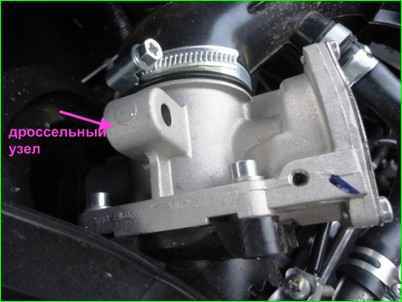

The throttle valve is turned by an electric motor through a gearbox. Both are built into the throttle body

When starting and warming up the engine, as well as in idling mode, the flow of air into the cylinders is regulated by opening the throttle valve.

The throttle position is controlled by two sensors built into the throttle body.

The throttle valve opening angle is set by the electronic control unit (ECU) depending on the estimated amount of air that should enter the engine cylinders.

This takes into account the operating mode of the engine (starting, warming up, idling, and so on), the temperature of the ambient air and the engine, and the position of the gas pedal.

Control commands are sent to the throttle assembly to the electric motor.

At the same time, the ECU monitors the opening angle of the damper and, if necessary, sends appropriate commands to adjust its position.

As a result of the fact that the ECU simultaneously regulates the amount of injected fuel and incoming air, the optimal composition of the combustible mixture is maintained in any engine operating mode.

The electric throttle body is sensitive to deposits that may accumulate on its internal surface.

The resulting layer of deposits can interfere with the smooth movement of the throttle valve, jamming it (especially at low opening angles).

As a result, the engine will operate unstably and even stall at idle, start poorly, and failures may appear during transient conditions.

To avoid this, as a preventive measure, deposits should be removed with special detergent compounds during regular vehicle maintenance.

A large layer of deposits can completely block the movement of the damper.

If flushing fails to restore the throttle assembly’s functionality, it must be replaced.

Removal and installation of a throttle assembly with an electronic throttle valve drive is described in the article - "Checking the throttle assembly"

A malfunction or incorrect operation of the throttle assembly may be caused by a broken contact in its electrical circuit (oxidized terminals in the connecting block of the wiring harness).

In this case, it will be possible to restore operation by treating the terminals with a special compound for cleaning and protecting electrical contacts.

Other causes of the malfunction are possible:

- - no supply voltage is supplied to the throttle assembly;

- - signals are not received from both throttle position sensors;

- - The computer cannot recognize signals from the throttle position sensors.

In these cases, the engine control system goes into emergency mode.

At the same time, the car retains the ability to independently move a short distance at a slow speed, which, in extreme cases, will allow it to be moved to a safe place (pull to the side of the road, leave an intersection, etc.).

The fact that the throttle assembly is operating in emergency mode may be indicated by a burning indicator lamp for a malfunction of the engine management system and an increased speed of the crankshaft at idle (about 1500 min -1, despite the fact , that the engine is warmed up to operating temperature), the engine will not respond to pressing the gas pedal.

Each of the throttle position sensors is a potentiometer.

During operation, gradual wear of conductive paths and moving contacts occurs.

Over time, wear may reach such an extent that correct operation of the sensor becomes impossible. The presence of two sensors increases the reliability of the entire node.

If only one sensor fails, the warning lamp will light up, but the engine management system will switch to backup mode.

In this case, the engine will respond adequately to pressing the gas pedal, but with worse performance parameters

Standby mode allows you to drive your car to the repair site under your own power.