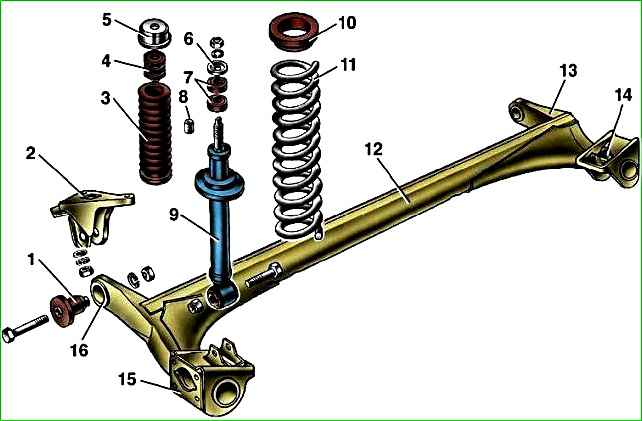

The car has a semi-independent rear suspension, made on an elastic beam with longitudinal arms, cylindrical springs and double-acting telescopic shock absorbers

The rear suspension beam consists of two longitudinal arms connected by a U-shaped cross-member.

This cross-section provides the connector (cross-member) with greater bending rigidity and less torsional rigidity.

The connector allows the arms to move relative to each other within small limits.

The arms are made of a pipe with a variable cross-section, which gives them the necessary rigidity.

Brackets for attaching the shock absorber, rear brake shield and wheel hub axle are welded to the rear end of each arm.

At the front, the beam arms are secured with bolts in removable brackets on the body side members.

The mobility of the arms is provided by rubber-metal hinges (silent blocks) pressed into the front ends levers.

The lower eye of the shock absorber is attached to the arm bracket of the beam.

The shock absorber is attached to the body with a rod with a nut.

The elasticity of the upper and lower connections of the shock absorber is provided by the rod cushions and the rubber-metal bushing pressed into the eye.

The shock absorber rod is covered with a corrugated casing, protecting it from dirt and moisture.

When the suspension breaks down, the stroke of the shock absorber rod is limited by a compression stroke buffer made of elastic plastic.

The lower coil of the suspension spring rests on the support cup (a stamped steel plate welded to the shock absorber body), and the upper one rests against the body through a rubber gasket.

An axle is installed on the flange of the arm of the beam. rear wheel hub (it is fastened with four bolts).

The hub with a double-row roller bearing pressed into it is held on the axle by a special nut.

The nut has an annular flange that securely locks the nut by pressing it into the axle groove.

The hub bearing is of a closed type and does not require adjustment or lubrication during vehicle operation.

Rear suspension springs are divided into two classes: "A" - more rigid, "B" - less rigid.

Class "A" springs are marked with brown paint, class "B" - with blue paint.

Springs of the same class must be installed on the right and left sides of the vehicle.

Springs of the same class are installed in the front and rear suspension.

In exceptional cases, it is permissible to install class "B" springs in the rear suspension, if in class "A" springs are installed in the front.

It is not allowed to install class "A" springs on the rear suspension if class "B" springs are installed in the front.

Checking the condition of the suspension

You can assess the technical condition of the suspension while the car is moving.

When driving at low speed on an uneven road, the suspension should work without knocking, creaking or other extraneous sounds.

After driving over an obstacle, the car should not swing.

It is better to combine the suspension check with checking the condition of the tires and wheel hub bearings.

One-sided wear of the tire tread indicates deformation of the rear suspension beam.

Sequence of execution:

1. Preparing the car for work.

It is better to check the performance of the shock absorbers after a long trip, while the working fluid in the shock absorbers has not cooled down.

2. Vigorously swing the rear of the car body in the vertical direction.

If the body continues to oscillate (more than two times: up and down) after it has stopped swinging, then one or both shock absorbers are faulty.

To identify a faulty shock absorber, repeat the test, applying force first on one side of the car, then on the other.

This test only identifies faulty shock absorbers.

The efficiency of vibration damping by shock absorbers can only be checked on a special stand.

3. Inspect the suspension shock absorbers - no fluid leaks from the shock absorbers are allowed.

Shock absorbers should be replaced in pairs, even if the second shock absorber of the rear suspension is in good condition.

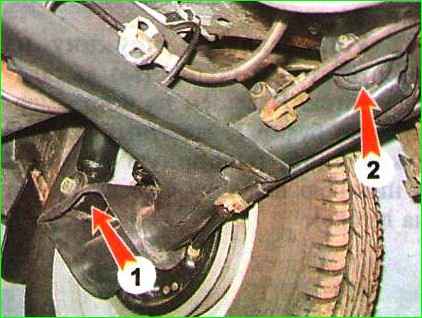

4. Visually check the condition of the rubber-metal hinges of the shock absorbers 1 and the levers of the rear axle beam 2.

Hinges with one-sided bulging of the rubber, ruptures and cracks are replaced.

5. Check the tightening of the suspension component mounting nuts and tighten them if necessary.

Rear suspension threaded connection tightening torques

Name of units and parts – Thread - Tightening torque Nm (kgcm)

- Wheel mounting bolts - М12х1.25 - 65.2-92.6 (6.7-9.5)

- Rear wheel hub bearing nut - М20х1.5 - 186.3-225.6 (19.0-23.0)

- Nut of the lower shock absorber mounting bolt to the rear suspension arm - М12х1.25 - 66.6-82.3 (6.8-8.4)

- Rear suspension shock absorber rod mounting nut to the body М10х1.25 - 50.0-61.7 (5.1-6.3)

- Nuts for bolts securing rear suspension arm to bracket М12х1.25 - 66.6-82.3 (6.8-8.4)

- Nuts for securing rear suspension arm bracket to body М10х1.25 - 27.4-34.0 (2.8-3.5)

Inspect suspension parts. Deformation and fatigue cracks in suspension parts are not allowed. Replace damaged parts.

Replace springs, like shock absorbers, in pairs.