The K-126 carburetor is installed on GAZ-21, GAZ-24, GAZ-53, GAZ-66 engines, etc.

A very simple and reliable carburetor

A special feature of the K-126B carburetor is that all jets can be washed and blown out without disassembling the carburetor

The carburetor has two mixing chambers: primary and secondary. The primary chamber operates in all engine modes.

The secondary chamber comes into operation under heavy load (approximately after ⅔ of the primary chamber throttle stroke).

To ensure uninterrupted engine operation in all modes, the carburetor has the following metering devices: a cold running system of the primary chamber, a transition system of the secondary chamber, the main metering systems of the primary and secondary chambers, an economizer system, a cold engine starting system and an accelerator pump system.

All elements of the metering systems are located in the body of the float chamber, its cover and the body of the mixing chambers.

The body and cover of the float chamber are cast from zinc alloy.

The body of the mixing chambers is cast from aluminum alloy.

Sealing cardboard gaskets.

The float chamber housing contains: two large 6 and two small diffusers 7, two main fuel jets 28, two air brake jets 21 of the main metering systems, two emulsion tubes and, located in the wells, fuel 13 and air jets of the idle system, economizer and guide sleeve 27, accelerator pump 24 with discharge and check valves.

The sprayers of the main metering systems are brought out into small diffusers of the primary and secondary chambers.

The diffusers are pressed into the float chamber housing, in the float chamber housing there is a window 15 for monitoring the fuel level and the operation of the float mechanism.

All jet channels are equipped with plugs to ensure access to them without disassembling carburetor.

The idle fuel jet can be turned outward, for which its body is brought out through the cover upwards.

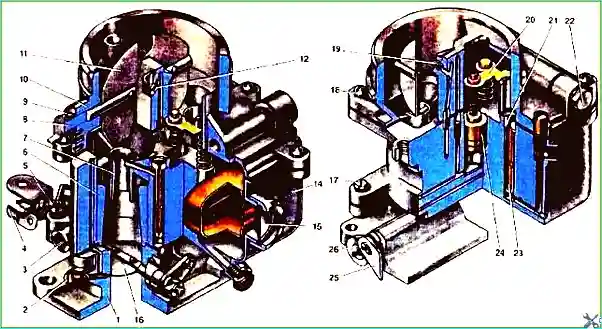

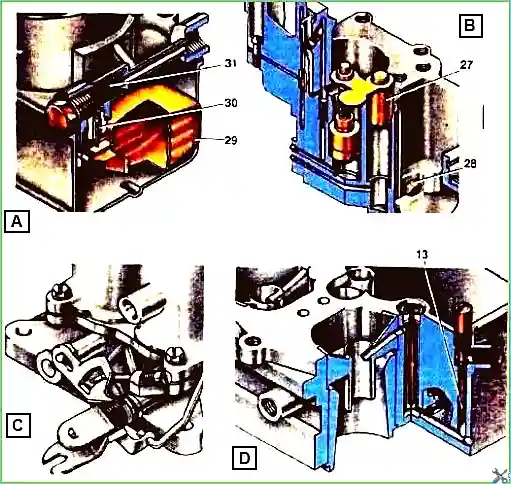

Fig. 1. K-126 Carburetor: 1 - Mixing chamber; 2 - Mixture quality screw; 3 - Vacuum regulator hole; 4 - Throttle drive lever; 5 - Mixture quantity screw; 6 - Large diffuser; 7 - Small diffuser; 8 - Air damper shaft; 9 - Air damper spring; 10 - Float chamber cover; 11. Air damper; 12 - Accelerator pump nozzle. 13. Idle fuel jet; 14 - Float chamber housing; 15 - Inspection window; 16 - Throttle valve; 17 - Housing fastening screw; 18 - Cover fastening screw; 19 - Economizer nozzle; 20 - Accelerator pump drive. 21 - Main air jet; 22 - Filter plug; 23. Emulsion tube; 24 - Accelerator pump piston; 25 - Drive linkage; 26 - Secondary throttle valve shaft; 27 - Guide sleeve; 28 - Main fuel jet; 29 - Float; 30 - Fuel valve; 31 - Fuel filter

Fig. 2. K-126 carburetor: A - float chamber; B - accelerator pump; C - secondary throttle valve drive of the carburetor; D - fuel jets

The air damper 11 with a semi-automatic drive is located in the cover of the float chamber.

The air damper drive is connected to the primary chamber throttle shaft by a system of levers and rods, which, when starting a cold engine, open the throttle valve to an angle necessary to maintain the starting engine speed.

The secondary throttle valve is tightly closed.

