Throttle assembly - removal, inspection, cleaning and installation of Lada Granta

The throttle assembly is non-separable, cannot be repaired and in case of malfunction it is replaced as an assembly

The need for work is determined during a check of the technical condition of the engine control system.

To flush the throttle assembly, you need a means to clean the engine inlet pipeline.

As a last resort, you can use a carburetor cleaner.

If the problem cannot be eliminated using a cleaner, the throttle assembly must be replaced.

After removing the throttle assembly, the gasket (O-ring) must be replaced.

A product may be required to clean and protect electrical contacts.

To avoid damaging the electric drive, do not try to forcefully turn the throttle valve by applying force to it.

When installing a new throttle assembly on a vehicle, special diagnostic equipment will be required in order to check the “calibration” of the throttle position in the extreme positions.

We prepare the car for work and disconnect the wire terminal from the negative terminal of the battery.

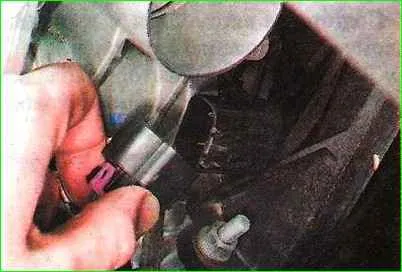

Using a Phillips screwdriver, loosen the clamp and disconnect the air supply hose from the throttle body pipe and take the hose down.

Pressing the clamps, disconnect the wiring harness block from the throttle assembly.

Visually check the condition of the throttle assembly terminals and the wiring harness block.

To remove oxides, spray the terminals with a product for cleaning and protecting electrical contacts.

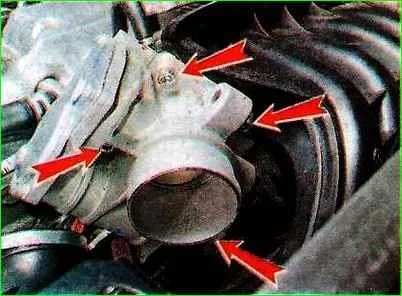

Use a 5 mm hex wrench to unscrew the four bolts securing the throttle assembly (one of the bolts is not visible in the photo)

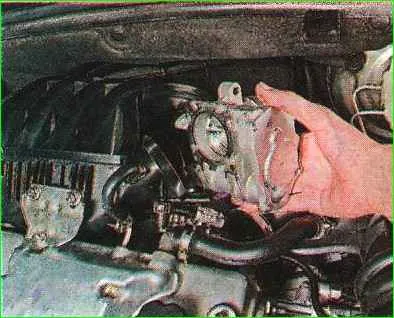

Remove the throttle assembly

Remove the sealing ring from the intake manifold receiver flange

Using a multimeter in ohmmeter mode, measure the resistance of the throttle position sensors between terminals 1 and 4.

A working throttle assembly should have a resistance in the range of 750-1250 Ohms.

When performing the following operation, hold the throttle assembly with the electric drive upward so that the cleaning agent cannot flow down the throttle valve axis towards the gear motor and get inside the mechanism.

Use a cleaning agent to wash away deposits from the inner walls of the throttle assembly and from the throttle valve.

Wipe the throttle assembly with a clean rag and blow it with compressed air from a compressor or foot pump.

Install the throttle assembly in reverse order, replacing the O-ring with a new one.

Pin assignments of the throttle assembly - Pin number - Electrical circuit of the throttle assembly - Pin assignment

Throttle position sensors:

- 1 - “Mass”

- 2 - Signal from sensor No. 1

- 3 - Signal from sensor No. 2

- 4 - Supply voltage

Gear motor for throttle valve drive:

- 5 - Motor winding output*

- 6 - Motor winding output*

* The polarity of the power supply voltage supplied to the electric motor changes depending on the direction in which the throttle valve needs to be turned