The YaMZ-6583.10 engine is designed for installation on onboard vehicles, chassis, truck tractors, dump trucks produced by KrAZ Holding Company

The YaMZ-6583.10 engine is structurally based on the YaMZ-7511.10 engine with individual cylinder heads and differs in technical characteristics due to the installation of electrically controlled fuel equipment with a Compact-40 type injection pump with an electronic regulator, changes in the design of a number of engine components and parts, with closed crankcase ventilation system.

The YaMZ-6583.10 engine meets the requirements of Euro-3 environmental standards.

Main parameters and characteristics of the YaMZ-6583.10 engine

Compression ratio - 17.5

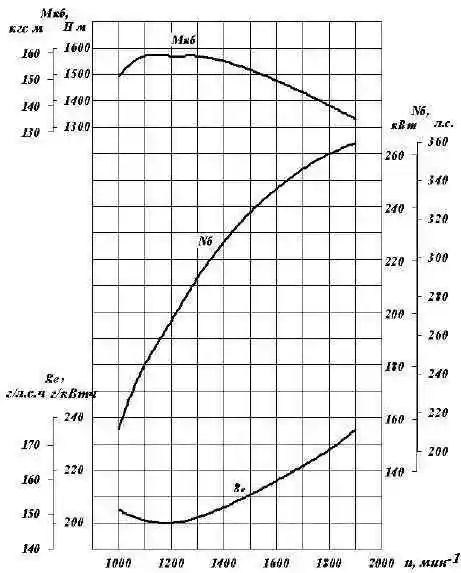

Rated power, kW (hp) - 264.7 (360)

Rated rotation speed, min -1 - 1900 −20+50

Maximum torque, Nm (kgf m) - 1569 (160)

Rotation speed at maximum torque, min -1 - 1100-1300

Idling speed, min -1:

- - maximum, no more than - 2150

- - minimum - 600±50

Specific fuel consumption according to speed characteristics, g/kW·h (g/hp·h):

− minimum, at a rotation speed of 1300±200, min -1 - 200 (147)

Relative oil consumption for waste in % to fuel consumption, no more than - 0.1

Speed characteristic

Injection pump model with electronic control system (ECS) - 179.1111002-30

Injection pump model without ESU - 179.1111005

Nozzle - 51.1112010-21

Speed controller (rotation speed) - Electronic ESU-1A

Setting angle of fuel injection advance, degrees 2+1

Electronic control unit (ECU) with microprocessor software - 179.3763001-30

Electronic control system sensors:

- − synchronization (rotation speed) - Induction DS-1

- − charge air pressure - 23.3855

- − position of the actuator (fuel injection pump rack) - 36.3855-20

- − temperatures - 233.3828

- − fuel temperature - 192.3828

- − pedal module - KDBA 453621.003

Electrical harness - Attached to the engine

Turbocompressor - TKR 100

Crankcase ventilation system - closed type with suction into the air intake system in front of the TKR, with an oil separator and a pressure control valve

The fan is eight-blade, 660 mm in diameter, with a gear drive and a friction clutch for automatic and manual fan activation.

Automatic switching temperature is not less than 85°C. Drive ratio – 1.31

Emergency stop air damper (solenoid installed in the intake manifold after the charge air cooler) - Solenoid driven (manually operated)

Generator - alternating current, with a V-belt drive, with a rated voltage of 28 V.

Gear ratio of the generator drive - 3.67

Model 7762.01-03 with a maximum load current of 80 A

Starter - Model AZF 4581, Iskra (Slovenia), voltage 24 V

Clutch

To complete engines without a gearbox, clutch hub splines according to SAE (two inches) - Model YaMZ-184-15

Gearbox - Model YaMZ-2391-20

Filling volumes, l:

- − engine lubrication system - 32

- − engine cooling system (without water radiator volume) - 22

Weight of the unfuelled power unit as supplied, kg:

- − without clutch and gearbox - 1250

- − with clutch and gearbox - 1660