Remove the gearbox (see "Removing and installing the Lada Priora gearbox")

Clean it from dirt on the outside (do not allow dirt to get inside the gearbox)

Remove the speed sensor.

For ease of further disassembly of the gearbox, screw two nuts onto the clutch housing mounting stud, unscrew the stud from the clutch housing.

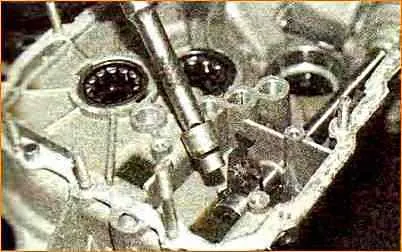

Install the gearbox on the workbench with the clutch housing down.

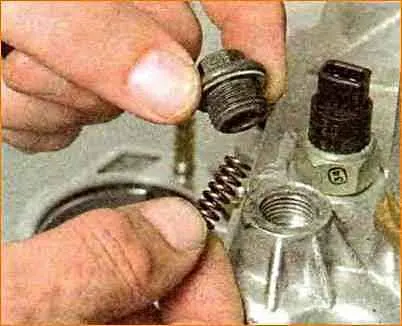

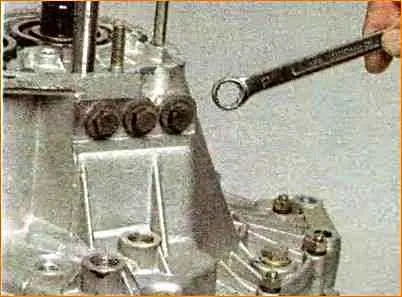

Using a 13 mm open-end wrench, unscrew the plug of the reverse gear engagement fork retainer.

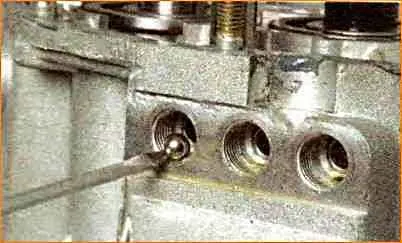

Remove the retainer spring from the crankcase hole

Using a magnet, remove the retainer ball.

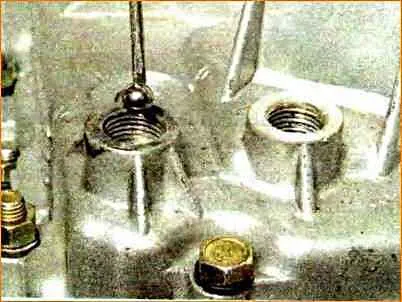

Unscrew the reverse gear lock solenoid and the reverse light switch from the gearbox crankcase holes.

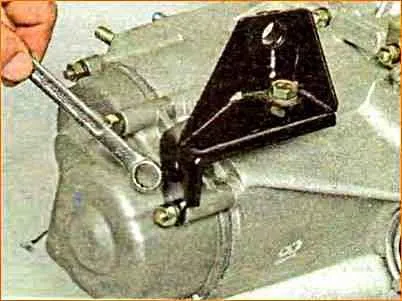

Using a 13 open-end wrench, unscrew the nut securing the rear cover of the gearbox housing, which simultaneously secures the clutch release cable bracket.

Using a 17 open-end wrench, unscrew the mounting bolt clutch release cable bracket.

Removing the bracket.

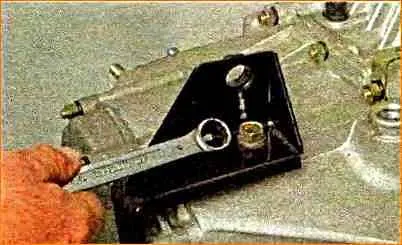

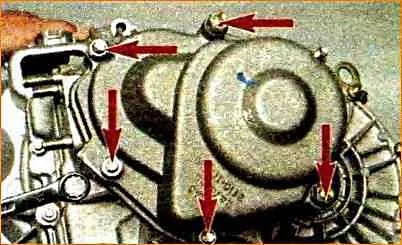

Using a 13 mm open-end wrench, unscrew five more nuts securing the rear crankcase cover.