This system consists of an air damper drive lever, which acts with one arm on the air damper shaft lever, and with the other through a rod on the low gas lever, which, turning, presses the primary chamber damper and opens it.

A float mechanism is attached to the carburetor cover, which consists of a float suspended on an axis and a valve 30 fuel supply.

The carburetor float is made of 0.2 mm thick sheet brass.

The fuel supply valve is detachable and consists of a housing and a shut-off needle.

The valve seat diameter is 2.2 mm. The needle cone has a special sealing washer made of a fluorine rubber-based compound.

The fuel entering the float chamber passes through a mesh filter 31.

The mixing chamber housing contains two throttle valves 16 of the primary chamber and the secondary chamber, an adjusting screw 2 of the idle system, in toxicity int, idle system channels serving to ensure coordinated operation of the idle system and the main metering system of the primary chamber, hole 3 for supplying vacuum to the ignition advance vacuum regulator, as well as the transition system of the secondary chamber.

The carburetor idle system consists of a fuel jet 13, an air jet and two holes in the primary mixing chamber (upper and lower).

The lower hole is equipped with a screw 2 for adjusting the composition of the combustible mixture.

The idle fuel jet is located under the fuel level and is connected after the main jet of the primary chamber.

The fuel emulsification is performed by the air jet.

The required performance of the system is achieved by the idle fuel jet, the air brake jet, as well as the size and location of the transition holes in the primary mixing chamber.

The main metering system of each chamber consists of large and small diffusers, emulsion tubes, main fuel and main air jets.

The main air jet 21 regulates the air flow into the emulsion tube 23, located in the emulsion well.

The emulsion tube has special holes designed to obtain the required operating characteristics of the system.

The idle system and the main metering system of the primary chamber provide the required fuel consumption in all main engine operating modes.

The economizer system consists of a guide sleeve 27, valve 23 and sprayer 19.

The economizer system is activated before the secondary chamber throttle valve is fully opened.

It should be noted that in full load mode, in addition to the system, the following operate: economizer, the main metering systems of both chambers and very little fuel continues to flow through the idle system.

The accelerator pump system consists of a piston 24, a drive mechanism 20 of the inlet and discharge (outlet) valves and a sprayer 12, brought out into the air branch pipe of the primary chamber.

The system has a drive from the axis of the throttle of the primary chamber and operates during acceleration of the car.

The lever 4 of the drive is rigidly fixed on the axis of the throttle valve of the primary chamber. The linkage 25 is also rigidly fixed to the axis.

The linkage is freely mounted on the axis of the damper 16 and has two grooves.

The linkage moves in the first of them, and the pin with the roller of the lever 26 of the secondary damper axis 8 drive fixed to it in the second one.

The dampers are held in the closed position by springs fixed to the axis of the primary chamber and the axis of the secondary chamber.

The linkage 25 also constantly tends to close the secondary chamber damper, since it is acted upon by the return spring fixed to the axis of the primary chamber.

When the lever 4 of the primary chamber axis drive moves, the linkage of the primary chamber lever first moves freely in the groove of the linkage 25 (thus, only the primary chamber damper opens), and after about 2/3 of its travel, the linkage begins to turn it.

Linkage 25 secondary throttle actuator opens the secondary throttle valve. When the gas is released, the springs return the entire lever system to its original position.

The carburetor must be washed in clean unleaded gasoline or acetone, followed by blowing with compressed air.

Condition of the main parts and units arriving for assembly

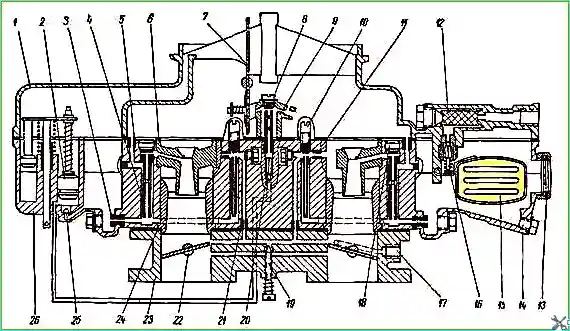

Fig. 3. K126 carburetor diagram: 1 - upper part of the carburetor; 2 - accelerator pump piston; 3 - main fuel jet; 4 - emulsion tube; 5 - main system air jet; 6 - small diffuser with sprayer; 7 - air damper; 8 - fuel supply screw; 9 - accelerator pump nozzle; 10 - idle fuel jet; 11 - idle air jet; 12 - fuel filter; 13 - inspection window; 14 - drain plug; 15 - float; 16 - fuel valve; 17 - outlet for vacuum corrector; 18 - plug; 19 - idle adjusting screw; 20 - accelerator pump outlet valve; 21 - idle emulsion jet; 22 - throttle valve; 23 - mixing chamber housing; 24 - large diffuser; 25 - accelerator pump inlet valve; 26 - middle section of the carburetor (float chamber body and middle section of the air jets)

All channels of the body parts must be thoroughly washed and blown out with compressed air.

