Clutch - single-plate, dry, with a central diaphragm-type pressure spring

It is located in an aluminum crankcase, bolted to the engine block and structurally integrated with the gearbox.

Clutch drive – hydraulic.

The clutch housing is connected to the flywheel with six bolts.

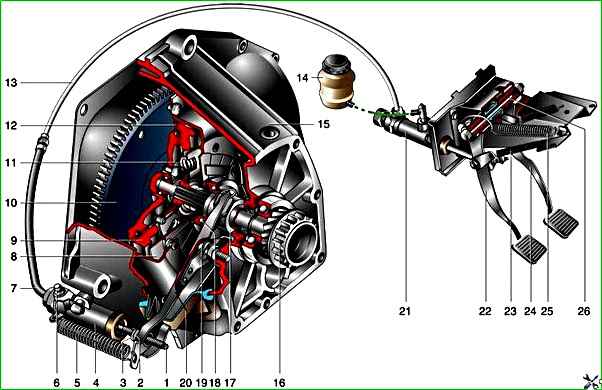

Clutch and its hydraulic drive: 1 - clutch release fork pusher; 2 - adjusting nut; 3 - lock nut; 4 - working cylinder of the hydraulic clutch release; 5 - fork release spring; 6 - bleeder fitting; 7 - flexible hose for hydraulic clutch; 8 - central pressure diaphragm spring; 9 - pressure disk; 10 - flywheel; 11 - damper spring; 12 - driven disk; 13 - pipeline; 14 - hydraulic drive reservoir; 15 - clutch housing; 16 - gearbox input shaft; 17 - clutch release bearing clutch; 18 - clutch release bearing; 19 - ball support for clutch release fork; 20 - clutch release fork; 21 - master cylinder of the clutch release drive; 22 - clutch pedal; 23 - clutch pedal release spring; 24 - brake pedal; 25 - servo spring; 26 - pedal axis

The flywheel has three pins, which, when installed, fit into the corresponding holes in the casing, centering it.

The casing is connected to the pressure plate by three pairs of elastic steel plates with rivets.

The other three plates connect the casing to a thrust flange facing the clutch release bearing (“release” bearing).

This assembly (“clutch basket”) is balanced on a stand, so it should be replaced as a whole.

Replacement is necessary if the surface of the pressure plate is severely worn or the spring is “settled.”

The driven disk assembly with the spring torsional vibration damper is installed between the flywheel and the clutch housing and can move along the splines of the transmission input shaft.

The disk is replaced if there is more than 0.5 mm of runout in the area of the linings, cracking, scuffing or uneven wear, as well as if the distance from the surface of the lining to the rivets is less than 0.2 mm.

The clutch release bearing is mounted on a clutch, which, when the clutch is turned on and off, moves along the guide sleeve, acting on the thrust flange of the diaphragm spring.

When the clutch is disengaged, there must be a gap between the bearing and the thrust flange, which is determined by the free movement of the clutch release fork pusher (see How to adjust the VAZ-2121 clutch drive).

The bearing does not require maintenance or lubrication. It is replaced in case of increased noise when the clutch is engaged.

The clutch release fork is stamped steel, located in the clutch housing and swings on a ball joint (there is a recess stamped on the fork for it).

The fork is pressed against the ball joint by a leaf spring (riveted in the middle part of the fork).

The ends of the fork rest against the clutch release bearing coupling and are pressed against it by a figured spring.

The hole for the clutch fork in the housing is covered with a rubber corrugated cover.

The fork is constantly pressed against the pusher of the working cylinder by a tension spring.

The clutch pedal is suspended on an axle in a bracket.

To ease the effort when engaging the clutch, a servo spring is attached to its upper end.

To ensure that the pedal returns to its original position, a return spring (weaker) is used.

The pedal is pivotally connected to a pusher, which fits into the recess of the clutch master cylinder piston.

The master cylinder is secured in the engine compartment on two studs welded to the pedal bracket.

The master cylinder is connected by a steel tube and rubber hose to the slave cylinder, secured to the clutch housing with two bolts.

When you press the pedal, the piston of the master cylinder compresses the fluid, the piston of the working cylinder extends and acts through the pusher on the clutch release fork.

When the pedal is released, the fork, under the action of the release spring, presses on the pusher, returning the pistons to their original position.

The clutch hydraulic drive uses DOT-3 or DOT-4 brake fluid.

Its reserve is located in a tank connected to the main cylinder with a rubber hose.

Under the tank lid there is a rubber corrugated diaphragm that isolates the tank cavity from atmospheric moisture and dust.

For bleeding the hydraulic drive (when replacing its parts or changing the fluid), a fitting is provided on the working cylinder.

