Remove the steering mechanism (see "Removing the steering column with electric power steering of a Lada Kalina car").

Remove the steering mechanism cover (see "How to replace the steering mechanism cover and the mechanism itself of the Lada Kalina car").

Remove the steering rod support.

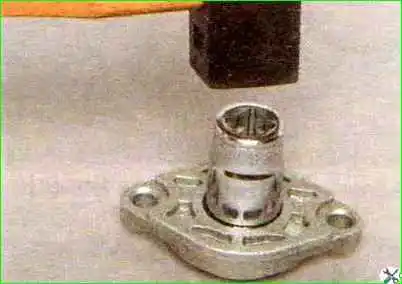

Insert the bit into the groove of the crankcase pipe mounting nut and unscrew the nut, striking the bit (right-hand thread)

Remove the steering gear housing pipe

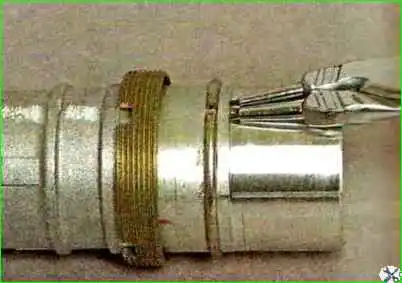

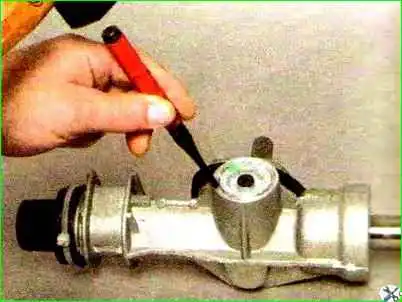

Use a screwdriver to press out the two clamps of the bushing located inside the pipe.

And take out the bushing

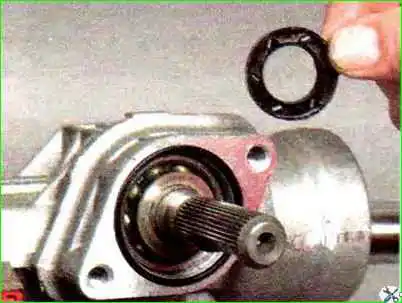

Remove the two rubber O-rings from the bushing

Steering rack bushing (arrows indicate clamps)

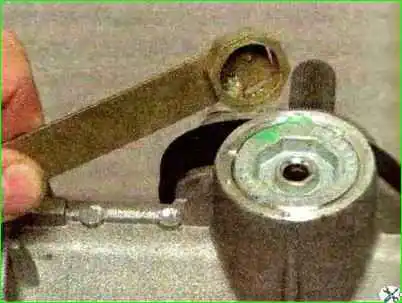

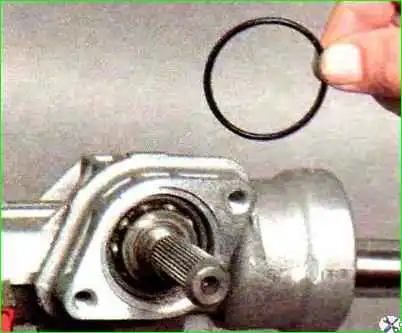

If it is necessary to replace the nut, use circlip pliers to unscrew and remove the circlip.

Remove the pipe fastening nut

Remove the rubber plug from the adjusting nut of the rack stop.

Use a scraper to remove the jammed metal in the places where the stop adjusting nut is locked

Use a special 24mm wrench with an external octagonal head to unscrew the stop nut

Remove the stop spring

Use a screwdriver to remove the sealing ring

By hitting the crankcase against a wooden block, we knock out the rack stop.

