Loss of pressure in the fuel system

- 1. Remove fuse #9 (fuel pump fuse) from the right fuse box

- 2. Start the engine and let it run until all the fuel in the fuel line is used up. After that, the engine will stall.

- 3. Replace the fuse.

- 4. Replace damaged chain tensioners.

- 5. After that, you can disconnect the fuel lines.

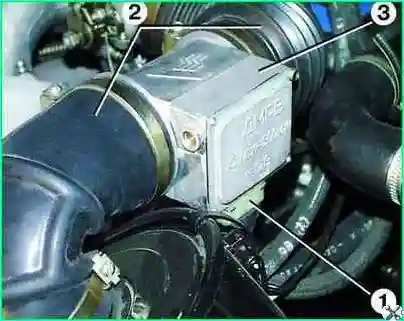

Replacing the mass air flow sensor

1. Disconnect the wire from the negative terminal of the battery.

2. Disconnect connector 1 from mass air flow sensor 3.

Loosen the clamps, disconnect the air supply hoses 2 and remove sensor 3.

3. Install the new sensor in the reverse order.

Checking the mass air flow sensor

- 1. Remove the mass air flow sensor.

- 2. Connect a voltmeter to contacts "2" and "3" of the sensor connector. Apply a direct current of 12 V to contacts "1" and "5", plus to contact 5, and minus to 1. The voltmeter should show a voltage of 1.3-1.4 V.

Then briefly short-circuit contacts "4" and "5". The voltmeter should show a voltage of about 8 V, and the platinum filament should glow red hot.

If at least one of these conditions is not met, replace the sensor.

Adjusting the content of carbon monoxide (CO) in exhaust gases

- 1. The adjustment is made on a warmed-up engine (coolant temperature 80–90 °C) with a serviceable ignition system and nominal gaps between the spark plug electrodes.

- 2. The content of CO and HC in the exhaust gases must be within the range: 0.7–0.9% CO and 1200 min¹ HC at a crankshaft speed of (800±50) min¹; no more than 0.5% CO and 600 min¹ HC at a crankshaft speed of (3150±50) min¹.

- 3. If the CO content is higher than the specified limits, adjust the CO content with screw 1 on the mass air flow sensor.

When the screw is turned clockwise, the CO content increases, and counterclockwise, it decreases. In this case, the content of CH will also be adjusted.

If it is not possible to adjust the content of CO and CH within the specified limits, it is necessary to check the serviceability of the elements of the integrated microprocessor engine management system.

Replacing the accelerator cable

1. Disconnect the wire from the "Minus" terminal of the storage battery.

2. Loosen nut 1 and remove accelerator cable 2 from sector 3 of the air throttle actuator.

3. Move seal 1 from cable tip, completely unscrew nut 2 from cable tip, pull tip 3 of cable casing out of bracket and pull cable up out of bracket through slot.

Remove tip 3 from cable by pulling it out of outer 4 and inner casings of cable.

4. Remove outer 1 and inner casings of cable from tip 2 on front shield.

5. Remove cotter pin 1 from pin 2. Move oil seal 4 and remove bracket 3.

- 6. Pull the cable through the end on the front shield into the passenger compartment.

- 7. Install the new accelerator cable in the reverse order and adjust it.

Adjusting the accelerator cable

1. Loosen nut 1 securing cable 2 to sector 3.

2. Loosen the tightening of nut 2 of the adjusting bolt 1 between the upper 4 and lower 3 levers of the accelerator pedal.

3. From the side of sector 3 of the throttle valve, pull out cable 1 until it stops. In this case, the upper lever 5 of the accelerator pedal should rest against the buffer 4 by bracket.

Tighten nut 2 of the cable mount on the sector. In this case, the throttle valve should be completely closed.

- 4. Pull the upper lever 4 of the pedal towards you until it stops. While holding the upper lever 4 of the pedal in this position, turn the lower lever 3 of the pedal until it stops in the mat and tighten nut 2 of the adjusting bolt 1

- 5. When the adjustment is correct, with the pedal fully released, the throttle valve should be fully closed, and the upper pedal arm should rest against the buffer on the bracket.

With the pedal fully depressed, the throttle valve should be fully open, and the lower pedal arm should rest against the mat.

6. The position of the cable can be adjusted by moving the tip 1 of the shell in the bracket, loosening the tightening of nut 2. After adjusting nut 2 tighten.

