If the gasket between the flanges of the receiver and the intake pipe is damaged, normal engine operation cannot be achieved, since the additional air sucked into the intake pipe does not allow the engine management system to provide the optimal composition of the combustible mixture required for each engine operating mode.

If you cannot eliminate the air leak by tightening the nuts securing the receiver to the intake pipe, replace its gasket.

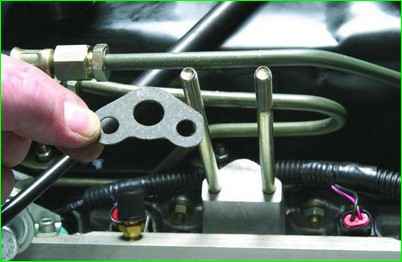

This is what the gasket between the receiver and intake manifold

You will need: a 13 mm wrench (a socket wrench is more convenient), a screwdriver.

If the throttle assembly is electrically driven, then you need to disconnect the wiring block

If the throttle assembly is mechanically driven, then:

Remove the safety bracket from the throttle sector by prying it up with a screwdriver.

Remove the throttle cable end from the sector groove and disconnect cable from the throttle assembly.

Remove the cable sheath holder from the hole

Loosen the clamp and remove the purge hose from the throttle body pipe.

Loosen the fastening clamp and disconnect the right part of the air supply pipe from the intermediate bracket

Unscrew the upper and lower nuts securing the throttle assembly to the receiver and move the throttle assembly away from the receiver without disconnecting the remaining hoses from it

Disconnect the hose from the fuel pressure regulator

Loosen the clamp and remove the brake booster hose from the receiver pipe.

Unscrew the five nuts securing the receiver to the intake pipe

Please note: flat washers are installed under the nuts. Don't lose them.

Remove the right rear bracket for mounting the decorative cover and remove the receiver from the studs of the intake pipe.

Please note: a spacer is installed on the studs of the inlet pipe.

If you removed it, do not forget to install it in place when installing the receiver.

Remove the receiver gasket and clean the mating surfaces of the flanges of the inlet pipe and receiver from gasket residues

Install a new gasket and all removed parts and assemblies in in the reverse order of removal.

Tighten the receiver mounting nuts evenly crosswise to a torque of 20.87 – 25.77 Nm (2.13 – 2.63 kgfm).