Remove the cylinder head cover (see “Adjusting thermal clearances in the engine valve mechanism”).

Disconnect the engine management system wiring harness block from the phase sensor and coolant temperature sensor.

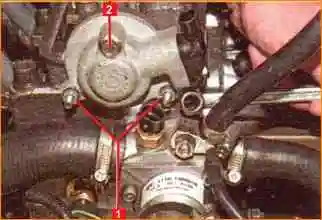

Using a 10mm wrench, unscrew two nuts 1 and one bolt 2 securing the cylinder head plug.

There is a rubber O-ring under the bolt head.

Remove the cylinder head plug along with the sensor.

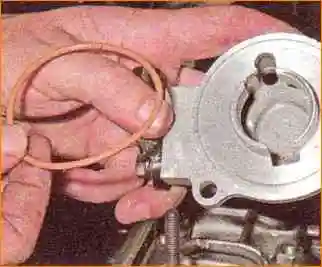

A rubber sealing ring is installed in the groove of the plug flange.

Remove the camshaft timing pulley.

Using a 13 key, evenly in several steps (until the pressure of the valve springs is removed), unscrew the ten nuts securing the camshaft bearing housings.

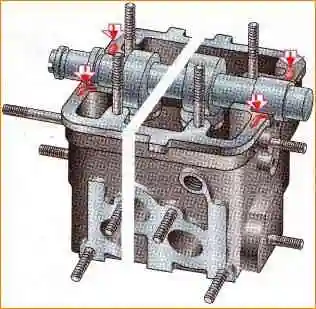

Remove both camshaft bearing housings from the studs

Having slightly moved the rear timing belt cover away from the cylinder head, remove the camshaft.

Remove the oil seal from the camshaft toe.

Install the camshaft in the following sequence.

We clean the mating surfaces of the cylinder head and bearing housings from old sealant and oil.

Lubricate the camshaft bearing journals and cams with engine oil.

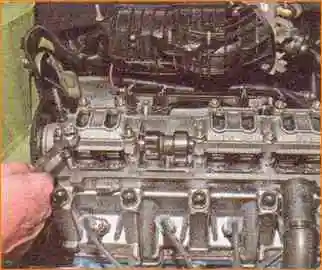

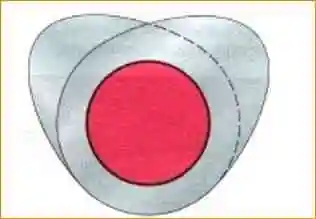

We place the shaft in the cylinder head supports so that the cams of the first cylinder are directed upward (see Fig. 8).

In this case, the pistons of the 1st and 4th cylinders must be at TDC.

On the surfaces of the cylinder head, mating with the bearing housings in the area of the outer supports, apply a thin layer of silicone sealant (see Fig. 9).

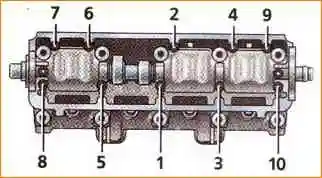

Install the bearing housings and tighten the nuts securing them in two steps.

Pre-tighten the nuts in the sequence shown in Fig. 10, until the surfaces of the bearing housings touch the cylinder head.

In this case, it is necessary to ensure that the installation sleeves of the housings fit freely into their sockets.

Finally tighten the nuts to a torque of 21 - 25 Nm in the same sequence.

After tightening the nuts, carefully remove any remaining sealant squeezed out of the gaps.

Check the clearances in the valve mechanism.

Press in a new camshaft oil seal (see “Replacing the oil seal camshaft").

We carry out further assembly in reverse order.