Removal, repair and installation of oil pump GAZ-2705

Drain the oil from the engine crankcase

Remove the oil sump

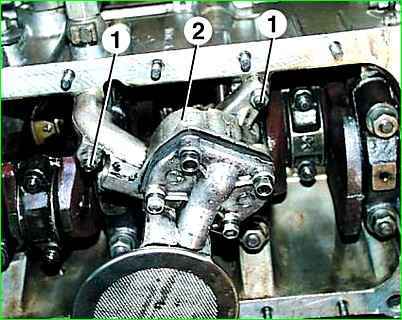

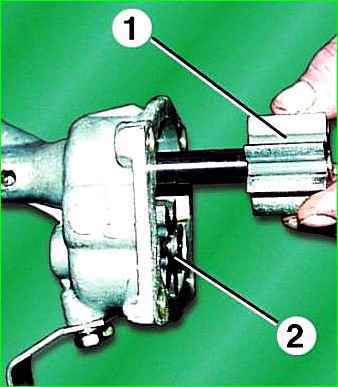

On the engine mod. 402 unscrew the two nuts 1 and remove the pump 2 with the receiver assembly.

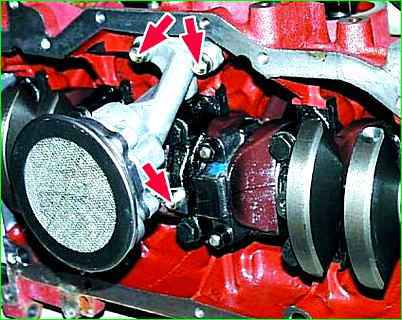

On the engine mod. 406, unscrew the three bolts and remove the pump and receiver assembly.

Disassembling the oil pump

Oil pumps for engines mod. 402 and 406 are similar in design.

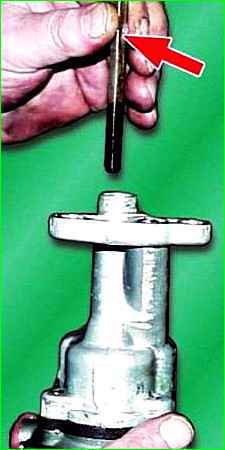

Remove the hex shaft of the oil pump drive.

Remove the mesh from the receiver by bending the edges of the mesh.

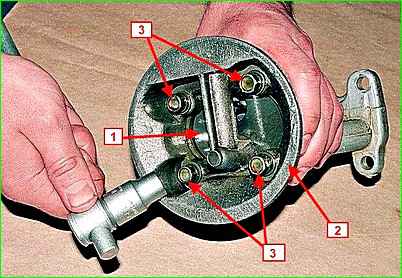

Unscrew four bolts 3 and remove receiver 2 and partition 1.

Remove drive gear 1 with shaft and driven gear 2.

If you need to remove the drive gear from the shaft, knock out the pin.

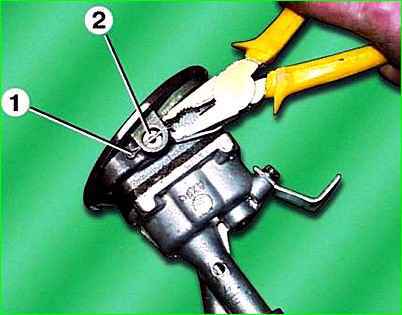

Remove cotter pin 1, washer 2, spring and pressure reducing valve plunger installed under washer 2.

Wash the pump parts with gasoline and blow with compressed air.

Inspection and repair of oil pump parts

If there is wear from the gears on the partition (cover for mod. 402), it must be sanded so that there are no traces of wear left.

Inspect the body. If it is very worn, the pump needs to be replaced.

The gears in the pump housing must rotate completely freely.

The plunger of the pressure reducing valve must move completely freely in the body.

Inspect the pressure reducing valve spring. If there are noticeable cracks or broken coils, replace the spring.

The length and stiffness of the spring are selected at the factory in such a way that the operation of the pressure reducing valve is optimal, therefore the length and stiffness of the spring cannot be changed in any way.

The free length of the spring should be 50 mm, the force to compress the spring by 10 mm should be 46 N (4.6 kgf) for an engine mod. 406.

For engine mod. 402, to compress the spring to a length of 40 mm, it is necessary to apply a force of 43.5-48.5 N (4.35-4.85 kgf).

If the spring does not meet at least one of these requirements, it must be replaced.

Assembling the oil pump

Assemble the pump in the reverse order.

When assembling the engine pump mod. 402, a cardboard gasket 0.3 mm thick must be placed under the pump cover.

It is prohibited to install a gasket of a different thickness or use sealant, paint, etc. when installing the gasket, as this will reduce the performance of the pump.

Install the pump in the reverse order of removal.

You can also see the article - “Oil pump ZMZ-406”