Work is performed on a lift or inspection pit

Secure the engine cooling system radiator to the front crossmember of the engine compartment with straps (technological belts)

Remove the front wheels.

Remove the engine sump guard.

Remove the lower and side mudguards of the front fenders.

Unscrew the three screws securing the lower part of the bumper to the front suspension subframe and move the lower part of the bumper away, releasing the subframe (replaceable TorxT30 nozzle, extension, ratchet wrench).

For cars with a K7M engine, remove the catalytic converter.

Unscrew and remove the bolts securing the subframe braces to the side members (replaceable head 13, wrench ratchet).

Unscrew the nuts and remove the bolts securing the ball joints to the steering knuckles (ring spanner 16, replaceable head 16, ratchet wrench).

Disconnect the ball joints of the front suspension arms from the steering knuckles (mounting blade).

Unscrew the bolt securing the low-pressure pipe to the front suspension subframe (replaceable head 10, ratchet wrench).

For vehicles with a K4M engine, remove the oxygen sensor wiring harness from the retainer on the steering gear heat shield, unscrew the bolts securing the steering gear heat shield and remove the shield (replaceable head 13, ratchet wrench).

Unscrew the bolts securing the steering gear to the subframe and attach the steering gear to the vehicle body (replaceable head 18, ratchet wrench).

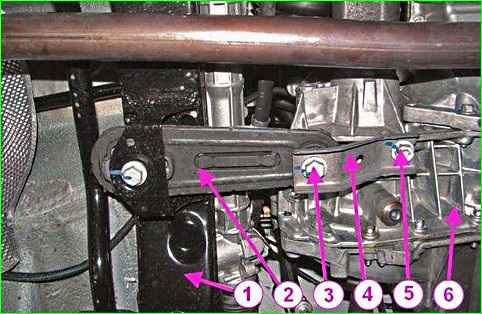

Unscrew and remove bolt 3, figure 1, fastening connecting bracket 4 to lower torque rod 2 (replaceable head 18, extension and ratchet).

Loosen bolt 5 fastening connecting bracket to gearbox housing 6 and turn bracket 4 away from torque rod 2 (replaceable head 18, extension and ratchet).

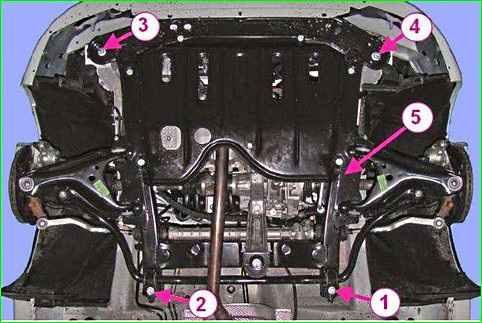

Place the transmission rack under subframe 5, figure 2, of the front suspension, raise the rack stop until it touches the subframe and unscrew bolts 1 - 4 of the subframe mount (replaceable head 18, ratchet, transmission rack).

Lower the transmission rack and remove the subframe from the body. The operation should be performed by two performers.

If necessary, disconnect from the subframe:

- - anti-roll bar;

- - front suspension arms;

- - torque rod of the lower support of the power unit.

Installation

Attention. Reuse of the front suspension subframe mounting bolts is not allowed. The bolts must be replaced.

Attention. Reuse of the ball joint mounting nut to the steering knuckle is not allowed. The nut must be replaced.

If removed, install on the subframe:

- - front suspension arms;

- - anti-roll bar;

- - torque rod of the lower support of the power unit.

Install the subframe on the car and screw in new mounting bolts without tightening. The operation should be performed by two performers (18 mm socket, ratchet wrench, transmission rack).

Finally tighten the subframe mounting bolts in the sequence shown in Figure 2. The bolt tightening torque is 105 Nm (10.5 kgf.m) (18 mm socket, torque wrench).

Install the steering gear on the front suspension subframe and secure with bolts.

The bolt tightening torque is 105 Nm (10.5 kgf.m) (18 mm socket, ratchet wrench, torque wrench).

For vehicles with a K4M engine, install the steering gear heat shield in place and secure with bolts. Tightening torque of bolts 21 Nm (2.1 kgf.m) (replaceable head 13, ratchet wrench, torque wrench).

Secure the oxygen sensor wiring harness in the holder on the heat shield of the steering gear.

Connect the gearbox connecting bracket to the lower torque rod

power unit mounts and tighten the bracket mounting bolts to the gearbox housing and to the torque rod. Tightening torque of bolts 105 Nm (10.5 kgf.m) (replaceable head 18, extension and ratchet).

Secure the low-pressure line with a bolt on the front suspension subframe ki. Tightening torque of the bolt 21 Nm (2.1 kgf.m) (replaceable head 10, ratchet wrench, torque wrench).

Attention. Install the bolt for fastening the ball joint of the lower arm of the front suspension to the steering knuckle with the head facing the front of the car.

Install the pin of the ball joint of the front suspension arm into the steering knuckle, install the fastening bolt and tighten the new nut.

During assembly, the flange of the spacer washer must fit into the slot on the steering knuckle. Tightening torque of the nut 62 Nm (6.2 kgf.m) (ring spanner 16, replaceable head 16, ratchet spanner, torque wrench).

Repeat the operation of connecting the lever to the steering knuckle for the other side.

Install the mounting bolts in the upper holes of the connecting rods of the front suspension subframe and screw them into the corresponding holes of the engine compartment side members. Tightening torque of bolts 21 Nm (2.1 kgf.m) (replaceable head 13, ratchet wrench, torque wrench).

For cars with K7M engine, install a catalytic converter.

Fasten the lower part of the bumper to the front suspension subframe with three mounting screws (replaceable TorxT30 socket, extension, ratchet wrench).

Install the lower and side mudguards of the front fenders.

Install the engine crankcase protection.

Install the front wheels.

Remove the technological fastening belts from the engine cooling system radiator.

Connect the ground wire terminal to the battery (spanner 10).

Check and, if necessary, adjust the installation angles of the front wheels.