Carburetor 21073-1107010

To prepare the air-fuel mixture of the required composition (depending on the engine operating mode), use a carburetor 21073-1107010 - emulsion type, two-chamber, with a falling flow, with sequential forced opening of the throttle valves

Throttle valve drive – mechanical, lever.

The carburetor has a balanced float chamber, a crankcase gas suction system, heating of the throttle valve area of the first chamber, a mechanically driven starting device, and an electromagnetic idle shut-off valve.

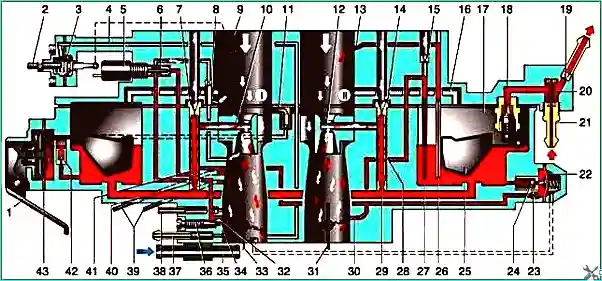

Diagram of the device and robots of the carburetor: I - first chamber; II - second chamber; 1 - accelerator pump drive lever; 2 - adjusting screw of the starting device; 3 - trigger diaphragm; 4 - air channel of the starting device; 5 - electromagnetic shut-off valve; 6 - idle fuel jet; 7 - main air jet of the first chamber; 8 - idle air jet; 9 - air damper; 10 - sprayer of the main dosing system of the first chamber; 11 - accelerator pump nozzle; 12 - sprayer of the main dosing system of the second chamber; 13 - econostat sprayer; 14 - main air jet of the second chamber; 15 - air jet of the transition system of the second chamber; 16 - channel for balancing the float chamber; 17 - float chamber; 18 - needle valve; 19 - calibrated hole for fuel bypass into the tank; 20 - carburetor fuel filter; 21 - fuel supply fitting; 22 - power mode economizer diaphragm; 23 - fuel jet of the power mode economizer; 24 - ball valve of the power mode economizer; 25 - float; 26 - econostat fuel jet with tube; 27 - fuel nozzle of the transition system of the second chamber with a tube; 28 - emulsion tube of the second chamber; 29 - main fuel jet of the second chamber; 30 - outlet of the transition system of the second chamber; 31, 33 - throttle valves: 32 - slot of the transition system of the first chamber; 34 - outlet of the idle system; 35 - carburetor heating block; 36 - adjusting screw for the composition (quality) of the idle mixture; 37 - crankcase ventilation fitting; 38 - fitting for supplying vacuum to the vacuum ignition regulator; 39 - vacuum intake fittings for the recirculation system; 40 - main fuel jet of the first chamber; 41 - emulsion tube of the first chamber; 42 - accelerator pump ball valve: 43 - accelerator pump diaphragm.

To start a cold engine, an air damper with a mechanical cable drive and a vacuum starting device is installed above the first chamber.

Fuel is supplied to the carburetor float chamber through a strainer installed behind the inlet fitting.

The float chamber is two-sectional (this design reduces the effect of fuel level fluctuations on engine operation when the vehicle turns and rolls).

The specified fuel level is maintained by a needle valve.

From the float chamber, fuel flows through the main fuel jets (first and second chambers) into the emulsion wells, where it is mixed with air passing through calibrated holes in the upper part of the emulsion tubes (main air jets).

The fuel-air emulsion then enters the small and large diffusers of the carburetor through the nozzles.

The idle system takes fuel from the emulsion well after the main fuel jet of the first chamber.

The fuel passes through the idle air jet (structurally combined with an electromagnetic idle shut-off valve), after which it is mixed with air from the channel from the idle air jet and from the expanding part of the diffuser (for stable operation when switching to idle mode).

The resulting emulsion is fed under the throttle valve through a hole closed by a quality screw.

The quantity (speed) screw regulates the opening of the throttle valve of the first chamber at idle.

When the throttle valve of the first chamber is partially opened (before the main metering system is turned on), the air-fuel mixture enters the chamber through a vertical slot located at the level of the throttle valve in the closed position; when the throttle valve of the second chamber is partially opened - through the hole located just above the throttle valve of the second chamber in the closed position.

The power mode economizer comes into operation when the throttle valves are opened significantly. Fuel is drawn from the float chamber through a ball valve.

As long as the economizer diaphragm is held by vacuum in the intake manifold, the valve is closed.

