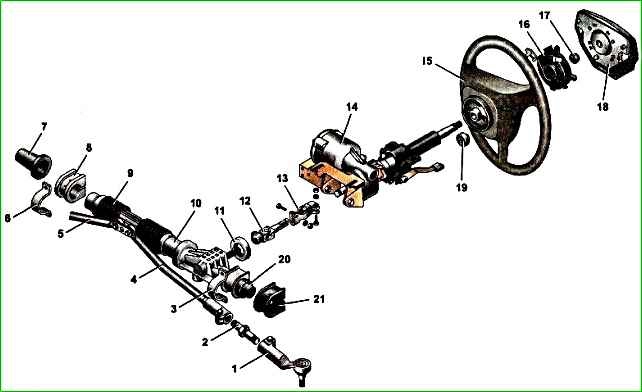

Steering — trauma-safe, with electric power steering and height-adjustable (tilt angle) steering column

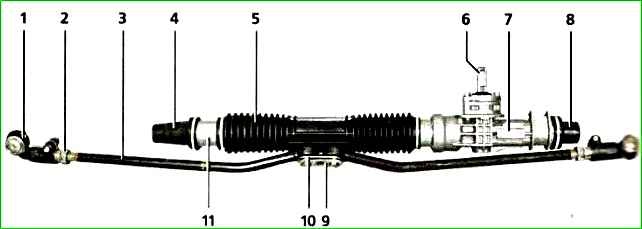

Steering mechanism — rack-and-pinion type with variable gear ratio.

It is secured in the engine compartment on the front shield of the body with two brackets through rubber supports.

Fastening bolts — welded, two on each side of the front shield.

The steering gear housing is cast, made of aluminum alloy.

On the right side, a pipe with a longitudinal groove is inserted into the housing, secured in the housing with a nut.

A helical drive gear (gear shaft) is installed in the housing, which is in engagement with the rack.

The rack has helical teeth with a variable pitch (closer to the ends of the cut part of the rack, the pitch of the teeth decreases).

To reduce the load on the gear shaft and its bearings under extreme operating conditions, a plastic gear sleeve with a metal support plate is inserted into the housing.

The gear shaft rotates on two bearings: the front (on the end of the shaft) is a needle bearing, the rear (closer to the steering column shaft) – ball.

Since axial loads can be high in helical gearing, a thrust roller bearing consisting of a plastic separator with rollers of the lower (inner) and upper (outer) rings is additionally installed on the drive gear shaft.

The lower bearing ring is pressed onto the drive gear shaft until it stops against the inner ring of the ball bearing, and the upper one is installed in the crankcase cover.

In addition, the crankcase cover presses the outer ring of the ball bearing against the end face of the bearing seat.

A drive gear oil seal is installed in the cover, and a sealing ring is installed between the cover and the steering gear housing.

The cover is closed with a protective cover (dust cover) mounted on the drive gear shaft.

The rack is pressed against the teeth of the gear by a spring through a stop sealed in the crankcase by a rubber ring.

A plastic insert is installed to reduce friction between the stop and the rack.

The spring, in turn, is pressed by an adjusting nut (internal octagon "24").

At the manufacturer, when assembling the steering gear

a gap of 0.1 mm is set in the engagement of the rack with the gear, after which the thread of the crankcase is punched (pressed) at two points (without damaging the nut).

The other end of the rack rests on a plastic sleeve, which is inserted into the pipe behind the longitudinal groove.

Adjusting the gap between the gear and rack is made after disassembling the steering mechanism or when knocking occurs during operation.

The clearance can only be adjusted with the steering mechanism removed. We set the rack to the middle position and block it from moving.

After removing the rubber plug, we insert the leg of the clock indicator into the hole of the stop adjusting nut until it touches the rack stop.

By turning the pinion shaft (torque 15 Nm), while the pinion pushes the rack and the stop, we determine the amount of stop movement by the indicator.

If it exceeds 0.05 mm, by tightening the adjusting nut, we achieve the specified amount of stop movement.

After this, having unlocked the rack, we check the ease of rotation of the pinion shaft in the entire range of the rack travel.

The crankcase pipe is covered with a protective corrugated cover.

The rods are attached to the rack with bolts passing through the connecting plates and spacer bushings of the rubber-metal hinges, as well as the rod support installed on the rack.

The bolts are prevented from spontaneously loosening by a locking plate put on the bolt heads.

For lubrication of the gear, rack and bearings, use FIOL-1 grease (approximately 20-30 g for the entire mechanism).

