The canister purge valve is installed on the air filter housing

The need for inspection and replacement can be determined by the fault code.

To complete the work you will need a multimeter and pieces of wire.

Removing and checking the canister purge valve

We prepare the car for work.

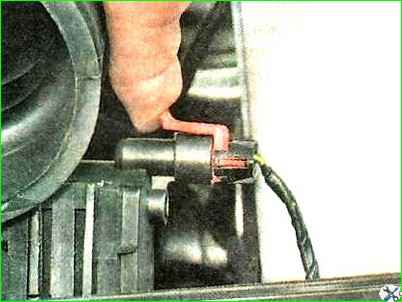

Having released the lock, disconnect the wiring harness block from the canister purge valve (the photo shows it with the air filter cover removed for clarity).

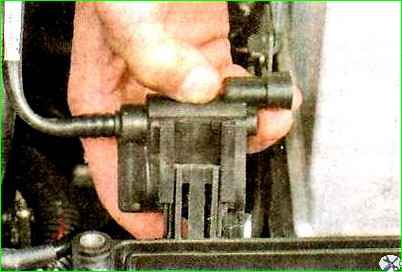

Using a screwdriver, we release the lock, moving the valve up, and remove it from the bracket.

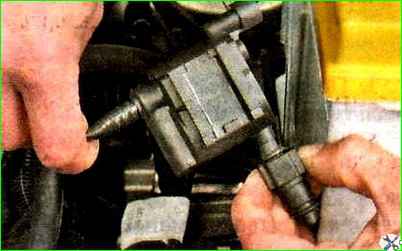

Squeezing the clamp, remove the tip of the tube from the valve nozzle.

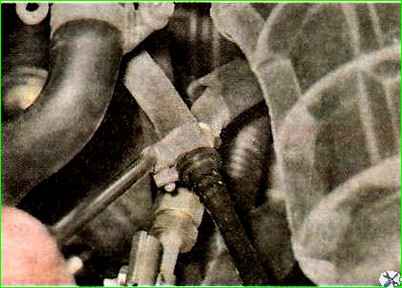

Using a Phillips screwdriver, loosen the clamp securing the hose to the canister purge valve tube.

Using a screwdriver, remove the valve from the adsorber.

We apply 12 V voltage from the battery to the valve terminals (“+” to terminal 2, “-” to terminal 1).

To avoid a short circuit during the following operation, one of the probes should be insulated with a PVC tube.

When voltage is applied to the terminals, the valve should open with a characteristic click.

The faulty valve must be replaced.

Installation

Install the valve in the reverse order of removal.