Front wheel drive seals can be replaced without removing the gearbox

We carry out the work on an inspection ditch or overpass.

Drain the oil from the gearbox.

Remove the left and right front wheel drives (see "Removing the front wheel drives").

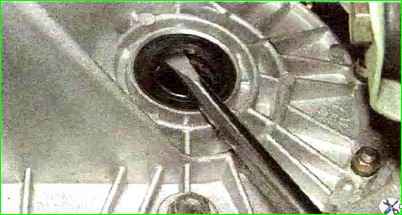

Use an impact puller to press out the right drive oil seal.

Press out the left drive oil seal in the same way.

If there is no impact puller, you can press it out with a mounting blade.

The gearbox can be equipped with two types of oil seals: both with and without oil drainage notches.

Seals without notches are interchangeable for left and right drives. Seals with notches differ:

- at the left drive oil seal the arrow on the housing points counterclockwise, at the right drive it points clockwise

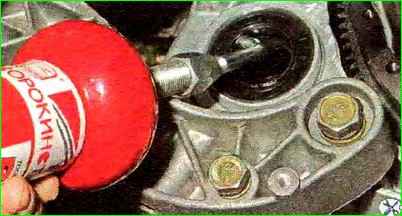

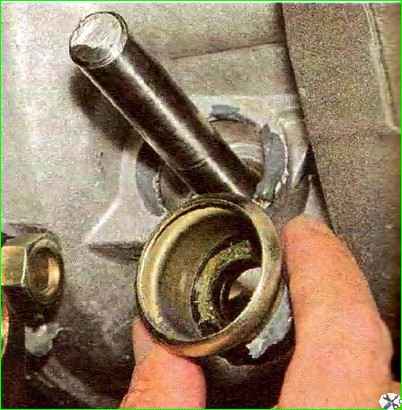

Using a mandrel of suitable diameter, press in a new oil seal for the right wheel drive.

You can use the old oil seal as a guide when pressing.

We press in the left wheel drive oil seal in the same way.

Apply a thin layer of transmission oil to the working edges of the oil seals

Replacing the gear shift rod hinge boot and rod seal

Move the protective cover from the gear selector rod hinge.

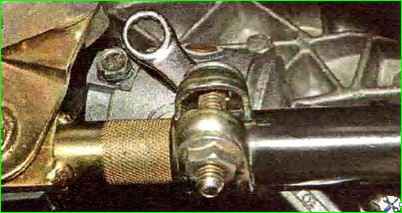

Use a 10mm spanner to unscrew the hinge locking screw.

Remove the screw

We move the joint assembly with the control rod from the gear selector rod.

Remove the protective cover of the hinge from the switch rod

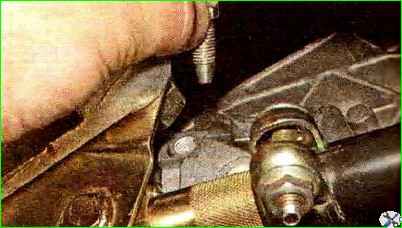

Using a powerful slotted screwdriver, pry the oil seal holder evenly from different sides

Press out the race with the oil seal from the clutch housing socket

Using a mandrel of a suitable size, press the oil seal out of the holder

We clean the race and the seat under it in the clutch housing from the old sealant.

Select a mandrel (for example, a tool head) with a diameter close to the outer diameter of the oil seal.

Press the oil seal into the cage until it stops (the working edge of the oil seal must face the clutch housing)

Apply transmission oil to the working edge of the oil seal, and sealant to the outer surface of the race.

We put the cage on the switch rod and press it into the clutch housing socket, resting with a mandrel of a suitable size on the collar of the oil seal cage.

We carry out further assembly in reverse order.

Replace the damaged hinge cover.

Before assembly, clean and degrease the threads of the hinge locking screw and apply sealant to the threads.

Before tightening the screw, ensure that the holes in the hinge and the gear selector rod match.