st and 4th cylinders, the installation pin 1 should be screwed into the hole to the end of the thread and rest against the milled area 2 on the crankshaft cheek (shown with the oil pan removed).

Inserting the factory TDC locking device

In this case, the crankshaft cannot be turned clockwise.

If, when screwing in the installation pin, it rests, and the end of the adjusting nut on the pin does not touch the end of the boss of the hole in the cylinder block (there will be a gap between the nut and the boss), then you need to turn the crankshaft a little (after removing the device from the grooves of the camshafts) counterclockwise.

Then you need to screw the installation pin into the hole in the cylinder block until the end (until the ends of the pin nut and the boss of the hole in the block touch) and turn the crankshaft clockwise until the shaft cheek pad stops in the pin.

We install the device for fixing the camshafts, if it was removed.

After loosening the tension roller mounting nut with a 13 key, turn the roller counterclockwise, reducing the tension of the timing belt

Remove the belt from the tension roller

Then remove it from the pulleys of the coolant pump, crankshaft and camshafts.

When replacing the belt, you also need to replace the tensioner and support rollers.

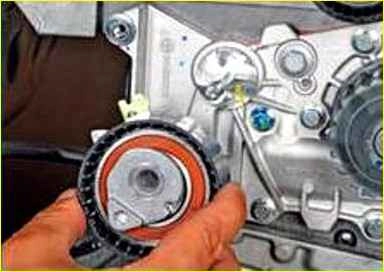

Unscrew the tension roller mounting nut and remove it from the coolant pump housing stud.

Using a Torx-50 wrench, unscrew the support roller mounting screw.

Remove the support roller and its bushing.

Remove the support roller and its bushing. Install a new support roller in the reverse order.

When installing a new timing belt (which has arrows on it), orient it so that the arrows coincide with the direction of belt movement (clockwise).

Install the belt on the toothed pulleys of the crankshaft, coolant pump and the pulleys of the camshafts. Then, simultaneously put the belt on the new tension roller and install the roller on the stud of the coolant pump housing.

When installing the tension roller, insert the bent end 1 of the roller bracket into the recess 2 of the coolant pump housing.

Adjust the tension of the timing belt.

Unscrew the installation pin from the hole in the cylinder block and remove the device for fixing the camshafts. shafts.

Turn the crankshaft two turns clockwise until the grooves on the ends of the camshafts take the desired position.

Check the valve timing and belt tension.

If necessary, repeat the operations for installing the timing belt. We screw the plug into the hole in the cylinder block.

With light blows of a hammer with a plastic striker, we press new plugs into the holes in the cylinder head.

Further assembly of the engine is carried out in the reverse order.

Replace the bolt securing the auxiliary drive pulley with a new one and tighten it to the specified torque.

Tightening torques for fasteners when replacing the belt Timing belt:

- - bolt for fastening the right support to the body – 62 Nm;

- - nut for the bolt for fastening the cushion of the right support to the body;

- - bolt for fastening the pulley of the auxiliary drive 20 Nm, tighten further by 135˚±15˚;

- - nut for fastening the axle of the tension roller of the timing belt:

- - 1 stage – 7 Nm;

- - 2 stage – 27 Nm.

- - bolt for fastening the support roller of the timing belt – 45 Nm.