Checking the technical condition of the steering

Rotate the steering wheel to set the front wheels to the straight-ahead position

Place a screwdriver on the instrument panel with the tip facing the rim of the steering wheel at its top point.

Rotate the steering wheel in both directions until resistance appears (the wheels do not turn).

Using the tip of a screwdriver, mark the limits of free play of the steering wheel on the rim with chalk.

Using a tape measure, measure the distance along the wheel rim between the marks.

If the free play of the steering wheel is more than 90 mm (which corresponds to 25°) or 75 mm (20°) for buses, you must make sure that the increase in free play is not caused by wear of the steering rod joints and propeller shaft, or play in the front wheel bearings , as well as loosening the bipod nut, hinge pin nuts, propeller shaft wedges and other fasteners.

To do this, check the tightness of the steering nuts and bolts, and tighten them if necessary.

The ball joint and driveshaft nuts must be tightened and cottered.

When rotating the steering wheel, make sure there is no play in the ball joints of the rods.

We similarly check the play in the universal joints of the steering shaft.

We replace faulty parts with worn hinges.

If, after eliminating the above play, the free play exceeds the permissible norms, adjust the steering mechanism (see Removing the steering mechanism).

Add oil to the steering gear housing

Use a 12mm hex wrench to unscrew the plug

Use an oil syringe to add transmission oil to the lower edge of the filler hole

Wrap the plug in place.

Lubricating the joints of the propeller shaft

The joints of the propeller shaft are lubricated through grease nipples.

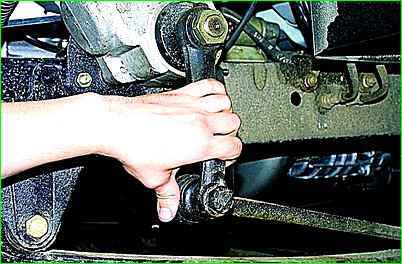

In the engine compartment, we clean three universal joints from dirt.

Use a syringe through the oiler valves to pump grease into each of the three joints until the grease is squeezed out of the seals.

If the oil does not come out somewhere, it means the lubrication channel of the oil can is clogged.

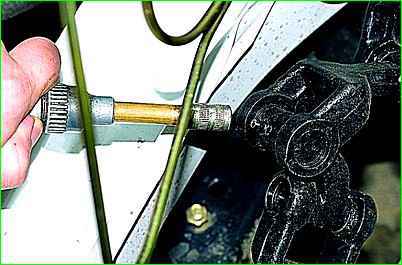

Then, use the “8” key to unscrew the grease nipple.

We wash it in kerosene and blow it with compressed air.

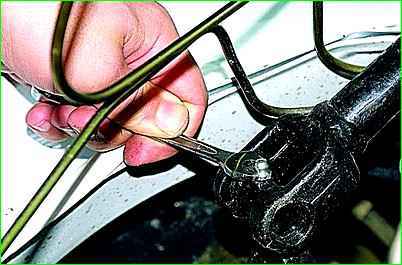

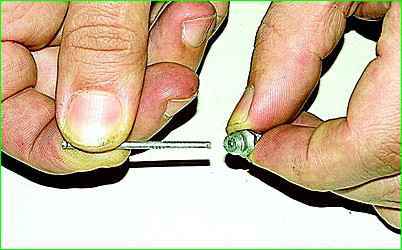

By pressing the valve ball with a thin rod, we make sure that it is movable and locks the oiler channel under the action of a spring.

We replace the faulty grease nipple.

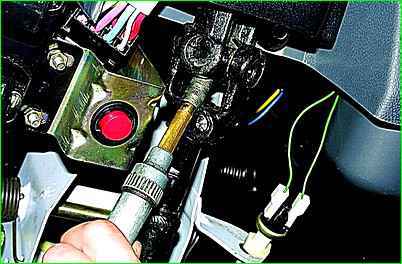

Lubricate the shaft joint located under the dashboard in the same way

For power steering, see the article - Changing the oil in the GAZ-2705 power steering