Usually the bracket and brace are changed after they are deformed as a result of shock loads that occur during emergency situations or during operation on bad roads

In some cases, it is impossible to visually determine the bent of the extension until you dismantle it.

In order to replace the bracket and brace, you need to use an overpass or a lift.

Using a 24mm wrench, unscrew the nut securing the extension to the lever, holding the extension with a 24mm wrench

Remove the thrust washer.

Use a 24mm spanner to loosen the nut securing the brace to the bracket.

Using a 17mm socket, unscrew the three bolts securing the brace bracket to the body.

We remove the rear end of the stretcher from the hole in the lever

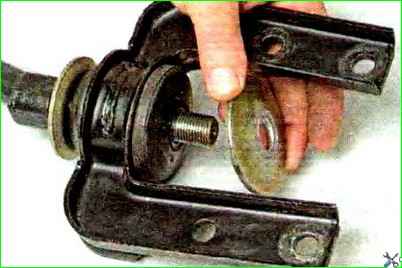

Remove the large washer. At the rear end of the stretcher there are washers for adjusting the longitudinal inclination of the wheel steering axis

Using a 24mm wrench, unscrew the nut securing the front end of the brace to the bracket

Remove the washer

Remove the bracket and large washer from the extension

Behind the large washer at the front end of the extension there are adjusting washers for the caster angle of the wheel rotation axis (in our case there are two washers).

When installing the adjusting washer, it is necessary that the chamfer on its inner edge faces the extension

The longitudinal stretcher has a catalog number: - 2108-2904270.

The longitudinal tension bracket assembly has a catalog number – 1118-2904049

Assembly is carried out in the reverse order, while in order to maintain the longitudinal inclination of the wheel rotation axis, we install the same number of adjusting washers at each end of the stretcher.

We tighten the threaded connections of rubber-metal joints when the car is standing on wheels.

The tightening torque of the wheel bolts is 65-95 Nm (6.5-9.5 kgf m).

Tightening torque:

- - tension fastening nuts - 160-176.4 Nm (16.3-18 kgf m);

- - tension bracket mounting bolts – 42.1-52.0 Nm (4.3-5.3 kgf m).

After replacing the longitudinal extension, you need to check the angles of the front wheels (alignment - camber).

After driving 100 km, tighten the threaded connections again to the required torque.