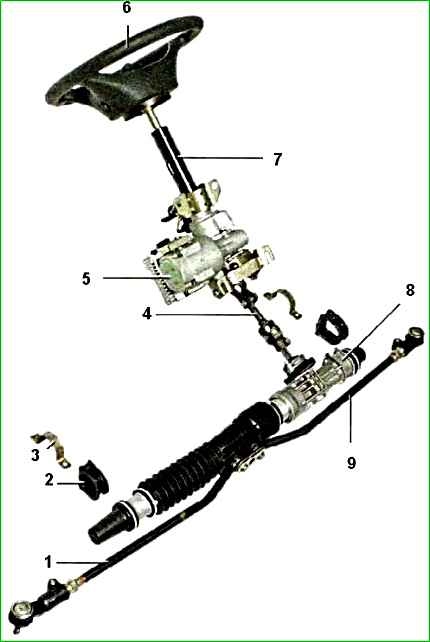

The steering shaft is connected to the gear shaft through an intermediate cardan shaft.

The steering shaft rotates in two ball bearings, one of which is installed in the steering column bracket tube, and the second in the housing electric power steering.

The steering column bracket is secured with nuts at four points:

- the front part — to the pedal bracket, the rear part — to the bracket on the body.

The steering column bracket and its pipe are connected to each other by pivots with two plates through plastic and metal bushings, tightened with four bolts.

Thus, the pipe can move in the vertical plane, relative to the bracket, allowing you to adjust the position of the steering wheel in height.

The movement is limited by the length of the slots in the plates. The steering column adjustment lever is used to fix the pipe relative to the bracket.

It is connected to the adjusting sleeve with a splined hub and fixed on it with a locking ring.

The sleeve is screwed onto a tie bolt passing through the slots of the plastic pipe and bracket guides.

A spacer sleeve is installed on the bolt. The bolt head is secured against turning by a special protrusion.

When the lever is turned down, the bushing unscrews and the tightening force of the plates weakens, which allows you to manually change the position of the steering column.

Springs are installed between the plates and the bracket, pulling the bracket pipe to the upper position when the connection is loosened.

After installing the steering column in the required position, the lever is raised up and the connection is tightened, fixing the column.

The steering drive includes two composite steering rods and pivot arms welded to the shock absorber struts of the front suspension. Each rod, in turn, consists of three parts - an inner tip, an outer tip and an adjusting threaded sleeve.

The adjusting sleeve is a tube with a hexagon at the end, with external and internal threads of different directions.

The length of the steering rod changes when the adjusting sleeve is rotated.

After the adjustment is complete, the outer ends of the steering rods are tightened with bolts.

The steering rod is connected to the steering arm through the outer tip with a ball joint.

To protect against dirt, the joint is covered with a rubber protective cover (dust cover).

The joint forms a non-separable structure with the tip, so if it fails, the tip should be replaced with subsequent adjustment of the wheel alignment.

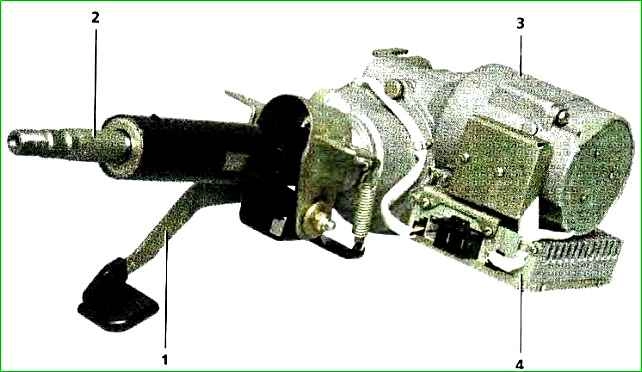

The electric power steering reduces the effort on the steering wheel, making it easier to control the car.

The basis of the electric power steering is a brushless electric motor with a gearbox located under the steering cover.

A worm is installed on the motor shaft, which engages with a plastic gear fixed to the steering shaft.

The operation of the electric power steering is coordinated by an electronic control unit by changing the voltage supplied to the electric motor based on information received from vehicle speed sensors, crankshaft speed and the magnitude of the torque on the steering shaft.

The electric motor turns the steering column shaft with a certain torque through the gearbox.

The control unit provides sufficient information from the steering wheel in all driving modes of the car.

When the car is stationary, the power created by the electric power steering the moment on the shaft is maximum, with the increase in the speed of the car, the "assistance" of the amplifier decreases and the steering wheel becomes "heavier".

In the event of failure of the electric power steering, the car retains full control, while the steering wheel becomes somewhat "heavier" than in a car without an electric power steering, since there is an additional load in the form of freely rotating rotor of the electric motor.