Use a screwdriver to remove the liner from the stop

A rubber sealing ring is installed in the groove of the stop

Remove the rubber ring from the crankcase that seals the hole for the steering mechanism on the front panel

Remove the boot from the gear shaft

Use a 6mm hex to unscrew the two screws

And remove the crankcase cover

Remove the cage with the thrust bearing rollers

Remove the sealing ring of the cover

Remove the rack from the crankcase

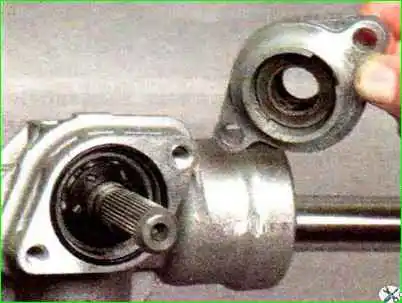

We press out the gear shaft by holding the shaft in a vice with soft metal jaw linings and pressing the crankcase up with the mounting blade

Remove the gear shaft with bearing from the crankcase

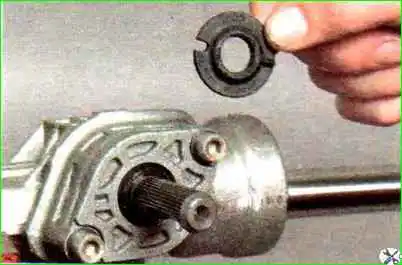

Pry up with a screwdriver and remove the retaining ring of the bushing

Remove the gear shaft bushing complete with the support plate.

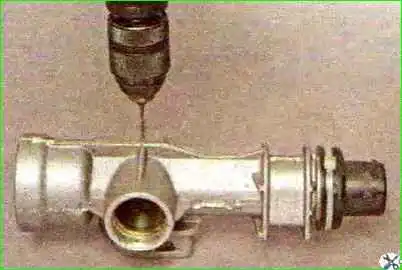

If it is necessary to replace the needle bearing, use a 4 mm drill to drill two diametrically located holes in the crankcase so that they extend to the end of the outer ring of the needle bearing.

Through the drilled holes, using a rod of the appropriate diameter, knock out the outer ring of the bearing from the crankcase

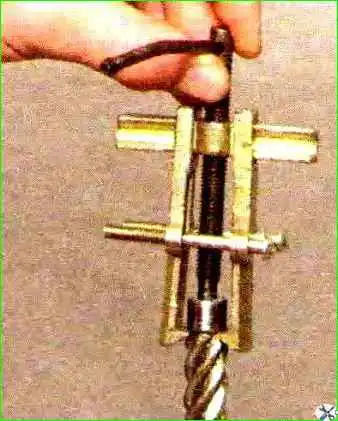

We use a puller to press the ball bearing of the gear shaft from the internal m ring of the roller thrust bearing.

Use a puller to press the inner ring of the needle bearing from the shaft.

Use a screwdriver to pry and remove the gear shaft oil seal from the crankcase cover.

If it is necessary to replace the outer race of the roller thrust bearing

Use a scraper to remove the extruded metal in four places and remove the ring.

Assembly

Lubricate the bearings, rack and gear teeth, and plastic rack bushing with Fiol-1 grease.

Assemble the steering mechanism in reverse order

We press the outer ring of the needle bearing into the crankcase using a mandrel of suitable diameter.

To seal holes in the crankcase, you can use “fast steel” or “cold welding.”

We press the gear shaft with the ball bearing into the crankcase using a piece of pipe of a suitable diameter or a high head, applying force to the outer ring of the bearing.

You can press the gear shaft into the crankcase, resting the outer ring of the bearing on the jaws of a vice.

Then we put the crankcase on the bearing

And press the crankcase with light blows of a hammer through a wooden block

Press the gear shaft oil seal into the cover through a mandrel or head flush with the end of the cover

Insert the rack into the steering gear housing. We install the pipe so that the flat on it is located on the right side.

Move the rack so that the steering rod support mounted on the rack is located in the middle of the pipe groove.

Insert the rack stop, the stop spring and tighten the stop nut.

It is recommended to replace the stop nut with a new one.

Having adjusted the gap in the engagement of the gear with the rack, tighten the stop nut.

After tightening the nut, tighten it