The Lada Granta has two oxygen sensors

The oxygen concentration control sensor is installed in the upper part of the catalytic collector

Oxygen contained in the exhaust gases reacts with the oxygen sensor, creating a potential difference at the sensor output.

It varies from approximately 0.1 V (high oxygen - lean mixture) to 0.9 V (low oxygen - rich mixture)

For normal operation, the sensor must have a temperature of at least 360°C. Therefore, for quick warm-up after starting the engine, a heating element is built into the sensor.

By monitoring the output voltage of the oxygen concentration sensor, the controller determines which command to adjust the composition of the working mixture to send to the injectors.

If the mixture is lean (low potential difference at the sensor output), then a command is given to enrich the mixture.

If the mixture is rich (high potential difference), a command is given to lean the mixture.

The diagnostic oxygen concentration sensor is installed in the catalytic collector behind the converter; it operates on the same principle as the control sensor and is completely interchangeable with it.

The signal generated by the diagnostic oxygen concentration sensor indicates the presence of oxygen in the exhaust gases after the converter.

If the converter is working normally, the diagnostic sensor readings will differ significantly from the control sensor readings.

Replacing the diagnostic oxygen concentration sensor is carried out in the same way as replacing the control sensor.

The consequence of a malfunction of the lambda probe is an increase in the threshold of exhaust gas toxicity allowed by the on-board diagnostic system for HC, CO emissions.

Oxygen sensors can have two types of malfunction:

- - mechanical failure of one of the electrical components (electrical failure);

- - a malfunction of the chemical component, this leads to an increase in the response time of the sensor and, consequently, to an increase in the response period.

If the sensor malfunctions, fuel consumption will increase, engine power will decrease, and idling will be unstable. The exhaust gas catalytic converter may be damaged.

To complete the work, you will need a multimeter (in voltmeter mode), an inspection ditch or overpass (to remove the lower sensor) and a special key for the oxygen sensor.

Checking the oxygen sensor

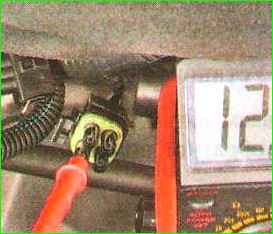

Pressing the spring clip, disconnect the wiring harness block from the oxygen concentration sensor block.

Turn on the ignition.

Check the supply voltage of the heating element at terminal “B” (the designation of the terminals is marked on the wiring harness block)

Connect the negative probe of the voltmeter to the engine ground

The voltage at the output must be at least 12 V.

If the voltage does not reach the block or it is less than 12 V, it means that the battery is discharged, the power circuit is faulty, or the ECU is faulty.

Connect the “negative” probe of the voltmeter to terminal “C”.

Measure the voltage between terminals “A” and “C”.

The voltage at the terminals should be 0.45 V.

If the voltage does not reach the block or it differs by more than 0.02 V, then the power circuit is faulty or the electronic control unit is faulty.

Removal and installation

The oxygen concentration control sensor is located in the upper part of the catalytic collector.

The sensor is covered by the receiver and the engine intake pipe, but it can be removed from above from the engine compartment.

Showing with the receiver and intake pipe removed

Squeeze the antennae of the plastic holder for the sensor wires and remove the holder from the hole in the heat shield of the steering mechanic ism

Disconnect the wire blocks

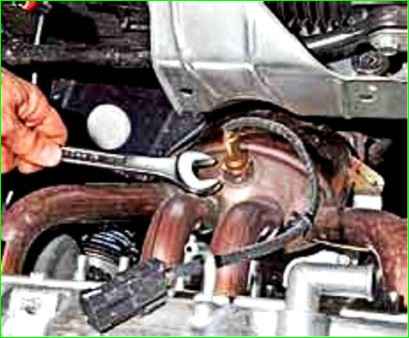

Using a 22mm open-end wrench, unscrew the sensor from the threaded hole in the catenary collector.

During operation, the sensor may become stuck to the catalytic collector and then it will be difficult to unscrew the sensor with an open-end wrench. You can unscrew the sensor with a spanner wrench.

Then you need to disassemble the block or cut the wire going to the sensor if the sensor needs to be replaced.

You can also cut a slot in the spanner and thread a wire through it.

Remove the control oxygen concentration sensor

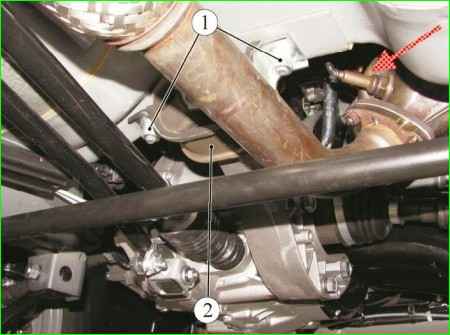

Unscrew the diagnostic sensor from below, placing the car on a lift or inspection ditch.

Remove the middle mudguard of the engine compartment

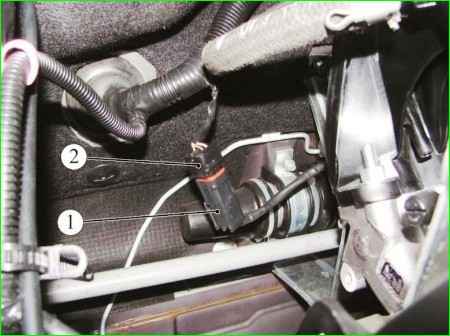

The wiring block is connected in the engine compartment, next to the bulkhead (above the central part of the steering mechanism)

Having released the lock of the engine control system wiring block, disconnect the block from the wiring block of the diagnostic oxygen concentration sensor

Using a 22mm wrench, unscrew the sensor from the threaded hole in the collector

Given the location in a hard-to-reach place, it is better to unscrew the sensor using a Z-shaped spanner wrench 22

Having removed the rubber holder of the sensor wiring harness from the hole in the heat shield of the steering mechanism, we thread the wiring harness block through the hole

Removing the diagnostic oxygen concentration sensor

Install the control and diagnostic oxygen concentration sensor in reverse order

Before installing the sensors, apply a thin layer of graphite lubricant to the threaded part of the sensors.

Tighten the sensor to a torque of 40–45 Nm.