The fuel rail is removed to check and replace the injectors, as well as when replacing the rail itself or the intake pipe

You will need: a 5 mm Allen key, a screwdriver, and a 17 mm wrench (two).

Remove the receiver from the intake pipe (see "How to Replace the Niva Chevrolet Receiver Gasket").

Drain some of the coolant by unscrewing the plug on the cylinder block (see "Replacing the Niva Chevrolet Coolant").

Loosen the clamp securing the heater radiator hose and remove it from the cylinder head pipe.

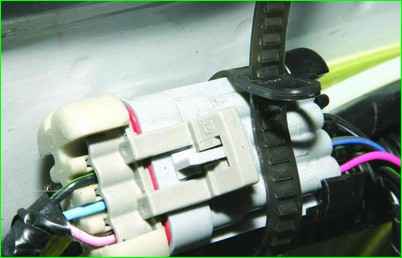

Unfasten or cut the plastic clamp securing the injector wire block to the front shield.

Disconnect the injector wiring harness from the wiring harness of the control system.

Using a 17 mm wrench, unscrew the fuel supply pipe fitting, holding the end of the hose with a wrench of the same size size.

Similarly, we disconnect the tube fitting from the drain pipe hose.

Having disconnected the tubes and hoses, we check the condition of the rubber sealing rings put on the ends of the tubes.

Using a 5 mm Allen key, unscrew the two screws securing the fuel rail to the intake pipe.

Pulling the rail along the axes of the injectors, remove all four injectors from the holes in the intake pipe, remove the rail assembly with the fuel pressure regulator, fuel pipes, injectors and harness wires.

All injectors must remain on the fuel rail.

If any injector remains in the intake pipe, it is necessary to replace the spring retainer and the injector body sealing ring.

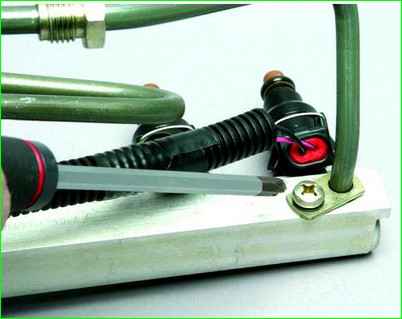

To remove the fuel supply pipe to the rail, use a Phillips screwdriver to unscrew the screw securing the pipe holder.

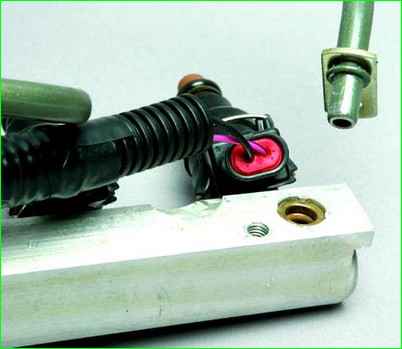

Removing the tube from the ramp

The end of the tube is sealed with a rubber ring

Install the ramp in the reverse order.

Damaged rubber sealing rings replace them with new ones and apply engine oil to them during installation.

The tightening torque of the ramp mounting screws is 9–13 Nm, and the fuel pipe fittings are 20–34 Nm.