Diagnosis of clutch faults

Cause of malfunction - Method of elimination

Clutch slips (does not fully engage)

When you press the accelerator pedal sharply, the engine gains speed, but the car hardly accelerates (this is especially noticeable when driving to rise); the smell of overheated friction linings may be felt; fuel consumption increases:

- - Incorrect clutch drive adjustment (no pedal free play) - Adjust the drive

- - Oiling of the flywheel, pressure plate, friction linings of the driven disk - Thoroughly rinse the oily surfaces with white spirit or gasoline and wipe them dry. Replace the heavily oiled driven disk. Eliminate the cause of oiling (oil leakage through the engine and/or gearbox seal)

- - Severe wear or burning of the friction linings of the driven disk - Replace the driven disk

- - Reduced diaphragm spring force - Replace the pressure plate with the housing (“clutch basket”)

- - Seizing of the driven disk hub on the splines of the input shaft of the gearbox - Clean the splines from dirt, remove minor damage with a file.

If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply Litol-24 or CV joint lubricant to the splines

- - The compensation hole of the clutch master cylinder is clogged - Disassemble the master cylinder, rinse and clean the parts. Replace its seals and hydraulic fluid

- - The clutch master cylinder piston returns slowly to its original position due to swelling of the rubber cuffs - Replace the cuffs or cylinder assembly. If you suspect gasoline or other solvents have gotten into the clutch fluid, replace it

Clutch moves (does not disengage completely)

It is difficult to change forward gears, reverse gear is engaged with noise:

- - Incorrect adjustment of the clutch drive (full pedal travel is small, its free play is increased) - Adjust the drive

- - Air has entered the hydraulic drive system (the pedal is “soft”) - Bleed the system, tighten the connections. If there is a leak from the master or slave cylinders, replace their cuffs or cylinder assemblies

- - The clutch release fork is deformed - Replace the fork

- - Loose rivets or breakage of friction linings, warping of the driven disk (end runout more than 0.5 mm) - Replace the disk

- - Severe and uneven wear, scoring on the working surfaces of the flywheel or pressure plate - Grind or replace the flywheel. If the surface of the pressure plate is damaged, replace the housing with the pressure plate assembly (“clutch basket”)

- - Distortion or warping of the pressure plate - Replace the housing with the pressure plate assembly (“clutch basket”)

- - Seizing of the driven disk hub on the splines of the input shaft of the gearbox - Clean the splines from dirt, remove minor damage with a file.

If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply fresh lubricant Litol-24 or CV joint-4 to the splines

- - Loosening of the rivets of the connecting plates of the clutch housing or diaphragm spring, breakage of the plates - Replace the housing with the pressure plate assembly (“clutch basket”)

- - Release bearing jammed - Replace bearing

The clutch does not disengage (the pedal “falls through”):

- - The clutch release fork is severely deformed or broken - Replace the fork

- - Air in the hydraulic drive system - Bleed the system, tighten the connections. If there is a leak from the master or slave cylinders, replace the cylinder assemblies

The clutch does not disengage (the pedal “falls through”)

The clutch can only be engaged briefly by sharply pressing the pedal:

- - Heavy wear, defects in the master cylinder mirror; dirt in the cylinder - Replace the cylinder

- - Worn or defective master cylinder cuff - Replace the cylinder assembly

Jerking when starting off:

- Seizing of the driven disk hub on the splines of the input shaft of the gearbox - Clean the splines from dirt, remove minor damage with a file.

If the splines are significantly worn or damaged, replace the transmission disc and/or input shaft. Before assembly, apply CV joint-4 or Litol-24 lubricant to the splines

- - Deformation of the driven disk - Replace the driven disk

- - Loose fastening of the friction linings of the driven disk, severe wear or cracks on the linings - Replace the driven disk

- - Loss of elasticity of the spring plates of the driven disk - Replace the driven disk

- - Significant settlement or breakage of the torsional vibration damper springs, wear of the windows for the springs - Replace the driven disk

- - Scores on the working surfaces of the flywheel or pressure plate - Grind or replace the flywheel or clutch housing with pressure plate assembly (“clutch basket”)

Rattling, knocking or noise when engaging the clutch:

- - Significant settlement or breakage of the torsional vibration damper springs, wear of the windows for the springs - Replace the driven disk

- - Deformation of the driven disk - Replace the driven disk

- - Loosening fastened Friction linings of the driven disk are worn out, severe wear or cracks on the linings - Replace the driven disk

Uniform noise when the clutch is disengaged:

- - The release bearing is worn out or lacks lubrication - Replace the bearing

- - Worn front bearing of the gearbox input shaft (at the end of the crankshaft) or lack of lubrication - Replace the bearing

Clutch pedal squeaking:

- - Plastic pedal bushings are not lubricated - Lubricate the bushings with Litol-24 or CV joint-4

- - The plastic bushings of the pedal are heavily worn - Replace the bushings, before installation, lubricate them with Litol-24 or CV joint-4

After releasing the clutch pedal, it does not return to its original position:

- - Air in the hydraulic drive system - Bleed the system, tighten connections

- - The return spring of the pedal and/or clutch fork has lost elasticity or is broken - Replace the spring(s)