To compensate for thermal expansion of the valve relative to the valve lever, a gap between the end of the valve and the lever is structurally specified

With an increased gap, the valve will not open completely, with a reduced gap, it will not close completely.

We check and adjust the gaps when a characteristic valve knock appears. The knock is loud in the upper part of the cylinder head.

We must adjust the gaps after repairing the cylinder head.

The gaps must be measured on a cold engine, approximately 20˚ C.

The gap for the intake valves should be 0.2 +0.05 mm. For exhaust valves, the gap should be 0.4+0.05 mm.

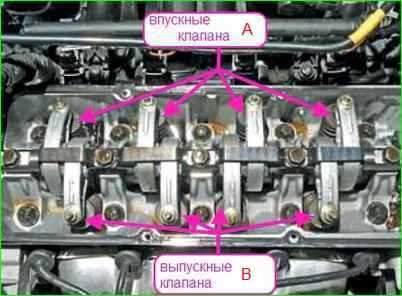

The intake valves are closer to the windshield relative to the Lada Largus car body.

A row of exhaust valves is closer to the radiator of the engine cooling system.

To measure the valve clearances, remove the cylinder head cover (see the article on removing the cover).

Unscrew the spark plugs to make it easier to turn the crankshaft.

Remove the upper timing belt cover and set the top dead center of the first cylinder at the end of the compression stroke (Checking and replacing the timing belt of the K7M engine).

Consider that the first cylinder is next to the flywheel.

The firing order of the cylinders is 1-3-4-2.

The clearances on this engine are adjusted in pairs, if the TDC of the first cylinder, then we adjust the clearances on the intake and exhaust valves of the first cylinder.

Then we turn the crankshaft clockwise by 180˚, and adjust the clearances in the third cylinder, etc.

We check the clearance with flat feeler gauges between the ends of the valve stem and the adjusting screw. The feeler gauge should move in the gap with a little effort.

If the gap size is different, then with a 10 key, loosen the tightening of the lock nut of the adjusting screw, holding the screw from turning by the flats (you can use an adjustable wrench as in the photo)

Then, turning the adjusting screw, set the desired gap.

Tighten the lock nut, holding the adjusting screw key.

Check the gap again and repeat the adjustment if necessary.

After you have adjusted the gaps in all cylinders, you need to turn the crankshaft again and check the gaps again.

After adjusting the valve clearances, assemble all the parts in the reverse order.

Start the engine and warm it up.

Listen to the operation of the valves. The engine sound should be smooth, without knocks or tightening.