When the throttle the valves open, the vacuum behind them drops, and the pusher riveted to the diaphragm releases the valve.

In this case, fuel flows through the economizer jet into the emulsion well, bypassing the main fuel jet, enriching the mixture.

The econostat provides additional fuel supply directly from the float chamber (through the econostat jet and tube system) to the second chamber.

The econostat switches on at maximum power modes, further enriching the working mixture.

The accelerator pump is diaphragm type, mechanically driven from the throttle axis of the first chamber through a profile cam.

When the throttle valve opens, the cam acts on the lever, which in turn acts on the diaphragm.

A portion of fuel is injected through a sprayer into the first chamber of the carburetor, enriching the combustible mixture during acceleration modes.

The pump is equipped with two ball valves: a check valve is located in the channel connecting the float chamber with the cavity of the accelerator pump; it opens when it is filled with fuel (the gas pedal is released and the return spring moves the diaphragm back) and closes when fuel is pumped.

The other valve is located in the sprayer; it opens under the pressure of the pumped fuel and closes under its own weight as soon as the fuel supply stops.

This prevents fuel from leaking out of the channels and air leaks. Pump performance is determined by the cam profile.

The starting device serves to enrich the air-fuel mixture when starting a cold engine. It is controlled from the driver's seat by a "choke" handle via a cable.

When the handle is pulled all the way, the three-arm air damper control lever, turning on an axis, acts with a profile cutout on the air damper lever, closing it.

At the same time, with its outer profile (in the lower part) it acts on the throttle valve control lever of the first chamber, opening it slightly to the starting gap “C” (its value is adjusted by a screw on the lever).

After the engine starts running, the vacuum in the intake manifold increases and is transferred to the cavity of the starting device.

Under the influence of vacuum, the diaphragm of the starting device, overcoming the resistance of the return spring, through the rod slightly opens the air damper to the starting gap "B" (its value is adjusted by a screw on the cover of the starting device).

When the air damper control handle is recessed, gaps C and B are reduced; their value with a partially recessed handle depends on the profiles of the three-arm lever (its cutout and outer profile) and is not subject to adjustment.

If the choke control handle is pulled out, then when you press the gas pedal, only the throttle valve of the first chamber will open, since the throttle valve of the second chamber is blocked by a special lever mounted on the throttle valve drive lever.

This prevents jerks and dips when driving with a cold engine (with the choke control handle pulled out).

The forced idle speed economizer consists of a limit switch, an electromagnetic shut-off valve and a control unit.

The solenoid valve shuts off the fuel supply to the idle system and the transition system of the first chamber. The normal state of the valve (no voltage is supplied) is closed.

It opens when the gas pedal is pressed, as well as at a crankshaft speed of 1900 min –1 and below.

The valve closes if the gas pedal is released (the limit switch is shorted to ground) and the engine speed exceeds 2100 min -1, as well as when the ignition is turned off, which prevents the engine from operating when the ignition is turned off (dieseling ).

The mixture prepared in the carburetor enters the engine cylinders through the intake manifold.

It is cast from aluminum alloy and is attached to the engine with studs through heat-resistant gaskets.

Carburetor calibration data 21073-1107010

Diameter of the mixing chamber - 32 mm;

Diffuser diameter - 24 mm;

Spray marking:

- - first camera 7;

- - second camera 6;

Main dosing system:

Fuel jet marking

- - first camera 107.5;

- - second camera 117.5

Air jet marking

- - first camera 150;

- - second camera 135

Emulsion tube type

- - first ZD camera;

- - second ZC camera

Idle system of the first chamber and transition system of the second chamber:

Fuel jet marking

- - first camera 39;

- - second camera 70

Air jet marking - 140

Econostat:

- conventional fuel jet flow rate - 70

Economizer of power modes:

- fuel jet marking - 40

Effort spring compression with a length of 9.5 mm, N - 1.5±10%

Accelerator pump:

- - sprayer marking - 45;

- - fuel supply for 10 cycles, cm 3 - 14;

- - cam marking - 4;

- - Starting gaps: air damper (gap B), - 3.0 mm;

- - throttle valve (gap C), - 1.1 mm;

- - Hole diameter for vacuum corrector, 1.2 mm;

- - The diameter of the needle valve hole is 1.8 mm;

- - Diameter of the fuel bypass hole into the tank, 0.70 mm

- - Diameter of the engine crankcase ventilation hole, 1.5 mm