To check the condition of the wheel bearings, you need to hang the wheel and rotate it by hand

The wheel should rotate evenly, without jamming or knocking

We take the wheel in a vertical plane and alternately pull the upper part toward us, and the lower part away from us, and vice versa. We make sure there is no play.

Usually, when driving, a “squealing” sound is heard from a faulty wheel bearing.

Disassembly

We place the shoes under the front wheels of the car. Loosen the rear wheel mounting bolts.

Raise the rear of the car and place a safety device.

Unscrew and remove the rear wheel. Fully lower the parking brake lever. We loosen the tension of the parking brake cables.

Use a 7 mm socket wrench to unscrew the two guide pins.

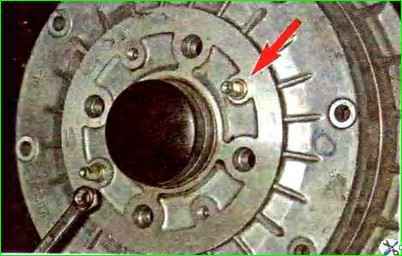

We clean the cylindrical seating surface of the brake drum on the hub from dirt and corrosion.

We treat the drum seat on the hub with penetrating fluid (VD-40, kerosene or brake fluid).

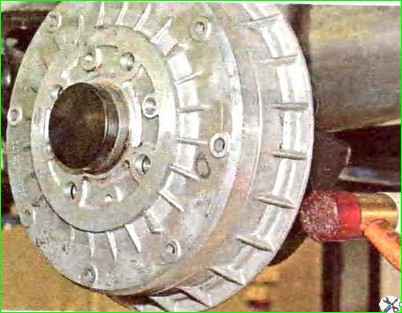

To ensure removal of the drum, tap it with a hammer and a rubber mallet or through a wooden spacer with a hammer.

Using a puller or screwing M8 bolts into the two threaded holes of the drum (the length of the threaded part is 60 - 70 mm) and evenly turning them, we press the drum from the hub.

You can also remove it using a wooden spacer or a hammer with a soft working part.

Tapping the drum from the back, evenly in a circle

To prevent the pistons from falling out of the brake wheel cylinder, do not press the brake pedal with the drum removed.

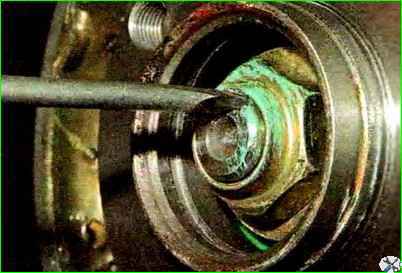

Use a screwdriver and remove the protective cap from the wheel hub.

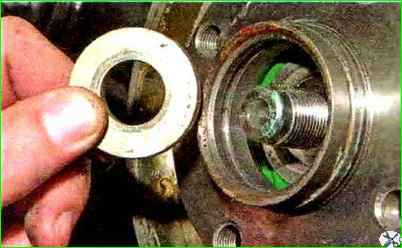

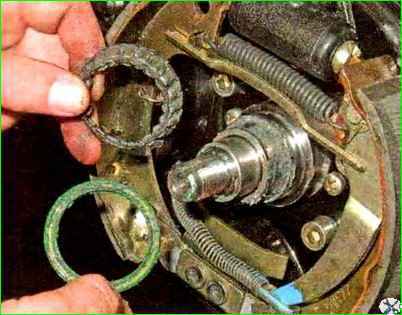

The O-ring remains on the cap

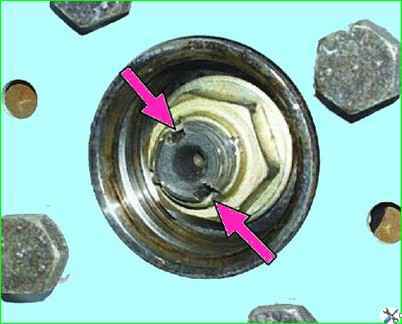

Use a narrow chisel or screwdriver to straighten the jammed nut collar

Use a 30mm socket to unscrew the hub nut

Remove the nut and thrust washer

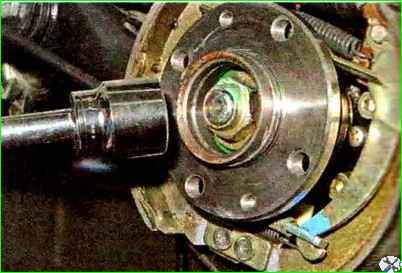

The bearing is mounted on the axle with a transitional fit, so the hub can be removed by hand.

