Usually, the oil deflector caps are changed when there is an increased oil consumption, accompanied by a large emission of smoke from the muffler

And also when the engine overheats, when the valve seals lose the required elasticity.

We set the crankshaft to the TDC position of the pistons of the 1st and 4th cylinders (see "Checking the condition and replacing the timing belt").

In this position of the shaft, we change the oil deflector caps of the valves of the 1st and 4th cylinders.

We remove the camshaft (see "Removing the camshaft").

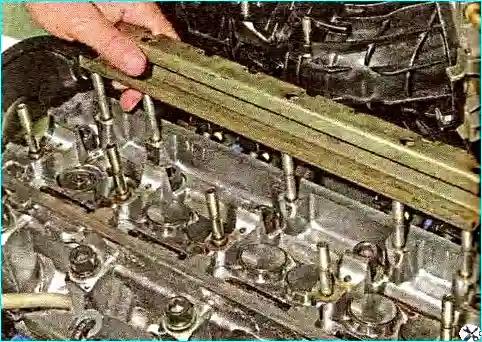

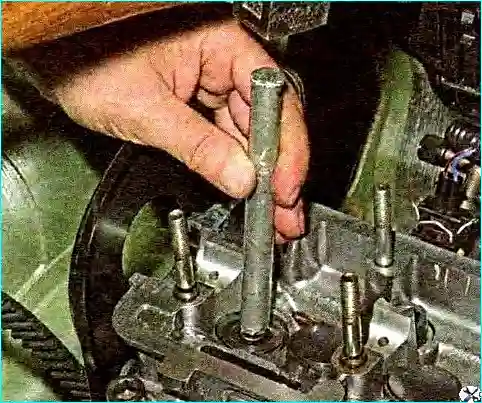

We take out the pusher with the adjusting washer from the cylinder head socket.

We unscrew the spark plug of the 1st cylinder and insert a rod of soft metal (about 8 mm in diameter) through the spark plug hole between the piston bottom and the valve plate, on which we change cap.

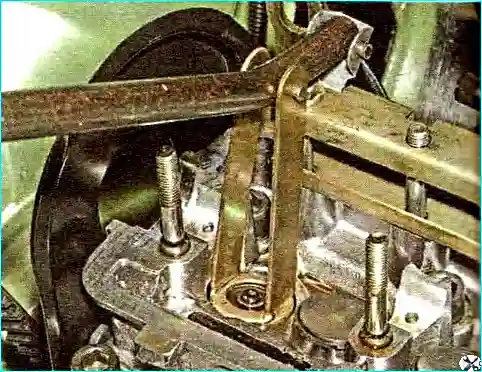

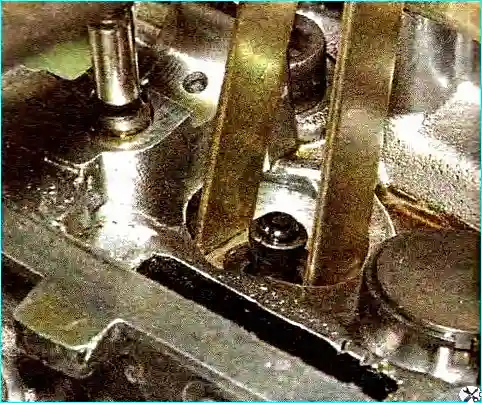

We install the valve spring compressor bar on the cylinder head studs and fasten it with nuts to the outer studs.

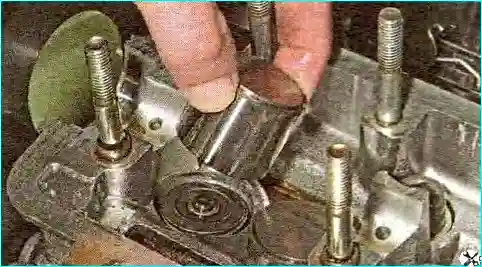

Install the valve spring compressor.

Put the valve spring compressor thrust pad against the valve plate and insert the engagement lever into the groove located on the rear side of the bar.

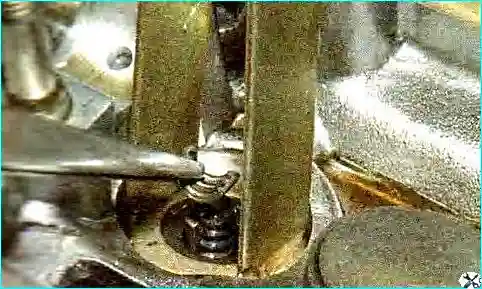

Press the valve spring compressor lever and compress the springs

Removing crackers with tweezers.

Removing the plate with springs

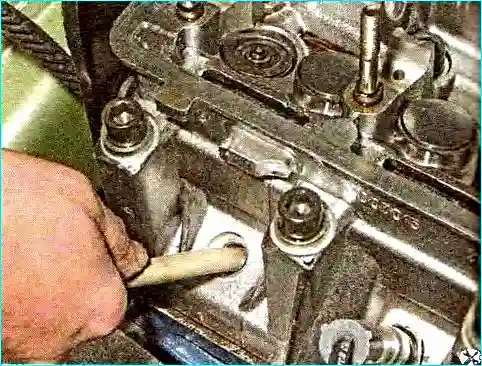

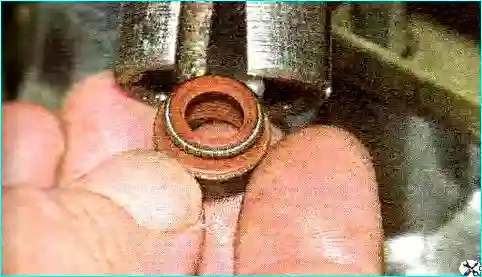

Using special pliers or a device for dismantling caps, remove the oil seal from the valve guide sleeve

Remove the cap from pliers

Apply a layer of engine oil to the working edge of the new cap and install the cap on the valve stem

Using a mandrel, press the cap onto the valve guide sleeve.

You can use a 12 mm high head as a mandrel.

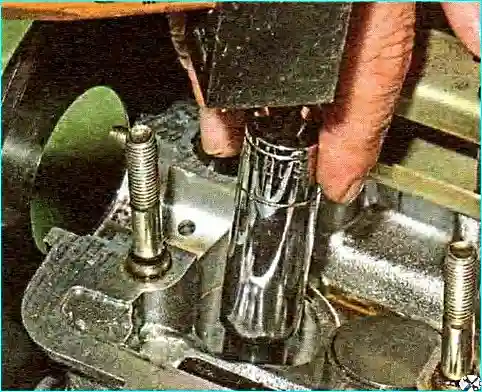

Assemble the valve mechanism in the reverse order.

Remove the rod from the spark plug hole.

After assembling the valve mechanism, strike the end of the valve with a hammer through a soft metal mandrel so that the crackers are securely fixed in the grooves of the valve stem.

Lubricate the pusher and the adjusting washer of the valve with engine oil and install it in the cylinder head socket.

Then repeat these operations for the other valve of the 1st cylinder and then for both valves of the 4th cylinder.

After that, turning the crankshaft by 180° (TDC of the pistons of the 2nd and 3rd cylinders), similarly change the oil deflector caps of the valves of the 2nd and 3rd cylinders.

Assemble the valve mechanism in the reverse order.