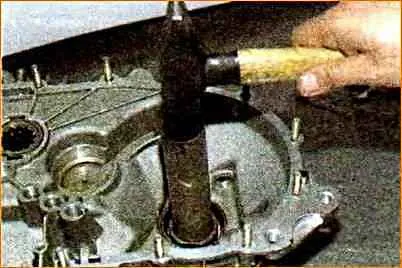

Tapping with a hammer with a plastic tip or a regular hammer through a soft metal mandrel on the cover lugs.

Remove the cover from the studs.

To unscrew the shaft nuts, it is necessary to lock the shafts from turning by engaging two gears at once.

To do this, by pressing the gear shift rod all the way in, engage the third gear.

With a 10 mm open-end wrench unscrew the bolt securing the 5th gear fork.

Using a soft metal punch, strike the fork, engaging 5th gear.

Using a punch, we straighten the places where the flanges of the primary and secondary shaft nuts were punched.

Using a 32 mm head with a powerful handle, we unscrew the shaft nuts.

Prying off the driven gear of the fifth gear with a screwdriver, remove the V gear unit as a whole.

Remove the V gear engagement fork.

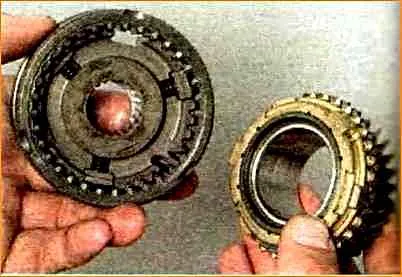

Having marked the position of the synchronizer locking ring relative to the clutch, remove the 5th gear with the synchronizer locking ring.

Remove the synchronizer locking ring.

Remove the synchronizer thrust plate.

Use a screwdriver to pry up the sleeve of the driven gear of the V gear

Remove the gear from the secondary shaft

Insert one or two screwdrivers into the gap between the thrust plate and the V-gear pinion.

Prying the gear with a screwdriver, press it off the input shaft.

Remove the thrust ring from the secondary shaft.

Using an impact screwdriver with a Phillips tip RNZ, unscrew the four screws securing the thrust plate bearings.

Special lock washers are installed under the screw heads.

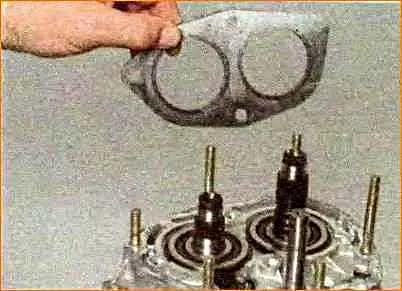

Removing the plate

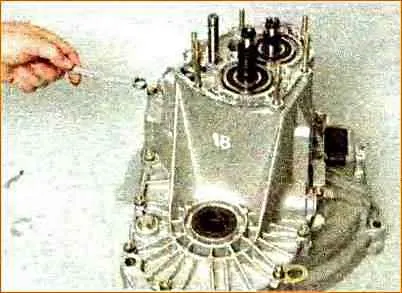

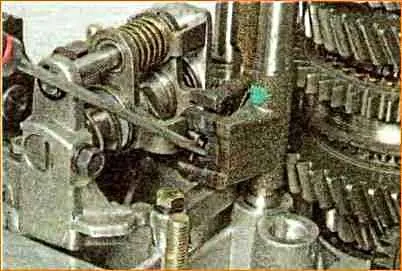

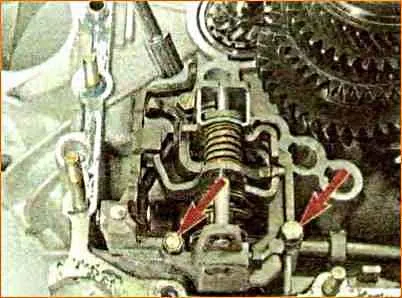

Using a 13 mm open-end wrench, unscrew the three plugs holding the gearshift fork rods.