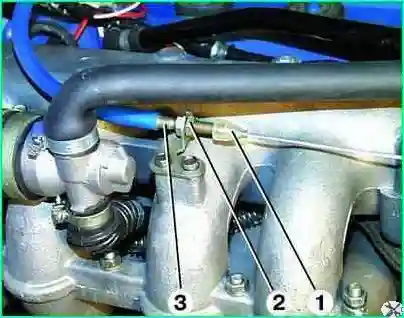

Throttle Assembly

Removal

- 1. Disconnect the wire from the negative terminal of the battery.

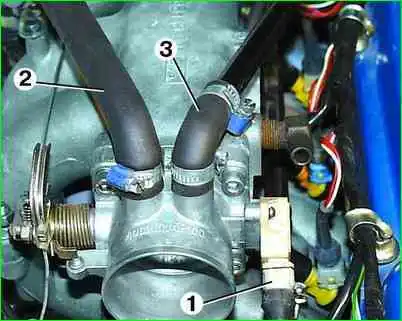

- 2. Disconnect the accelerator cable from the throttle sector

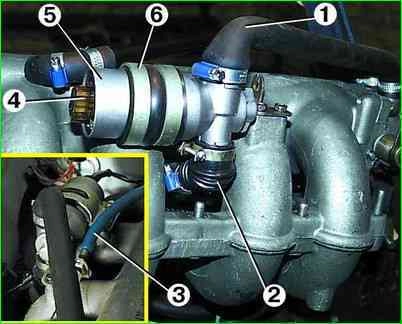

- 3. Disconnect block 1 with wires from the throttle position sensor.

Loosen the clamps and disconnect the hoses of the idle speed control valve 2 and crankcase ventilation 3.

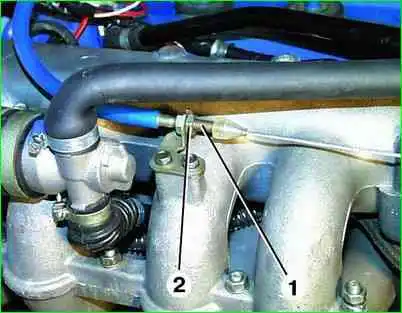

4. Loosen the clamps and disconnect the throttle heating hoses 1, having previously marked them.

Immediately plug the hoses with plugs to prevent loss of coolant.

Unscrew the four mounting bolts 2 and remove the throttle 3 with the gasket.

5. If it is necessary to remove the position sensor 2 throttle valve, unscrew the two screws 1 of its fastening.

Replacing the idle speed control valve

1. Disconnect the wire from the negative terminal of the battery.

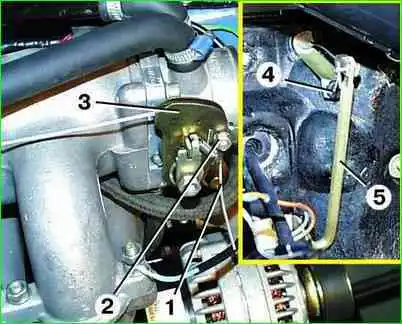

2. Loosen the clamps and disconnect hoses 1 and 2 from regulator 5. Disconnect the block with wires from connector 4 of the regulator.

Unscrew the two bolts 3 of the fastening and remove the regulator. Remove regulator 5 from clamp 6.

3. Install a new idle speed control valve in the reverse order.

Checking the idle speed control valve

- 1. Remove the idle speed control valve.

- 2. Apply a direct current of 12 V to the middle contact of the regulator connector and alternately to the side contacts

The valve should turn, opening or closing the inlet channel opening.

If this does not happen, then the regulator is faulty and needs to be replaced.

Replacing the injectors

- 1. Reduce the pressure in the fuel system if the engine has just been stopped.

- 2. Disconnect the wire from the negative terminal of the battery.

- 3. Remove the receiver.

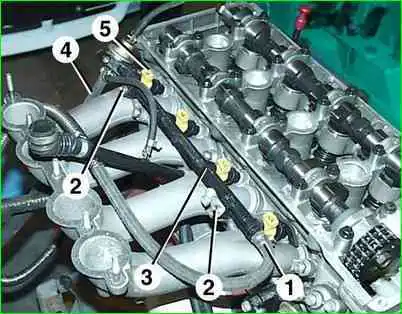

- 4. Loosen the clamps and disconnect the fuel supply hose 1 from the fuel line 3 of the engine. Disconnect the fuel drain hose 4 from the pressure reducing valve.

Disconnect the pads with wires from the connectors 5 of the four injectors.

