Replacing the front crankshaft seal

A sign that the front crankshaft oil seal needs to be replaced is oil leaking through its lip

Oil is sprayed out by the rotating crankshaft pulley, as a result of which the entire front part of the engine and engine compartment becomes oily.

Engine and transmission oils differ in smell, so with some skill you can determine which oil seal is defective.

There is another way to determine the type of oil.

Drop the oil into a thin layer of water poured into a vessel (or into a puddle).

The gear oil will spread over the entire surface of the water in the form of a rainbow film, and the motor oil will remain in the form of a drop, similar to a grain of lentil.

Before replacing the front crankshaft oil seal if a leak occurs, check the cleanliness of the engine crankcase ventilation system, since if it is clogged, the increased gas pressure in the crankcase causes a leak even with a working oil seal.

Withdrawal

Removing the radiator of the cooling system, article - "Radiator Gazelle"

Use a 36mm socket to unscrew the crankshaft pulley mounting bolt. We keep it from turning with a screwdriver inserted between the teeth.

Use two mounting blades to evenly press the crankshaft pulley away from the front cover of the cylinder block

Remove the pulley.

Sometimes the pulley is pressed in very tightly, so it is not possible to remove it with mounting blades. In this case, you will have to use a universal puller

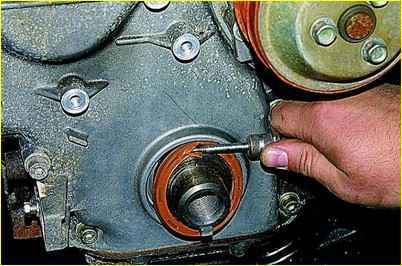

Use a screwdriver to remove the cuff.

Having filled two-thirds of the cavity between the working edge and the boot of the new cuff with Litol-24 lubricant, we press it into place, using the old cuff as a mandrel

Replacing the rear crankshaft seal

A sign that the crankshaft rear oil seal needs to be replaced is oil leaking through its lip.

Oil is sprayed by the rotating flywheel inside the clutch housing and then flows out through the cracks between the crankcase and its amplifier.

If there is a strong leak, the linings of the clutch driven disc may become oily and, as a result, the clutch may slip.

The reasons for oiling of the clutch discs and oil leakage from the clutch housing may be a leak in the gearbox input shaft oil seal.

Removing the gearbox (article – “Removing and installing the GAZ-2705 gearbox”

Removing the clutch housing, article - "Lever clutch GAZ-2705"

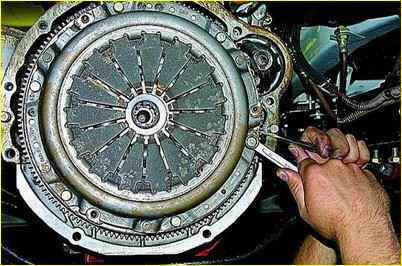

Using a 12mm wrench, unscrew the six bolts securing the clutch pressure plate, holding the flywheel from turning with a screwdriver inserted between its teeth.

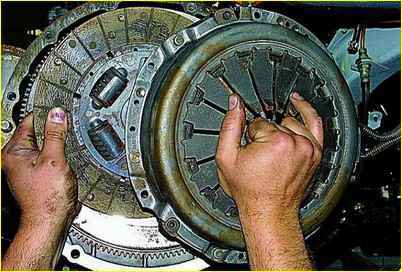

Remove the driven and pressure plates.

Using a 17mm socket, unscrew the six bolts securing the flywheel, holding it from turning with a screwdriver inserted between the teeth.

Remove the washer.

Remove the flywheel

Pry it with a screwdriver or pierce it with a beard and remove the cuff

Having filled two-thirds of the cavity between the working edge and the boot of the new cuff with Litol-24 lubricant, we press it into place, using the old cuff as a mandrel.

We install the removed components in the reverse order.