We remove the locking balls with a magnetic screwdriver.

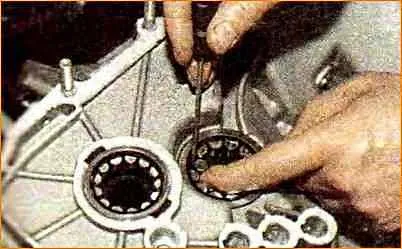

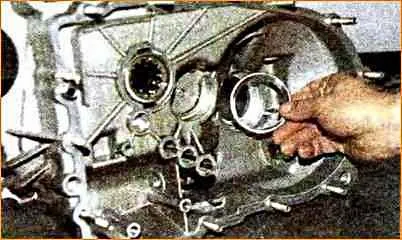

We use two screwdrivers to spread the ends of the retaining ring of the rear bearing of the input shaft and remove the ring from the crankcase groove.

Similarly, remove the retaining ring of the rear bearing on the secondary shaft.

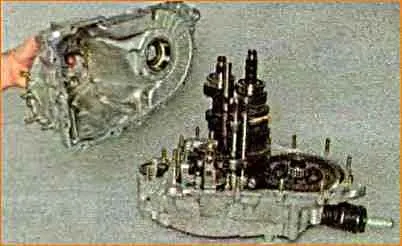

Using a 13 mm open-end wrench, unscrew one bolt and thirteen nuts securing the gearbox housing to the clutch housing.

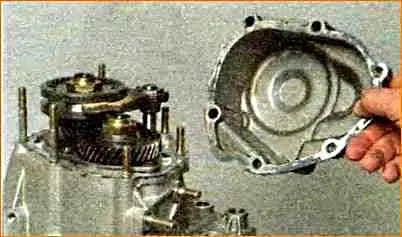

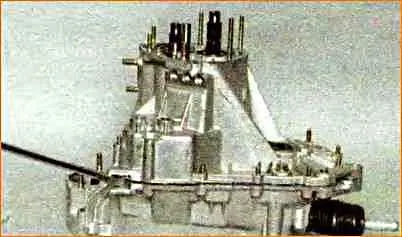

Insert a screwdriver into the groove at the junction of the mating surfaces of the housings.

Carefully lift the gearbox housing and remove it

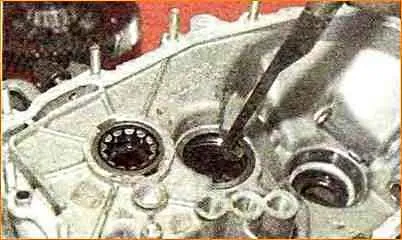

Remove the magnet from the housing recess.

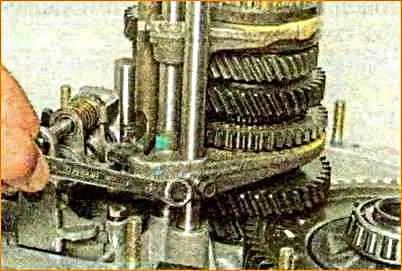

Using a 10 mm open-end wrench, loosen the bolt securing the fork of the first and second gears to the rod.

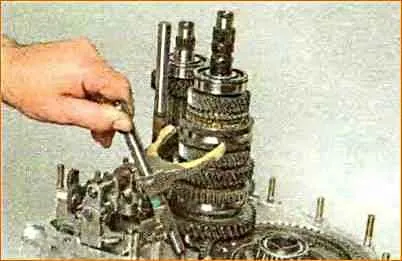

Lift the rod upwards and remove the fork from the groove of the sliding synchronizer clutches.

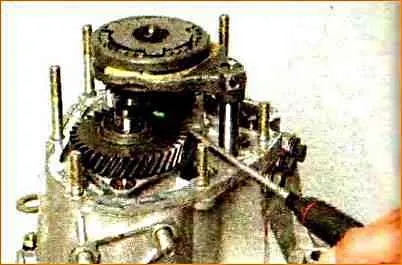

Using a 10 mm open-end wrench, unscrew the bolt securing the III-IV gear fork to the rod

Use a screwdriver to remove the rod lever from the gearshift mechanism.