The instrument cluster contains a power steering malfunction indicator.

It lights up when the ignition is turned on and goes out after the engine starts.

If the power steering is faulty, the indicator lights up constantly. The electric power steering does not work when the engine is not running.

The electric power steering can be switched off:

- - when the voltage of the on-board network drops;

- - when there is no signal from the speed sensor and the engine speed is above 1500 min -1.

Such shutdowns are built into the electric power steering algorithm and are not signs of a malfunction.

Steering play (free play of the steering wheel in the position corresponding to straight-ahead driving, measured along the steering wheel rim), no more than 5˚ or 18 mm.

Tightening torques of threaded connections of the steering

Name of units - Thread - Tightening torque, Nm (kgcm)

- Steering gear fastening nut M8 - 15—18.6 (1.5—1.9)

- Steering column fastening nut М8 - 15—18.6 (1.5—1.9)

- Nuts of the tie bolts for fastening the intermediate shaft flanges М8 - 23—27.4 (2.3—2.8)

- Tie rod tie bolt М10х1 - 19—30.9 (2.0—3.2)

- Steering wheel fastening nut М16х1.5 - 31.4—51 (3.2—5.2)

- Tie rod ball joint fastening nut М12х1.25 - 27.1—33.4 (2.8—3.4)

- Steering rod fastening bolt to the steering gear М 10х1 - 70—86 (7.1—8.6)

- Steering gear pinion bearing nut М38х1.5 - 45—55 (4.6—5.6)

Checking the technical condition of the steering

1. Visually check the condition of the protective covers of the tie rod ends and steering gear.

Damaged covers (torn, with cracks) must be replaced.

2. Make sure that the steering column locking lever is raised to the stop.

Trying to move the steering wheel in the vertical plane, check the reliability of the steering column fastening by the locking mechanism.

If the steering column moves, remove the steering column pads, use a 10 mm wrench to loosen the tightening of the lever fastening bolt (left-hand thread) and use a 17 mm wrench to tighten the steering column locking lever axle nut.

After that, tighten the bolt.

Trying move the steering wheel along the axis of the steering shaft, make sure that there is no play in the steering wheel on the splines of the shaft and the shaft in the steering column.

To check for play in the steering, turn the steering wheel to the position corresponding to driving straight ahead.

Place a slotted screwdriver on the dashboard so that its blade is located next to the rim of the steering wheel (for reliability, you can secure it with masking tape).

Turning the steering wheel to the right until the wheels start to turn (selecting backlash), and then to the left and using a screwdriver blade, chalk, wire segments or some other method to mark these positions on the rim.

The backlash should not be more than 5° (or 18 mm) when measured along the outer part of the rim.

Increased backlash indicates the need to find and fix the fault.

As a rule, the first thing to fail in the steering is the tie rod ends.

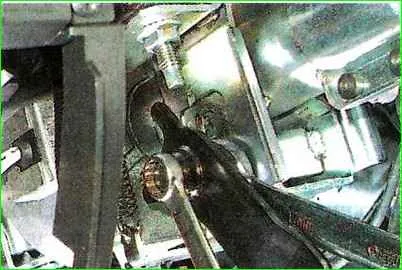

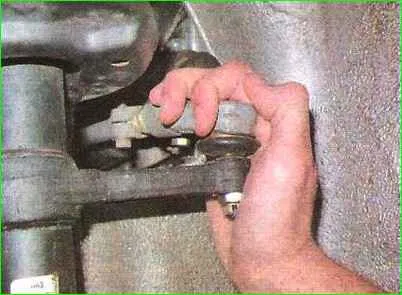

To check for backlash in the tie rod ends, the assistant slightly rocks the steering wheel from side to side.

Place your hand on the junction of the steering rod with the steering arm of the suspension strut so that your palm touches them simultaneously.

If there is play in the steering rod end, you will feel the steering arm shifting relative to the rod.

Check the tightening of the nuts of the steering column universal joint bolts

Repeat the check on the other side of the car. Replace faulty joints.

When rocking the steering wheel from side to side, listen to the operation of the steering mechanism.

A knock from the right edge of the steering mechanism indicates wear of the support bushing.

Remove and repair or replace the faulty steering mechanism.

Turn on the ignition - the control lamp for a malfunction of the electric power steering should light up on the instrument panel.

Start the engine. the indicator lamp should go out, the steering wheel should be easy to turn with one hand.

If the lamp lights up while the engine is running, it indicates that the electric power steering is faulty and needs to be repaired.