Method of checking pressure in the line:

Put the car on the lift and apply the parking brake.

If necessary, start the engine and warm up the car so that the temperature of the automatic transmission fluid reaches a temperature of 50 ± 80˚С.

Check the transmission oil level.

Add more if necessary.

Raise the car on a lift to a height convenient for performing work.

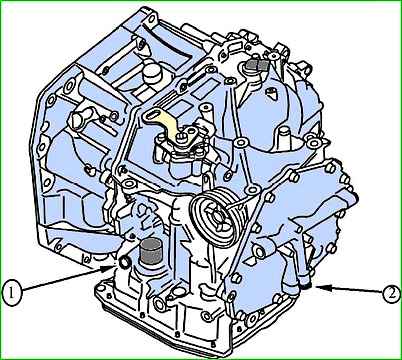

Unscrew plug 1 or 2, and tighten the fitting M10x1.0 of the Bourdon pressure gauge.

When installing the pressure gauge, use the sealing ring of the plug.

Start the engine.

Measure the pressure in the line at idle and when slipping.

When taking measurements in positions “D”, “1”, “2” and “R” of the range switch, keep the brake pedal pressed.

The pressure in the line must correspond to the values given in the table.

If the line pressure does not correspond to the values given in the table, see the line pressure diagnostic table.

Control the slipping mode with the brake pedal and parking brake pressed, pressing the accelerator pedal until the engine speed stops increasing.

Measure pressure in slip mode for no more than 5 seconds.

After measuring the pressure in slip mode, let the engine idle for 1 minute in the “P” or “N” positions of the range switch.

Unscrew the fitting of the Bourdon pressure gauge.

Install a new O-ring on the plug, lubricate it with transmission oil, screw in and tighten the plug.

Plug tightening torque 7.4 Nm (0.74 kgf.m).

Table. Pressure in the line, MPa (kg/cm 2)

Mode - Positions "D", "1", "2" - Position "R":

- Idling - 0.41 (4.18) - 0.57 (5.81);

- Slip - 1.4 (14.28) - 2.14 (21.83)

Diagnostics of pressure in the line

Mode - Pressure value - Possible reasons

Idling

Low line pressure for all gear ranges (“R”, “D”, “2”, “1”) - Malfunctions in the line pressure control system or low oil pump performance:

- - wear of the oil pump;

- - jamming of the pressure control valve or wear of its spring;

- - oil leakage from the oil pressure control valve channel;

- - reduced engine speed at idle.

Low line pressure only for certain gear ranges - Loss of oil pressure in the line or in the device associated with the position of the gear selector after the pressure is distributed by the manually operated valve

High line pressure - Malfunction of the accelerator pedal position sensor or the line pressure control function:

- - the accelerator pedal position does not correspond to the idle mode;

- - malfunctions in the operation of the EKRDM (sticking in the open position, open circuit of the EKRDM control circuit);

- - jamming of the pressure control valve;

- - increased engine speed at idle.

Slip

The pressure in the line does not rise above the pressure in the line at idle.

Malfunctions in the operation of the line pressure regulation function:

- - malfunction of the automatic transmission control controller;

- - malfunctions in the operation of the EKRDM (sticking in the closed position, short circuit in the EKRDM control circuit);

- - jamming of the pressure control valve.

The pressure is higher than in idle mode, but below the set value - Malfunctions in the operation of the line pressure regulation function:

- - wear of the oil pump;

- - malfunctions in the operation of the EKRDM (sticking in the open position, open circuit of the EKRDM control circuit);

- - jamming of the pressure control valve.

Low line pressure only for certain gear ranges - Loss of oil pressure in the line or in the device associated with the position of the gear selector after the pressure is distributed by the manually operated valve