Lift the rod up and remove the fork from the groove of the synchronizer sliding clutch.

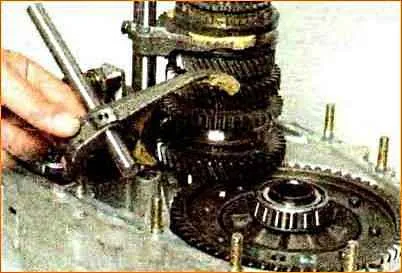

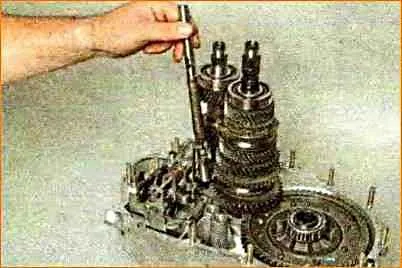

By turning the rod of the 1st gear engagement fork, we disengage the rod lever in the gear shift mechanism

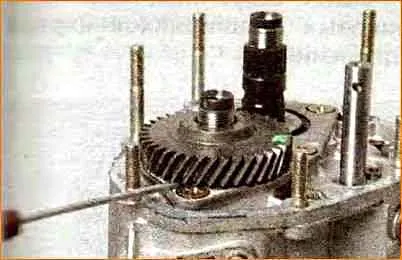

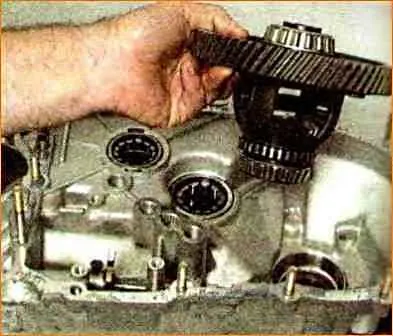

We take out the axis of the intermediate gear of the reverse gear

Remove the intermediate gear of the reverse gear

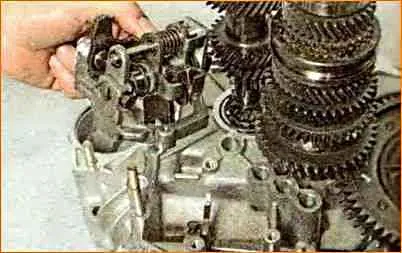

Using a 10 mm socket, unscrew the three bolts securing the gear shift mechanism.

Removing the gear shift mechanism

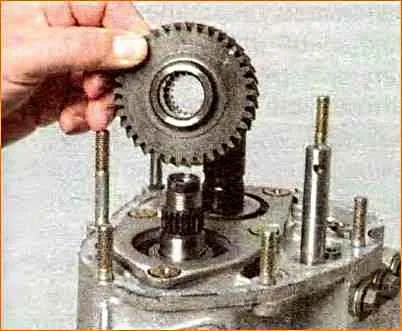

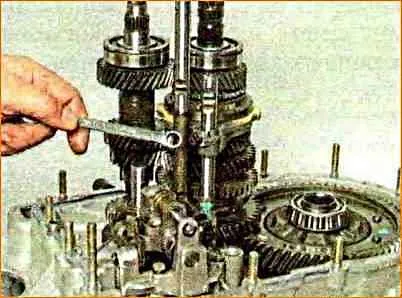

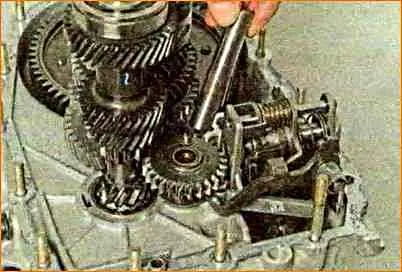

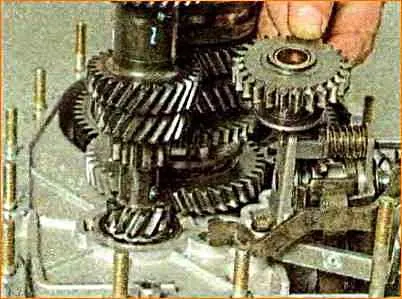

Simultaneously removing the primary and secondary shafts from the roller bearings of the clutch housing.