Repair of broken fastening flanges that do not cover internal cavities and channels is allowed by welding.

The surfaces of the connecting flanges of the body parts must be flat without nicks and irregularities.

When checking on the plate, the non-flatness must not exceed 0.1 mm.

Jet performance before installation in the carburetor, it must be checked on the NIIAT-528 model device or another device that allows you to check the performance of the jets:

- - main air jet Ø 0.8+0.06 mm;

- - idle fuel jet Ø 0.75+0.06 mm;

- - idle air jet Ø 1.5+0.06 mm;

- - economizer nozzle Ø 0.7+0.06 mm;

- - accelerator pump nozzle Ø 0.6+0.05 mm.

The performance value of the K-126B carburetor jets must be within the following limits:

- - jet fuel main — 340 ± 4.5 cm 3 / min;

- - diaphragm mechanism jet — 75 ± 3 cm 3 / min;

- - vacuum diaphragm mechanism jet — 310 ± 7 cm 3 / min.

Size of emulsion holes in the mixing chamber:

- - upper Ø 1.0 + 0.06 ;

- - lower Ø 1.3 + 0.06 mm.

The threads of the jets must not have nicks.

The economizer valve must be tight. The tightness must be checked with water under a pressure of 1200 mm H2O. water flow under the valve is allowed at a rate of no more than 4 drops per minute.

The valve stem must protrude from the body within 1.1+0.3 mm.

The diffuser body must be intact, without breaks or cracks.

The float must not have any holes or dents. It must be checked for leaks by immersion in hot water. The appearance of air bubbles in a serviceable float is not allowed.

The weight of the float must be within 13.3 ± 0.7 g.

The fuel supply valve must be tested for leaks with a vacuum of 100 mm Hg through water; in this case, no more than 10 drops per minute are allowed to leak.

Disassembling the carburetor

The carburetor is disassembled to clean the float chamber, change the jets and mating parts if their fits are damaged.

Disassemble the carburetor in the following order:

- - unfasten the cotter pin and remove one end of the low-speed rod from the lever hole;

- - unscrew the seven screws securing the float chamber cover, remove the cover, being careful not to damage the cardboard gasket underneath;

- - remove the float axis and remove the float. Remove the fuel valve needle together with the spring;

unscrew the fuel valve body together with the paronite gasket. It is not recommended to remove the air damper unless necessary.

To remove the damper, unscrew the two screws that secure it, then unscrew the screw that secures the drive lever bushing, remove the lever together with the bushing and spring.

Remove the air damper shaft together with the lever and return spring.

- - unscrew the filter plug, release the paronite gasket and remove the mesh filter;

- - then proceed to disassembling the float chamber. Remove the cotter pin from the accelerator pump drive earring.

Carefully holding the accelerator pump drive with your hand from above, release the drive rod from the lever fixed on the throttle shaft, remove the earring.

Remove the accelerator pump drive rod assembled with the piston and economizer drive from the carburetor body.

It is not recommended to disassemble the accelerator pump drive. If it is necessary to replace the piston of the accelerator pump or for other reasons, unscrew the mounting nuts of the rods of the accelerator pump and economizer and remove the rods, removing the springs;

- - unscrew the plugs on the outside of the housing, unscrew the main fuel jets of the primary and secondary chambers and the idle air jet;

- - to access the emulsion tubes, unscrew the main air jets of the primary and secondary chambers.

- - unscrew the idle fuel jet and the economizer valve. Remove the accelerator pump discharge valve;

- - unscrew the large nut in the front part of the housing and carefully, so as not to damage the gasket, remove the sight glass of the float chamber;

- - it is not allowed to press out small diffusers from the carburetor housing;

- - unscrew the four fastening screws and disconnect the mixing chamber from the float chamber. Remove the two large diffusers and the gasket between the chambers.

- - Do not disassemble the mixing chamber unless necessary. If the throttle shaft wobbles in the bosses or the tightness of the flaps to the chamber walls is unsatisfactory, and the axial clearance of the flaps in the open state exceeds 0.3 mm, then the mixing chamber should be disassembled.

- - to completely disassemble the mixing chamber, you should:

- - unscrew the nut of the primary chamber throttle shaft lever and two screws securing the drive mechanism cover;

- - remove the drive lever and the low-speed lever with mounting washers, and the mechanism cover;

- - remove the linkage with the spring from the primary chamber throttle shaft.

