Before installing the oil pump, check the ease of rotation of the gears

The gears of the assembled pump should rotate freely by hand, without jamming or jerking

The guide pins of the oil pump should fit tightly into the holes in the first main bearing cap.

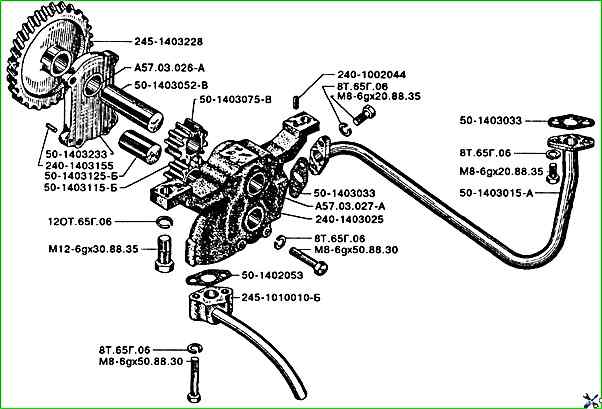

Parts of the D-245 oil pump according to the catalog: 120T.65G.06 Washer; 240-1002044 Pin; 240-1403020 Housing with bushing assembly; 240-1403025 Housing; 240-1403150 Cover with bushing assembly; 240-1403155 Cover; 245-1010010-B Oil receiver; 245-1403010 Oil pump; 245-1403228 Gear; 50-1402053 Gasket; 50-1403015-A Branch pipe; 50-1403033 Gasket; 50-1403052-B Roller; 50-1403075-B Gear; 50-1403115-B Gear; 50-1403125-B Pin; 50-1403233 Pin; 8T.65G.06 Washer; A57.03.026-A Bushing; A57.03.027-A Bushing; A57.03.028-A Bushing; М12-6gх30.88.35 Bolt; М8-6gх20.88.35 Bolt; М8-6gх50.88.35 Bolt

Locking washers must be placed under the oil pump mounting bolts.

The lateral clearance between the teeth of the oil pump drive gears must be within 0.1-0.65 mm.

The lateral clearance between the teeth of the hydraulic pump drive gear wheels must be within 0.08-0.20 mm.

The hydraulic pump drive housing must be covered with a cover and gasket after installation on the diesel engine.

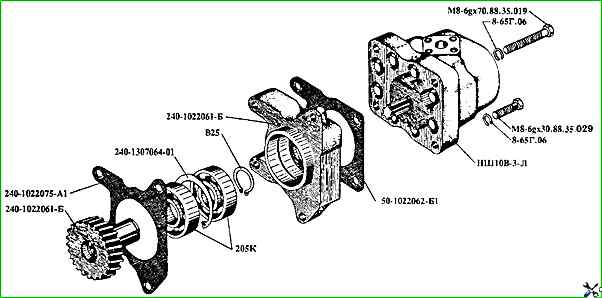

ZIL-5301 power steering pump parts according to the catalog: 205K Bearing; 240-1022030-02 Hydraulic pump drive assembly; 240-1022061-B Gear; 240-1022069 Housing; 240-1022075-A1 Gasket; 240-1307064-01 Ring; 50-1022062-B1 Gasket; 8.65G.06 Washer; B25 Ring; М8-6gх30.88.35.019 Bolt; М8-6gх70.88.35.019 Bolt; НШ10В-3-Л Gear pump

The oil pump received for diesel assembly must be run-in and tested.

The bolts securing the outlet pipe to the oil pump and cylinder block must be tightened to a torque of 15-25 Nm.

The power steering pump housing must be washed and blown out with compressed air before installation.

Installing the oil receiver

Before installation, the oil receiver must pass a hydraulic test with diesel fuel or an air test under a pressure of 0.1±0.02 MPa.

Air leaks, drips or seepage at the junction of the pipe and flange are not allowed.

Bumps and irregularities after welding must be cleaned.

Installing the oil pan

Seals must be installed in the grooves of the oil pan support before assembly.

Before installing the oil pan, trim the protruding ends of the gasket between the distribution cover and the block plane.

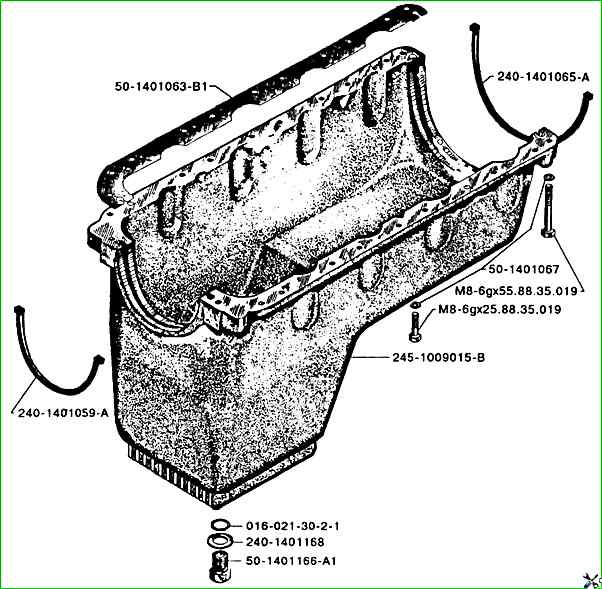

Parts of the oil pan of the D-245 diesel engine according to the spare parts catalog: 016-021-30-2-1 – Ring; 240-1401059-A - Front oil seal; 240-1401065-A Oil seal; 240-1401168 Washer; 245-1009015-B Oil pan; 245-1009015-B Oil pan; 50-1401063-B1 Gasket; 50-1401067 Washer; 50-1401166-A1 Plug; М8-6gх25.88.35.019 Bolt; М8-6gх55.88.35.019 Bolt

The plane of contact of the oil pan to the block must be lubricated in three places with UZOM paste GOST 13489-79 before installing the gasket.

Narratives and dents wider than 0.1 mm on the machined surfaces of the oil pan are not allowed.