We take out the differential assembly.

The universal joint of the gearshift rod can be replaced on the car without removing the gearbox, by disconnecting the gearbox control rod from the joint tailstock.

For clarity, we show the removal of the joint on the removed gearbox.

We move the protective cover from the rod hinge and with a 10 head unscrew the conical screw of the hinge.

We remove the hinge and the protective cover of the hinge from the rod.

If you need to remove the gear shifter or its rod, use a 10 head to unscrew the conical screw securing the gear shifter.

Pushing the rod out of the crankcase hole, remove the gear shifter from the rod gearbox.

For replacing the rod seal, see the article “How to replace the Lada Priora wheel drive seals.”

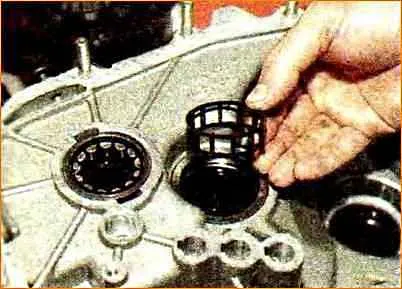

Using a screwdriver, remove the rollers of the front bearing of the secondary shaft from the separator.

We take out the bearing separator.

We hook the impact puller onto the flange of the outer ring of the bearing

And press out the outer bearing ring.

Remove the oil pan.

In the same way, press out the outer bearing ring of the input shaft.

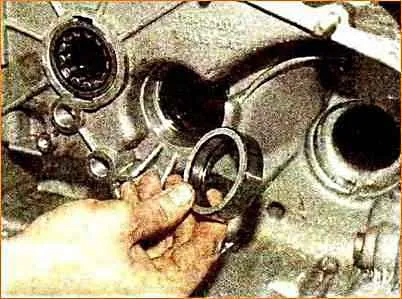

Using a suitable piece of pipe, knock out the wheel drive oil seal from the clutch housing

Wheel drive oil seal.

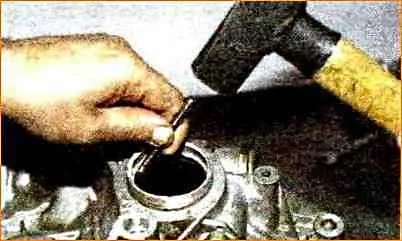

Using a punch, we strike the end of the outer ring of the differential bearing.

And press out the ring.

In the same way we knock out oil seal and outer ring of differential bearing from gearbox housing

Remove adjusting ring

Disassembly and assembly of primary shaft, secondary shaft, differential and synchronizer will be considered in the article — «Disassembly and assembly of shafts, differential and synchronizer of Lada Priora gearbox».

Gearbox assembly

To check technical condition of gearbox parts, we thoroughly clean and wash them.

Surfaces of housings under bearings and rods should not be damaged.

On threaded part of shafts, on splines and surfaces of shafts under gears and bearings damage is not allowed.

On mounting surfaces of gears there should be no scoring and signs of wear. Chipping and excessive wear of gear teeth are not allowed.

Ball and roller bearings should not have damage on the raceways, separators, balls and rollers, as well as cracks and chips on the rings.

Rotation of bearing rings should be smooth, without jamming.

Replace damaged bearings with new ones. Deformation of the gear shift rods and forks is not allowed.

The working surfaces of the forks that contact the grooves of the synchronizer sliding clutches must not have excessive wear.

The rods in the housing holes must move freely, without jamming.

Assemble the gearbox in the reverse order.

When assembling the differential, lubricate the satellites and drive gears with transmission oil.

Mount the differential bearings with a preliminary tension.

Tension is ensured by selecting the thickness of the adjusting ring installed in the gearbox housing socket under the outer ring of the differential bearing.