5. IN Remove the injector from the engine fuel line. The injector is fixed in the fuel line hole only with the help of a sealing ring.

Unscrew the two bolts 2 of the fastening and carefully remove the fuel line 3 of the engine, removing the injectors from the holes in the intake pipe.

The injectors are fixed in the holes of the intake pipe only with the help of sealing rings.

6. Install a new injector in the reverse order.

Checking injectors

1. To check the tightness of the injector valve, lower the nozzle 1 into a container with gasoline or kerosene and supply compressed air under a pressure of 0.3 MPa (0.03 kgf/cm).

If air bubbles come out of the nozzle spray, then the injector valve is not tight and the injector must be replaced.

2. To check the serviceability of the injector solenoid winding, apply a direct current of 12 V to the injector connector. In this case, a characteristic click should be clearly heard, which indicates that the injector valve is opening.

If this does not happen, then the injector is faulty and must be replaced. This check can be carried out without removing the injector from the car.

3. The resistance of the injector solenoid winding can be checked with an ohmmeter by connecting it to the contacts of the injector connector. The resistance should be within 15.5-16 Ohms.

If the resistance value is not within the specified limits, replace the injector.

Replacing the pressure reducing valve

- 1. Reduce the pressure in the fuel system if the engine has just been stopped.

- 2. Disconnect the wire from the negative terminal of the battery.

- 3. Remove the engine fuel line.

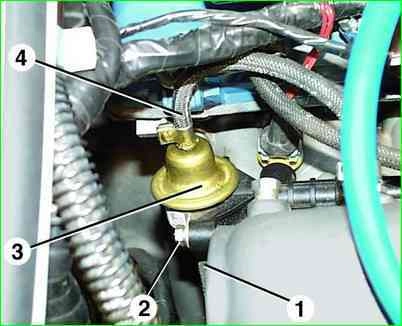

4. Disconnect the fuel drain hose 1 and vacuum hose 4 from the pressure reducing valve 3.

Unscrew the two mounting bolts 2 and remove the pressure reducing valve 3 from the engine fuel line.

5. Install the new valve in the reverse order.

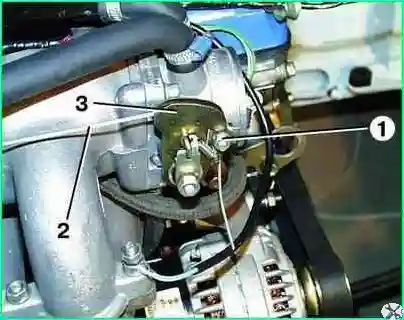

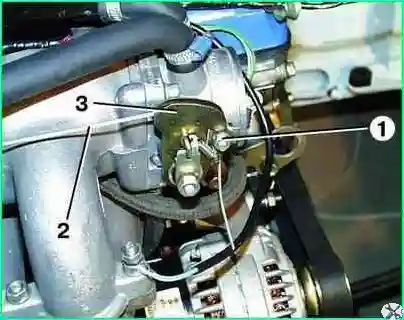

Replacing and checking the synchronization sensor

1. Disconnect the wire from the negative terminal of the battery.

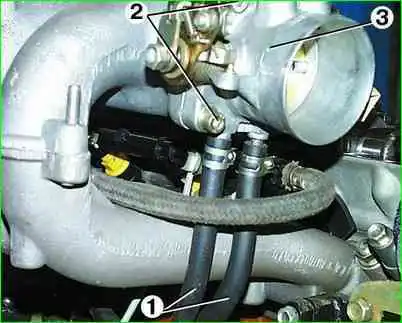

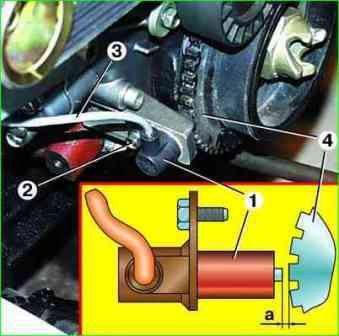

2. Disconnect the sensor wire connector 3, located behind the engine intake pipe.

Unscrew the mounting bolt 2 and remove sensor 1.

Check the resistance of the sensor coil with an ohmmeter, it should be within 850–900 Ohms.

If the resistance value is not within the specified limits, replace the sensor.

Install the sensor in the reverse order.

For normal operation of the sensor, the gap "a" between sensor 1 and synchronization disk 4 should be within 1.0–1.5 mm.