Unscrew two screws and remove the primary and secondary chamber throttles;

- - remove the accelerator pump drive lever from the primary chamber throttle shaft and the nut with washer from the secondary shaft cameras;

- - remove both axles on the housings, simultaneously removing the return spring of the primary chamber axis.

Assembling the carburetor

The float must swing freely on its axis without jamming, while ensuring a needle stroke of at least 1.5 mm.

The fuel level in the carburetor float chamber must be 18.5-21.5 mm below the upper plane of the body and correspond to the marks on the carburetor body, which are visible through the inspection windows.

To obtain the correct level in the float chamber, it is permissible to bend the float bracket.

The diaphragm mechanism must be sealed. The test is carried out on a special stand.

At a vacuum of 1500-1700 mm H2O, st. no more than three bubbles per second of air may be released.

The diaphragm mechanism cover and the diaphragm drive lever mechanism cover must be sealed.

The throttle shaft must rotate freely in the bearings without jamming. The circumferential gaps between the valves and the housings should not exceed:

- - for throttle valves - 0.06 mm;

- - for air valves - 0.2 mm.

With the air valve fully closed, the valve throttles should open at least 12° from their fully open position.

The economizer valve should be fully engaged with the throttles fully open.

Testing

The assembled carburetor should be checked for leaks and the fuel level in the float chamber using the NIIAT-355 model device.

At an excess pressure of 0.3-0.32 kg/cm² for gasoline with a specific gravity of 0.720-0.750 g/cm³, the fuel level in float chamber should be 20 ± 1 mm to the plane of the carburetor connector.

The capacity of the accelerator pump should be at least 10 cm³ per 10 piston strokes.

The full engagement of the economizer valve is checked by measuring: the gap between the bar and the economizer drive nut, the distance between the upper plane of the carburetor cover and the upper plane of the bar.

The gap between the bar and the economizer drive rod nut with the upper plane of the bar at a distance of 13 ± 0.2 mm from the upper plane of the float chamber connector should be 3 ± 0.2 mm.

The distance between the upper split plane of the carburetor cover and the upper plane of the bar should be 21.5 ± 0.2 mm.

The operation of the diaphragm mechanism of the neumocentrifugal speed limiter is checked at special stand.

The carburetor speed limiter, when working with a reference sensor, must ensure automatic limitation of the engine crankshaft speed when it is operating with an air filter within the range of:

- - by speed characteristic - 3200-3400 rpm;

- - at idle - 3450-3550 rpm.

All carburetors coming out of repair must be tested on the engine in order to determine their main operating qualities, ensuring:

- - ease of engine starting;

- - stable engine operation at low idle speed;

- - no dips in operation.

The minimum stable engine crankshaft speed when idling must be within the range of 400— 500 rpm.

When checking the engine operation in various modes (with and without load), the carburetor must ensure a smooth, drop-free transition from one engine operating mode to another.

Carburetor adjustment

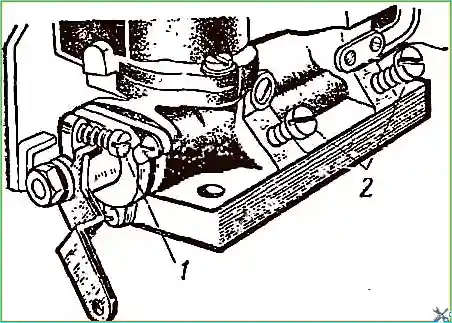

Fig. 4. Carburetor adjusting screws

Idle speed is adjusted using stop screw 1 (Fig. 4), which limits the closure of the throttles, and two screws 2, 2, which change the composition of the working mixture, on a well-warmed engine and with a serviceable ignition system.

Particular attention should be paid to the serviceability of the spark plugs and the correct gap in their electrodes.

When adjusting, it should be taken into account that the carburetor is two-chamber and the composition of the working mixture in each chamber is adjusted independently.

When starting the adjustment, screw 2 all the way in, and then unscrew each one by two turns.

Start the engine and use screw 1 to set the smallest throttle opening at which the engine runs quite stably.

Then lean the mixture with one of the screws 2, tightening it by ¼ at each test revolutions until the engine starts to run intermittently.

After this, enrich the mixture by turning screw 2 by ½ turn. Do the same with the second screw 2.

After adjusting the mixture composition, try to reduce the idle speed by turning the stop screw 1 of the throttles, then lean the mixture again with both screws in turn, as indicated above.

To check the idle adjustment, sharply press the throttle control pedal and release it sharply.

If the engine stops then the number of revolutions must be increased by the throttle stop screw.

A properly adjusted engine should operate stably at 475-525 rpm.