Selection of the thickness of the adjusting ring is necessary in case of replacement of one of the following parts: differential case, differential bearing, clutch housings and gearbox gears.

The differential bearing preload should be 0.25 mm.

To ensure this preload, it is necessary to select the correct thickness of the adjusting ring.

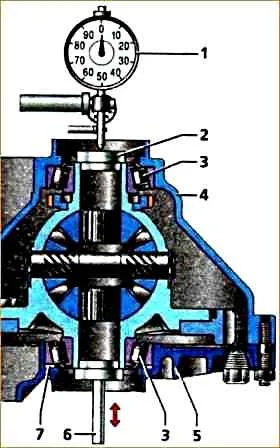

When selecting the adjusting ring, you will need: a 1.25 mm thick installation ring, a stand with a dial indicator, and a mandrel.

Insert the installation ring into the gearbox housing socket and press in the outer ring of the differential bearing using a mandrel of the appropriate diameter.

Similarly, press in the outer ring of the differential bearing into the clutch housing.

Install the differential into the gearbox housing, then install the clutch housing and tighten the housings with nuts (at least three located at equal distances).

Turn the differential a few turns to self-install bearings.

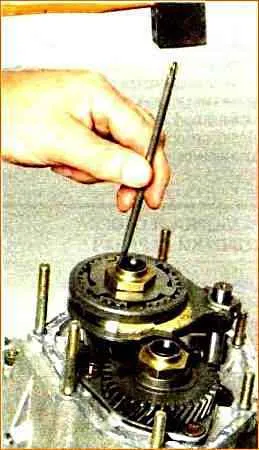

We install a mandrel (in the form of a plug) on the end of the differential, and a stand with an indicator on the clutch housing so that the leg rests on the mandrel, and create a tension on the indicator of 1 mm.

We move the differential up and take the indicator readings.

The thickness of the adjusting ring is calculated using the formula:

S=A+B+C

- where "S" is the thickness of the adjusting ring, "A" is the value of the axial movement of the differential, "B" is the value of the preliminary tension of the differential bearings, "C" is the thickness of the adjusting ring (1.25 mm).

After determining the thickness of the adjusting ring, we disconnect the gearbox and clutch housings, remove the differential, press out outer bearing ring from the gearbox housing and replace the mounting ring with the selected adjusting ring.

Adjusting rings with a thickness of 1.65 mm to 2.65 mm, with a step of 0.05 mm, are supplied as spare parts.

After installing the differential in the clutch housing, it is necessary to fix one of the wheel drive gears with a mandrel (plug) so that they do not move from their seats during further assembly.

When assembling the gear shifter and the hinge of the switch rod with the pre-load rod, o degrease the threaded holes in the hinge housing and switch, as well as the conical screws that secure them.

Before tightening, apply thread sealant to the screw threads. The outer rings of the roller bearings of the shafts, the seals of the primary shaft, drives and gear shift rod are pressed in using mandrels or suitable pipe sections.

Apply a thin layer of transmission oil to the working edges of the seals.

If the seals of the wheel drives have oil-scraping notches, then we install an oil seal with a right notch in the clutch housing (for the right drive), and an oil seal with a left notch in the gearbox housing (for the left drive).

The arrows on the seal housings must match the direction of rotation of the drives when the car is moving forward.

When assembling the secondary shaft, lubricate the parts with transmission oil.

Replace the retaining rings of the synchronizer hubs with new ones.

The synchronizer hubs, the inner ring of the roller bearing, the ball bearing and the leading press the main gear pinion onto the shaft using mandrels or suitable pipe sections.

After assembling the secondary shaft, check the operation of the synchronizers by manually moving the synchronizer clutches to the position of engaging the corresponding gears.

Press the inner ring of the roller bearing and the ball bearing onto the primary shaft.

Before installing the shafts, engage the teeth of the gears of both shafts and install the shafts in the clutch housing in this position.

Before assembling the gearbox housing with the clutch housing and the rear cover, apply a thin layer of sealant along the perimeter of the mating surfaces.