If the hub does not come out by hand, then press the hub with a puller.

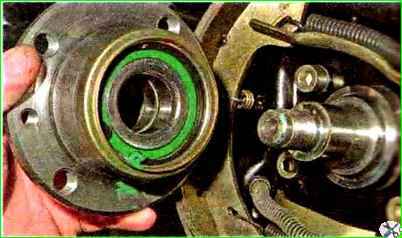

Remove the hub from the axle. In this case, a cage with rollers, a protective ring and an inner ring of the bearing remain on the axis.

Remove several rollers from the bearing cage and remove the cage and protective ring

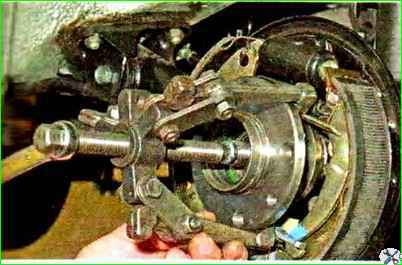

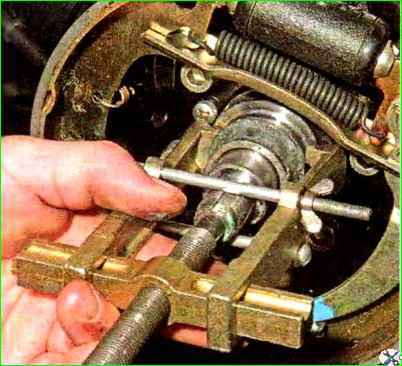

To remove the inner ring of the bearing, there are two flats on the axle for installing a puller.

The flats are located parallel to the brake pad spacer.

Hook the paws of the two-jaw puller onto the inner ring of the bearing.

Press the inner ring of the bearing.

If there is no suitable puller, you can knock down the inner ring with a suitable chisel.

Holding the hub in a vice, remove the retaining ring with pliers.

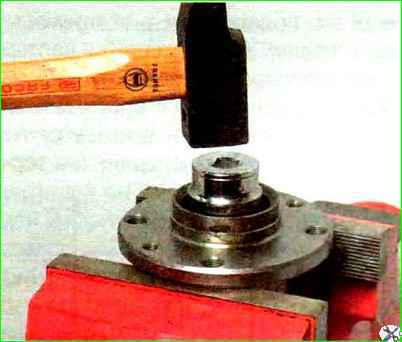

Use a cup puller to press out the bearing.

If there is no puller, we knock out the bearing using a suitable head or a piece of pipe, striking the inner ring of the bearing.

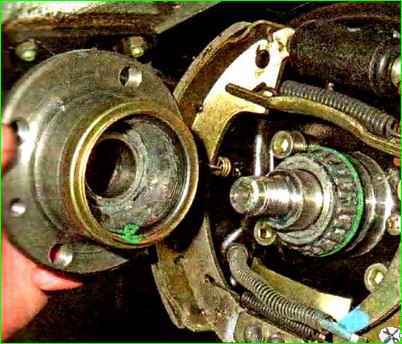

We press in the new bearing using a cup puller, having first cleaned the inner surface of the hub and lubricated it.

If a puller is not available, the bearing can be pressed in a vice by applying force to the outer ring, through the ring from the old bearing.

Installing the retaining ring

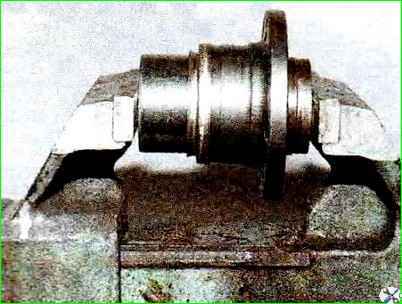

Carefully, with light blows on the inner ring of the bearing, press the hub with the bearing onto the axle to a depth that allows you to tighten the nut.

Tightening the nut, we finally press the hub.

Tightening torque of the hub nut 225-250 Nm (22.5-25 kgcm)

We jam the collar of the nut into the groove of the hub axle

Final assembly is carried out in reverse order.